Universal controller TCI-W13-U-H/TCI-W23-U-H

Universal controller TCI-W13-U-H/TCI-W23-U-H

Universal controller TCI-W13-U-H/TCI-W23-U-H

Doc: 70-00-0384A V1.0 20160523 © Vector Controls GmbH, Switzerland Subject to alterations

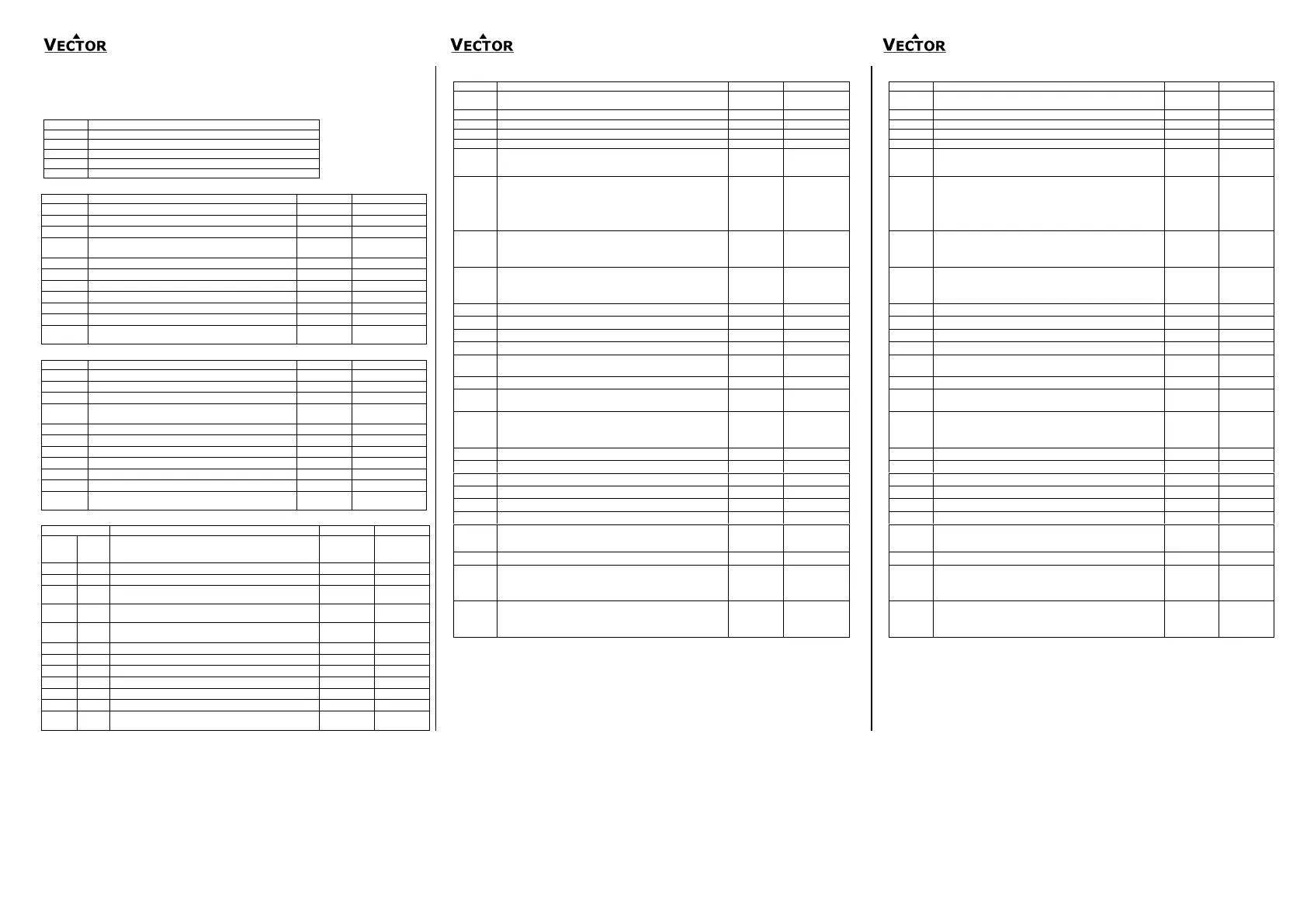

Control parameters (password 241)

Warning! Only experts should change these settings! The parameters are grouped according to

control modules. After completing the logging in, a control module must be selected before

accessing the parameters.

