21

SERVICE PRECAUTIONS

Air Recharging in Compressor

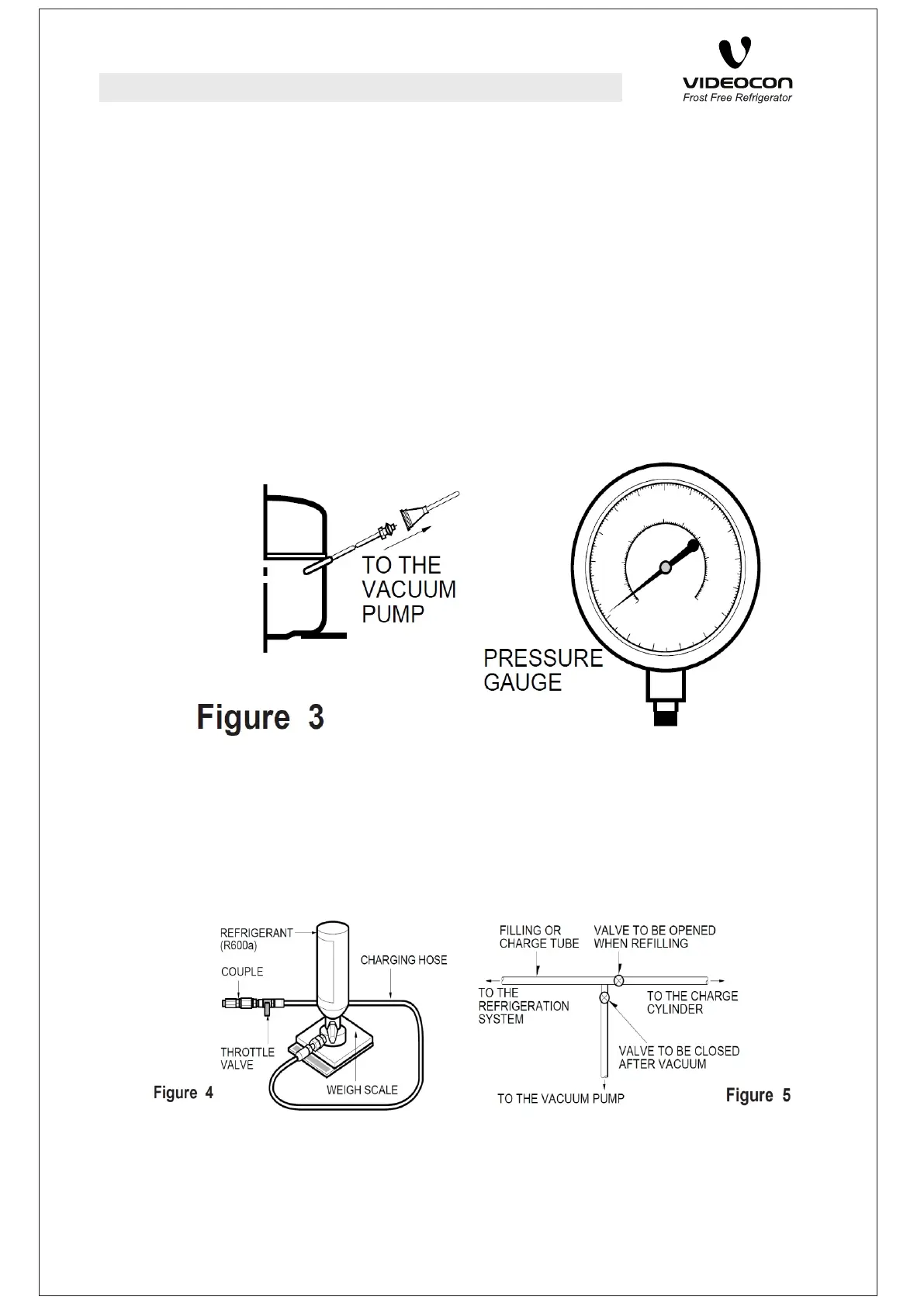

Attach the service tube installed with a Schrader valve (one-way valve) by using

the Lokring (Figure 2). Then, connect the Schrander valve (one-way valve) to the

pump that is connected to the discharging hose leading to the outside. When

discharging the residual refrigerant, repeat 3 cycle that includes 3min of pump

running->pump off->30sec of the compressor running.

After the refrigerant (R600a) is completely discharged, repair any defective parts

and replace the dryer. At any case you must use the LOKRING for connecting or

replacing any part in the cycle (No Fire, No Welding). Connect the Schrader valve

to pump with the coupler. And then turn the pump on for vacuum state (Figure 3).

