36

Model Code Page

21. Engine

205-- 555 210 16

1. 12. 1986

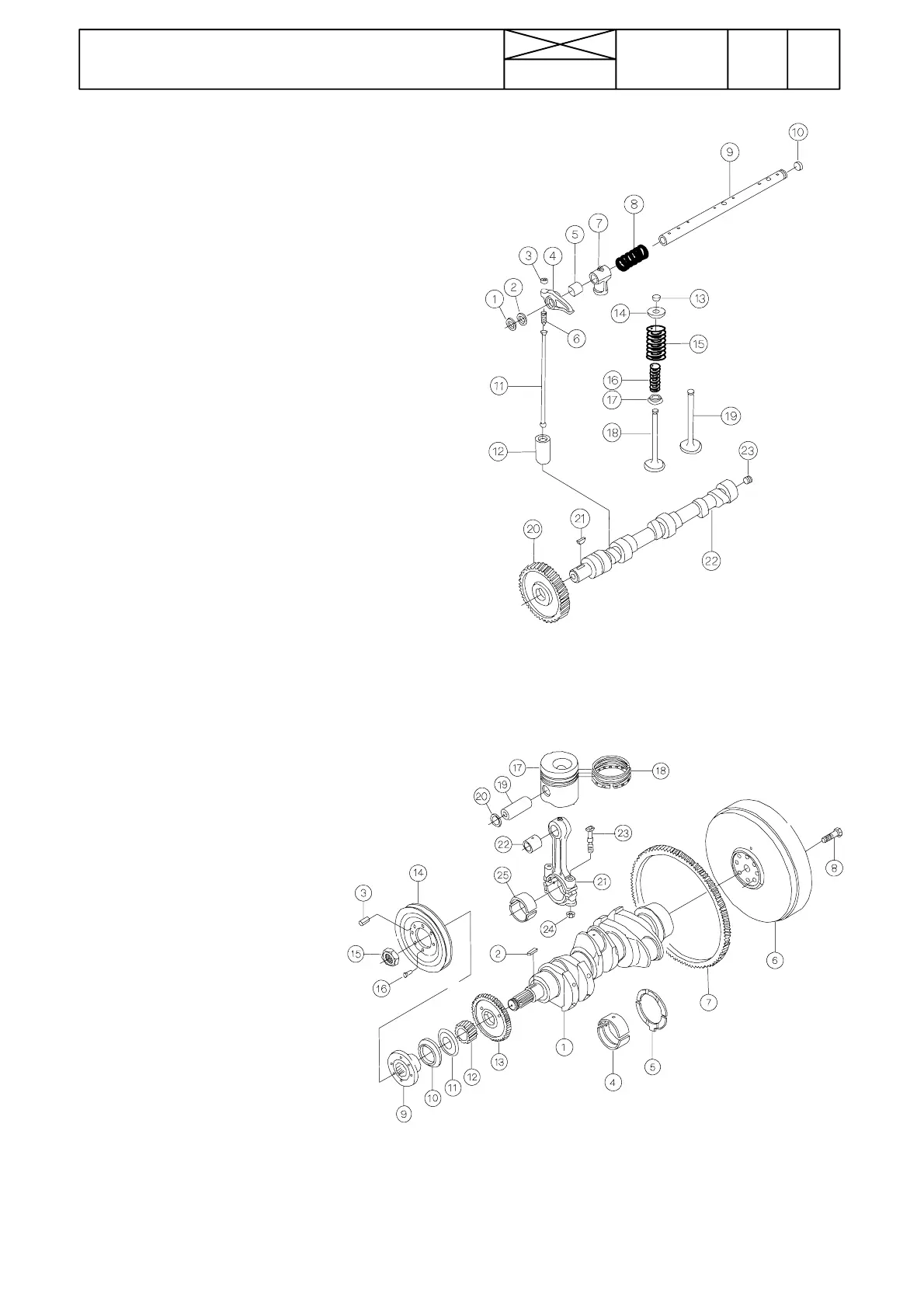

Valve mechanism

1. Circlip

2. Shim

3. Nut

4. Rocker arm

5. Bearing sleeve

6. Adjusting screw

7. Holder

8. Spring

9. Shaft

10. Plug

11. Pushrod

12. Tappet

13. Valve keepers

14. Spring guide

15. Valve spring

16. Valve spring

17. Spring guide

18. Exhaust valve

19. Inlet valve

20. Gear wheel

21. Key

22. Camshaft

23. Threaded plug

The valve mechanism is operated by the camshaft (22) which

is located in the cylinder block. The drive is transferred with

the help of tappets(12) and pushrods (11). The camshaft gear

wheel (20) is fitted with a press fit and fixed with a key (21).

Each bearings is lubricated by the force feed lubrication sys-

tem through drilled oilways in the camshaft.