Input configuration: 1T, 1H, 1U, 2T

Analog output configuration, AO1, AO2

Binary output configuration, do1

Internal input configuration (TI1)

Sensor sampling rate(control speed decrease as rate

increases)

Alarm 1 low limit (1T), alarm 3 low limit (1H)

Alarm 1/3 low limit values

Alarm 2high limit (1T), alarm 4high limit (1H)

Alarm 2/4 high limit values

Hysteresis alarm 1, 2, 3, 4

Calculate a range of inputs (0= not active):

1= average, 2= minimum, 3= maximum

Internal input configuration (HI1)

Sensor sampling rate(control speed decrease as rate

increases)

Alarm 1 low limit (1T), alarm 3 low limit (1H)

Alarm 1/3 low limit values

Alarm 2high limit (1T), alarm 4high limit (1H)

Alarm 2/4 high limit values

Hysteresis alarm 1, 2, 3, 4

Calculate a range of inputs (0= not active):

1= average, 2= minimum, 3= maximum

External input configuration (UI1, TI2)

Signal type (0= not active):

1= 0...10V or 0...20mA or open contact, 2= 2...10 V or

4…20 mA, 3= NTC temperature sensor

Analog input display range:

0= x0.1, 1= x1, 2= x10, 3 = x100

Analog input unit of measure:

0= no unit, 1= %, 2= °C /°F, 3= Pa

Sensor sampling rate

(control speed decrease as rate increases)

Alarm 5 low limit (1u), alarm 7 low limit (2t)

Alarm 5 low limit value (1u), alarm 7 low limit value (2t)

Alarm 6 high limit (1u), alarm 8 high limit (2t)

Alarm 6 high limit value 1u), alarm 8 high limit value (2t)

Hysteresis alarm 5 and 6 (1u), alarms 7 and 8 (2t)

Calculate a range of inputs (0=not active):

1= average, 2= minimum, 3= maximum, 4= differential

LP: Control parameters (1L)

Select loop control input (0= loop disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2T

Minimum set point limit heating

Maximum set point limit heating

Minimum set point limit cooling

Maximum set point limit cooling

Enable set point compensation (0= disabled)

1= winter compensation, 2= summer compensation, 3= winter

and summer

Loop input special (0= normal):

1= combine loop 1 and loop 2

2= cascade with reverse sequence of primary loop

3= cascade with direct sequence primary loop

4= cascade with both reverse and direct sequence of

primary loop

Economy mode set point shift: (Function depends on 1L25)

The comfort (occupied) set point is shifted by the value set with

parameter. Reduces the heating set point and increases the

cooling set point.

Dead zone between heating and cooling set points

The dead zone span lies between the heating and the cooling set

point. The output is off while the measured value is within the

dead zone span. A negative dead zone is not possible.

Offset for heating PI sequence

Offset for cooling PI sequence

Integral gain heating (0.1 steps)

low= slow reaction, high= fast reaction

Integral gain cooling (0.1 steps)

Measuring interval integral (seconds)

low= fast reaction, high value= slow reaction

Action of stages:

0= cumulative: stage 1 stays on when 2 on comes on

1= single: stage 1 turns off when 2 on comes on

2= digital: stage 1 only, stage 2 only, then stage 1 plus 2

Offset for heating/reverse binary sequences

Offset for cooling/direct binary sequences

Activation of reverse/direct (heat/cool) sequence

OFF= activates based on demand

ON = follows heat/cool state of controller

Delay for heat /cool changeover when L23=OFF

Fixed set point in standby mode

OFF = Standby set point shift applies

ON = In standby mode use minimum set point limit as set point in

heating mode or maximum set point limit in cooling mode

Set point compensation range, the maximum range the set point

is shifted.

