Testing Procedures Simulated Leak Test - 4 Step Test

8

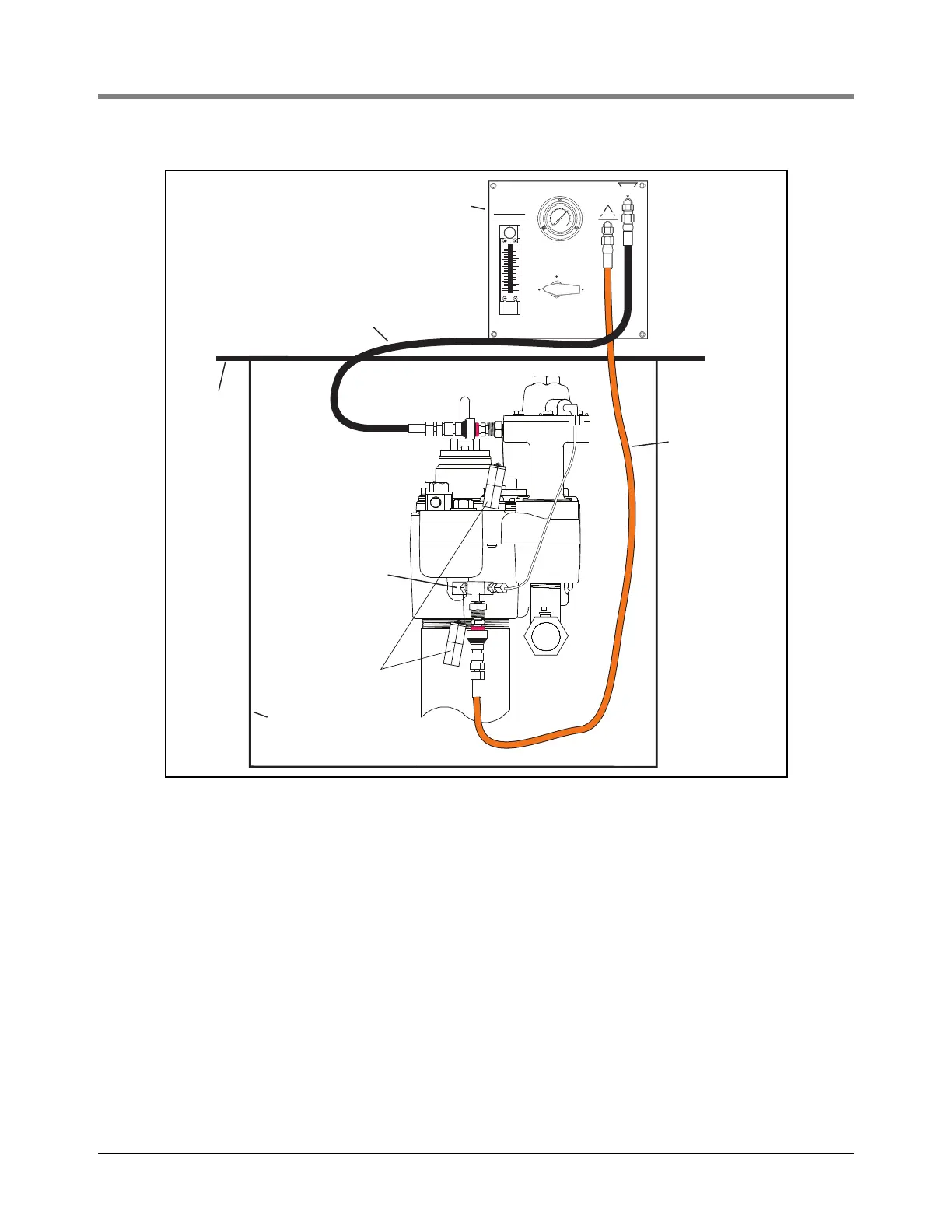

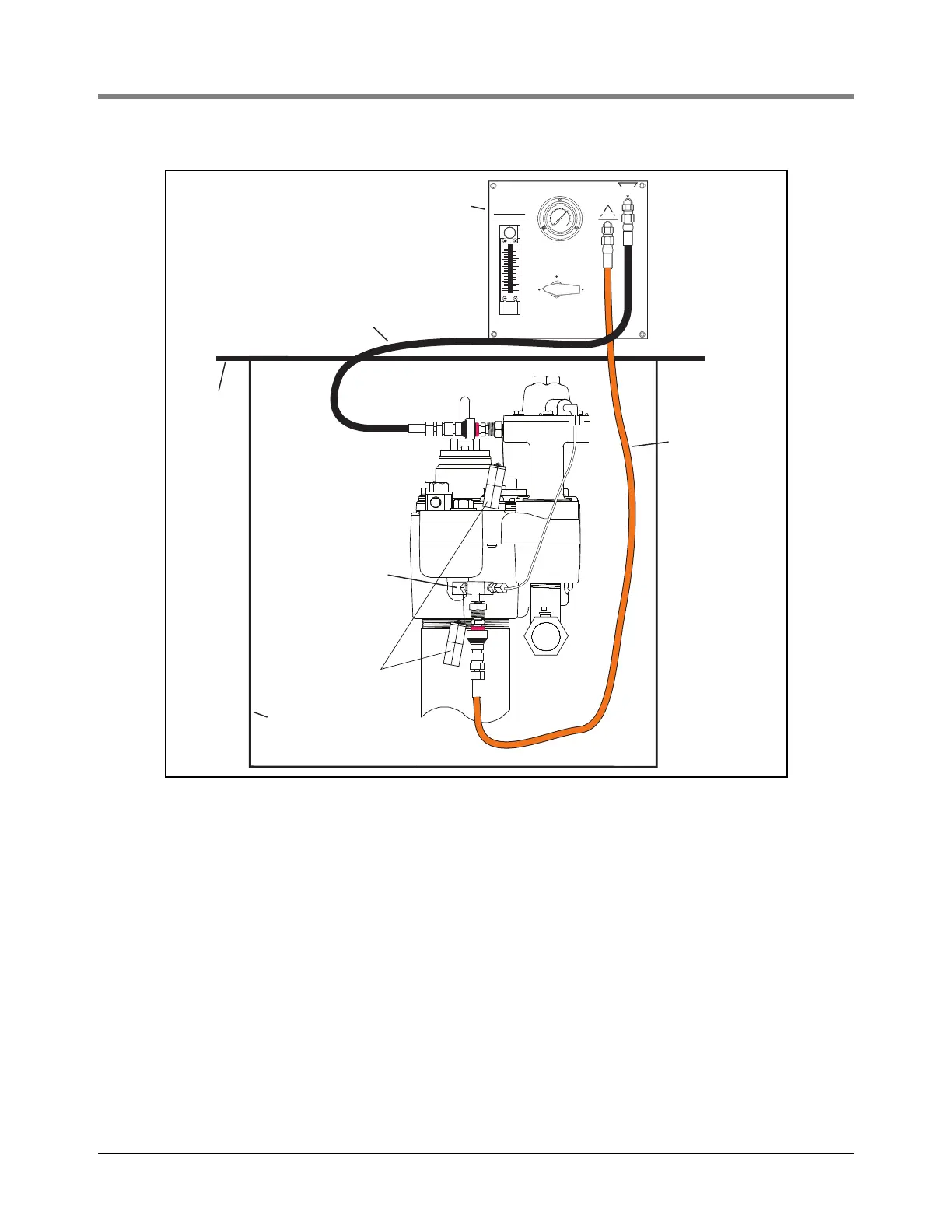

Figure 3. Example FX tester connection to the Red Jacket pump

The FXT will be required for this procedure. The V-R FX2 Series LLD and the Snap Tap Connectors must be

installed before testing can begin. Refer to FX installation instructions 042-106-1.

1.

a. Connect the black hose of the FXT to the Snap Tap Connector at the tank test port of the pump. The black

hose is the path to the tank. Line pressure can be relieved through this path.

b. Connect the orange hose of the FXT to the Snap Tap Connector on the FX2 Series LLD. The orange hose

is the path to the line.

c. Turn FXT’s Selector Valve to ‘Pump/Line Pressure’ position as shown in Figure 4. When the selector valve

is in this position, the FXT is monitoring actual line pressure. As actual line pressure is displayed on the

compound gauge, specifications can be checked.

d. Observe pump operating pressure. This step may be done while dispensing is in progress. Check pump

operation specifications to verify pump pressure output and relief pressure.

e. From Table 1, below, select a leak rate at which to test. The top row of numbers (starting with 3) are the

choices, reflected in gph.

LINE

PRESSURE

3

0

3

0

2

0

20

1

0

1

0

1

0

0

4

0

5

0

6

0

VENT

LEAK

TEST

PRESSURE

RELIEF

SELECTOR VALVE

PUMP/LINE

PRESSURE

LEAK RATE

FLOW METER

VALVE

DO NOT OVER

TIGHTEN VALVE

GPH

25

20

15

10

10

15

20

5

1

00

1

5

GPH

G

A

S

O

L

I

N

E

D

I

E

S

E

L

FX Tester

Grade

Sump

Black Hose

Orange Hose

Tethered

Cap

(Shown) FX2V

FX2DV

272-2.eps

1/4” NPT 45 degree

elbow and tee install

in tank vent port

Loading...

Loading...