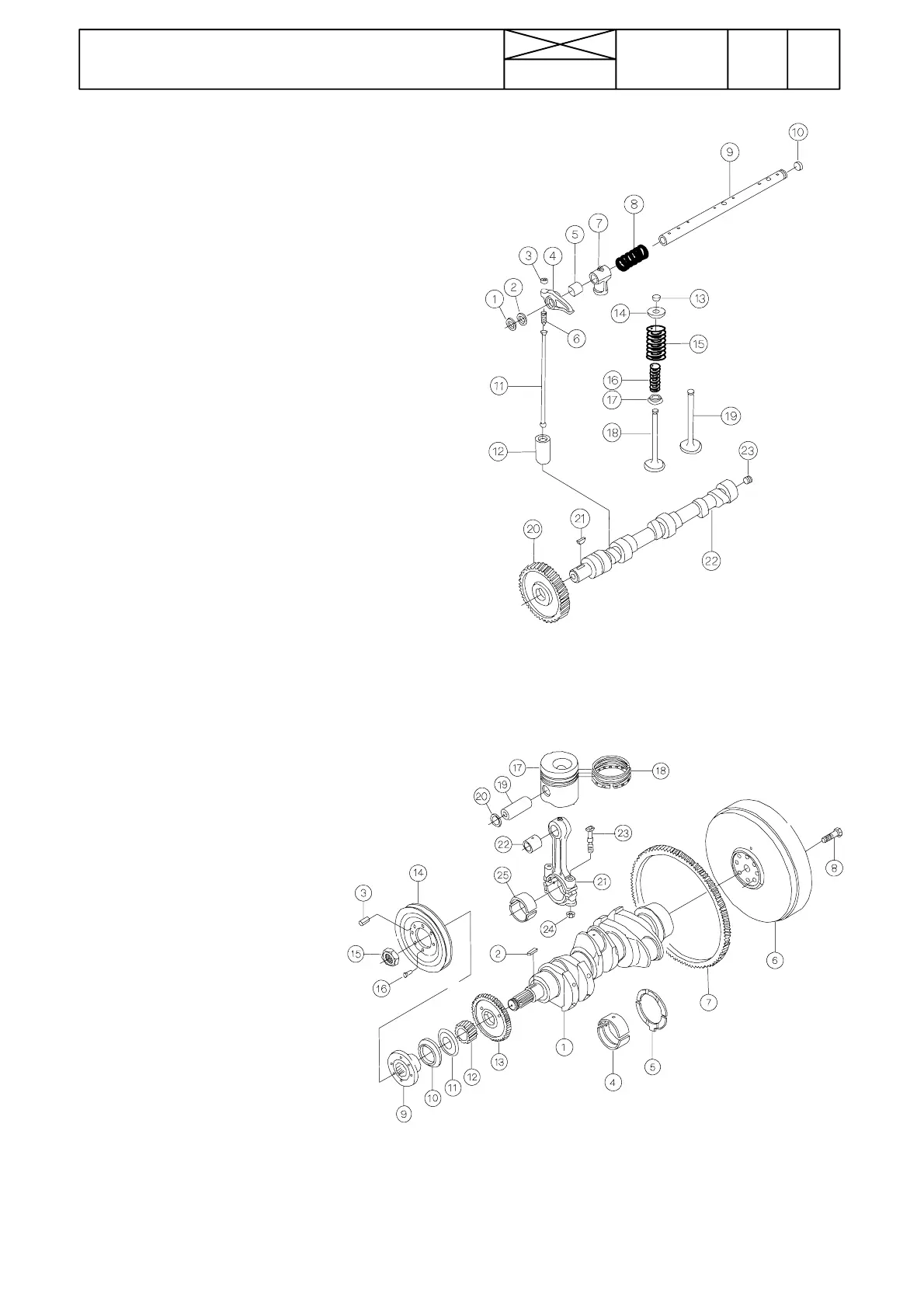

Crank mechanism

1. Crankshaft

2. Key

3. Cylindrical pin

4. Main bearing

5. Thrust bearing

6. Flywheel

7. Ring gear

8. Bolt

9. Hub

10. Shaft seal boot

11. Deflector ring

12. Gear wheel

13. Gear wheel

14. V ---belt pulley

15. Nut

16. Socket head bolt M8x16

17. Piston

18. Piston rings

19. Piston pin

20. Retaining ring

21. Connecting rod

22. Bearing bushing

23 Bolt

24. Nut

25. Crankshaft bearing

The crankshaft (1) is forged from chrome alloy special steel

and is inducti on hardened at the bearing and sealing sur-

faces. Gear wheels (12 and 13) are located at the front end of

the crankshaft. They are fitted with a press fit, and drive the

idler wheel and oil pump. In addition, the front end of the

cr a nk ---

shaft has splines for the hub (9) of the V---belt pulley (14). An

oil deflector ring (11) is fitted between the hub and the gear

wheel, and a dust shield (10)is fitted to the hub in order to seal

the shaft.

Loading...

Loading...