0 = Temperature setback: the set point is shifted towards set point

limit

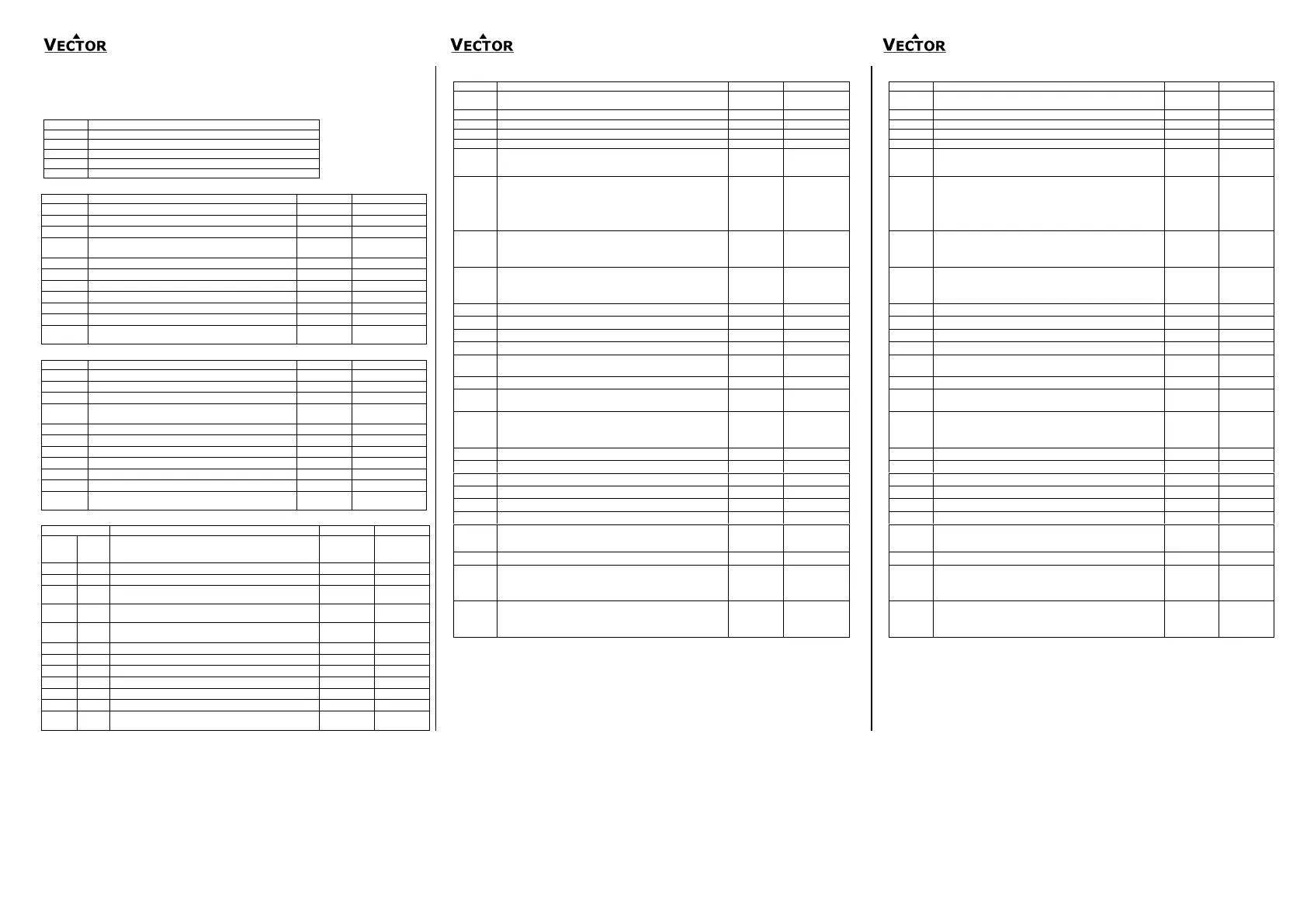

LP: Control parameters (2L)

Select loop control input (0= loop disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2T

Minimum set point limit heating

Maximum set point limit heating

Minimum set point limit cooling

Maximum set point limit cooling

Enable set point compensation (0= disabled)

1= winter compensation, 2= summer compensation, 3= winter

and summer

Loop input special (0= normal):

1= combine loop 1 and loop 2

2= cascade with reverse sequence of primary loop

3= cascade with direct sequence primary loop

4= cascade with both reverse and direct sequence of

primary loop

Economy mode set point shift: (Function depends on 2L25)

The comfort (occupied) set point is shifted by the value set with

parameter. Reduces the heating set point and increases the

cooling set point.

Dead zone between heating and cooling set points

The dead zone span lies between the heating and the cooling set

point. The output is off while the measured value is within the

dead zone span. A negative dead zone is not possible.

Offset for heating PI sequence

Offset for cooling PI sequence

Integral gain heating (0.1 steps)

low= slow reaction, high= fast reaction

Integral gain cooling (0.1 steps)

Measuring interval integral (seconds)

low= fast reaction, high value= slow reaction

Action of stages:

0= cumulative: stage 1 stays on when 2 on comes on

1= single: stage 1 turns off when 2 on comes on

2= digital: stage 1 only, stage 2 only, then stage 1 plus 2

Offset for heating/reverse binary sequences

Offset for cooling/direct binary sequences

Activation of reverse/direct (heat/cool) sequence

OFF= activates based on demand

ON = follows heat/cool state of controller

Delay for heat /cool changeover when L23=OFF

Fixed set point in standby mode

OFF = Standby set point shift applies

ON = In standby mode use minimum set point limit as set point

in heating mode or maximum set point limit in cooling mode

Set point compensation range, the maximum range the set point

is shifted.

0 = Temperature setback: the set point is shifted towards

set point limit

Loading...

Loading...