Let the pump run until the low-pressure gauge indicates the vacuum (gauge

pressure 0, absolute pressure -1atm or -760mmHg). Recommended vacuum time

is 30 min. Charge the N2 gas in order to check for leakage from welding points

and the LOKRING. If leakages are found, repair the defects and repeat the

vacuum process.

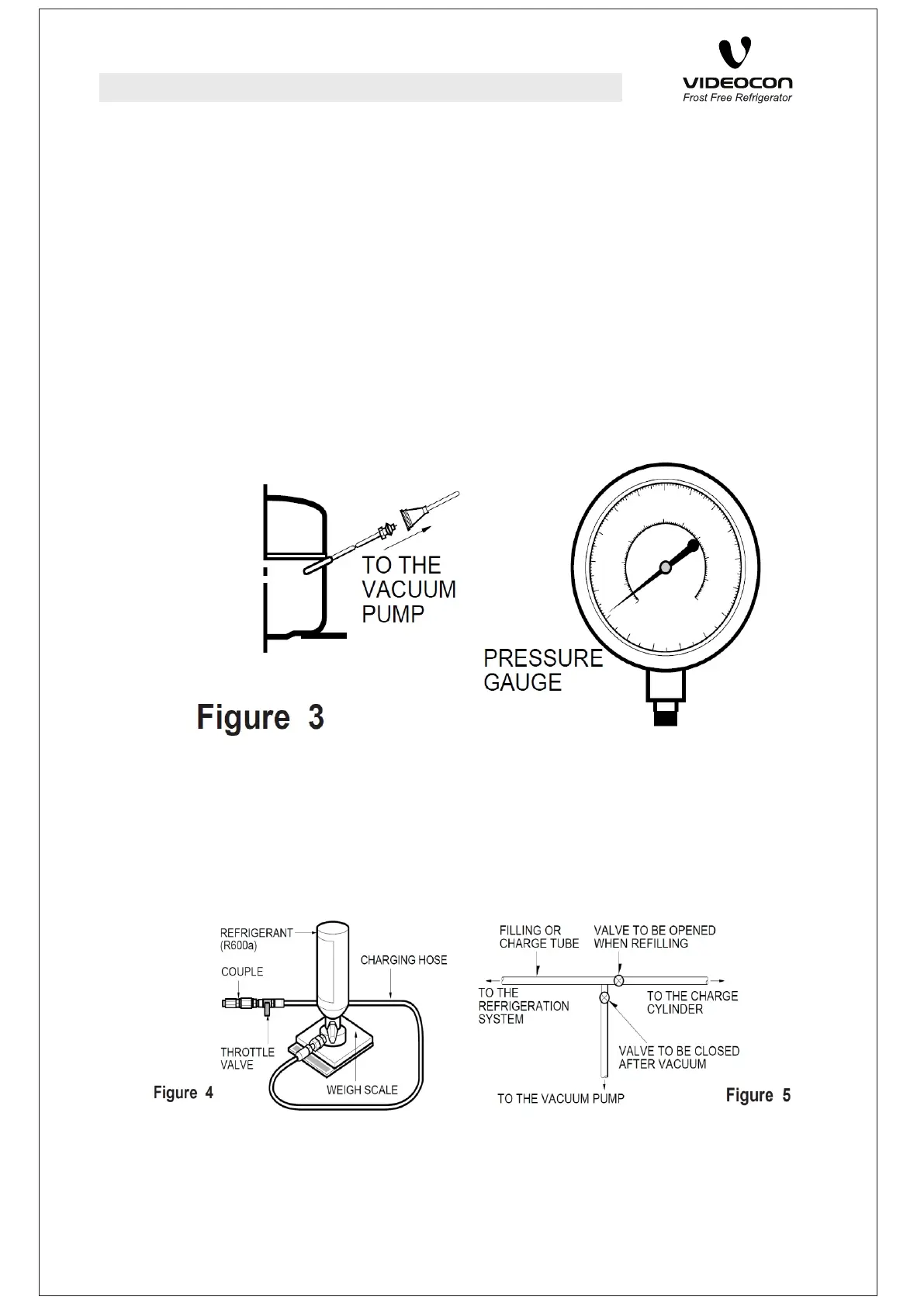

After the system is completely vacuumed, fill it with the refrigerant R600a up to

what has been specified at your refrigerator Name Plate. The amount of refrigerant

(R600a) must be precisely measured within the error of ±2g by an electron scale

(Figure 4).

If you use the manifold connected with both the refrigerant (R600a) cylinder and

the vacuum pump simultaneously, make sure the pump valve is closed (Figure 5).

Loading...

Loading...