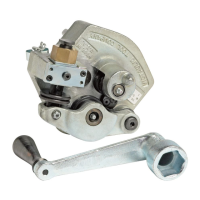

How to keep pipe in grooving rolls of Victaulic Tools?

- SSherry MeyerAug 14, 2025

If the pipe will not stay in grooving rolls of Victaulic Tools, it could be due to incorrect pipe positioning of a long pipe length. Please, refer to the "Long Pipe Lengths" section. Alternatively, the lower roll and pipe might not be rotating clockwise. In that case, flip the switch on the power drive to the opposite rotation position.