14 15

SERVICE

1. Service must be performed only by qualied repair personnel. Service or maintenance

performed by unqualied personnel may result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance Section of this manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

TROUBLESHOOTING GUIDE

Always be sure that the tool is switched off and has been disconnected from the power source

before making any adjustments or performing any maintenance

procedures.

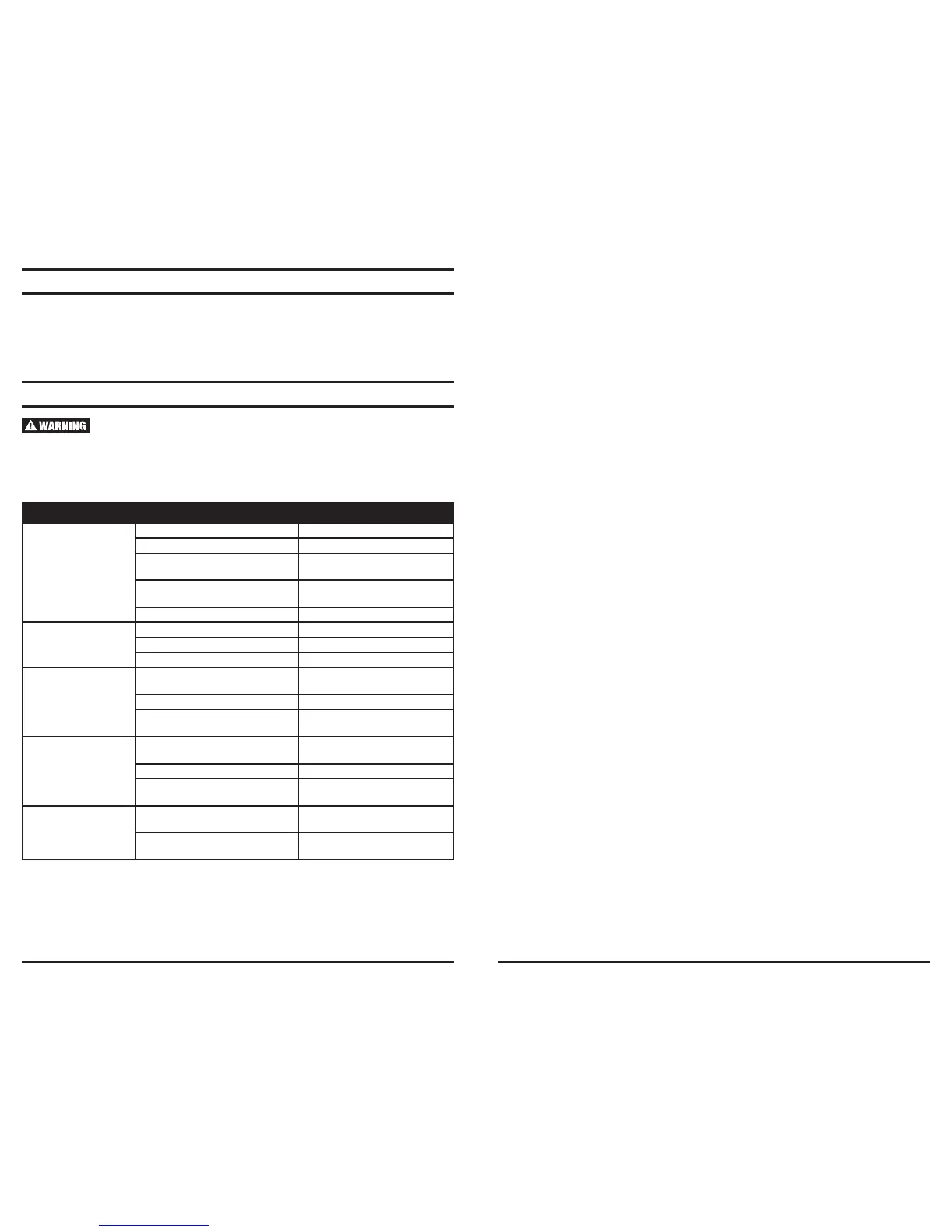

Problem Encountered Possible Cause Corrective Action

No output Power cord not plugged in Plug cord into outlet

Fuse blown or circuit breaker has tripped Replace fuse or reset circuit breaker

Power cord damaged Use authorized service center to repair or

replace power cord

Faulty switch Use authorized service center to repair or

replace switch

Overload protection system engaged Wait for unit to cool then try again

Bad wire-feed Insufcient pressure Tighten tension nut

Loose wing nut Tighten wing nut

Wire has become oxidized Replace wire spool

Not enough current Low input voltage Make sure input voltage matches input

voltage rating requirements

Loose connection Check ground cable solid connection

Damaged rectifying element(s) Use authorized service center to repair or

replace rectifying element(s)

Porous welds Insufcient gas Check gas cylinder, regulator unit and gas

line ttings for proper connection

Hole blocked Use compressed air to clear blockage

Bad gas or wire Check that gas is clean and dry

Use correct wire

Welder does not operate

when depressing switch

Control wire damaged Use authorized service center to repair or

replace control wire

Circuit plate damaged Use authorized service center to repair or

replace circuit plate

Loading...

Loading...