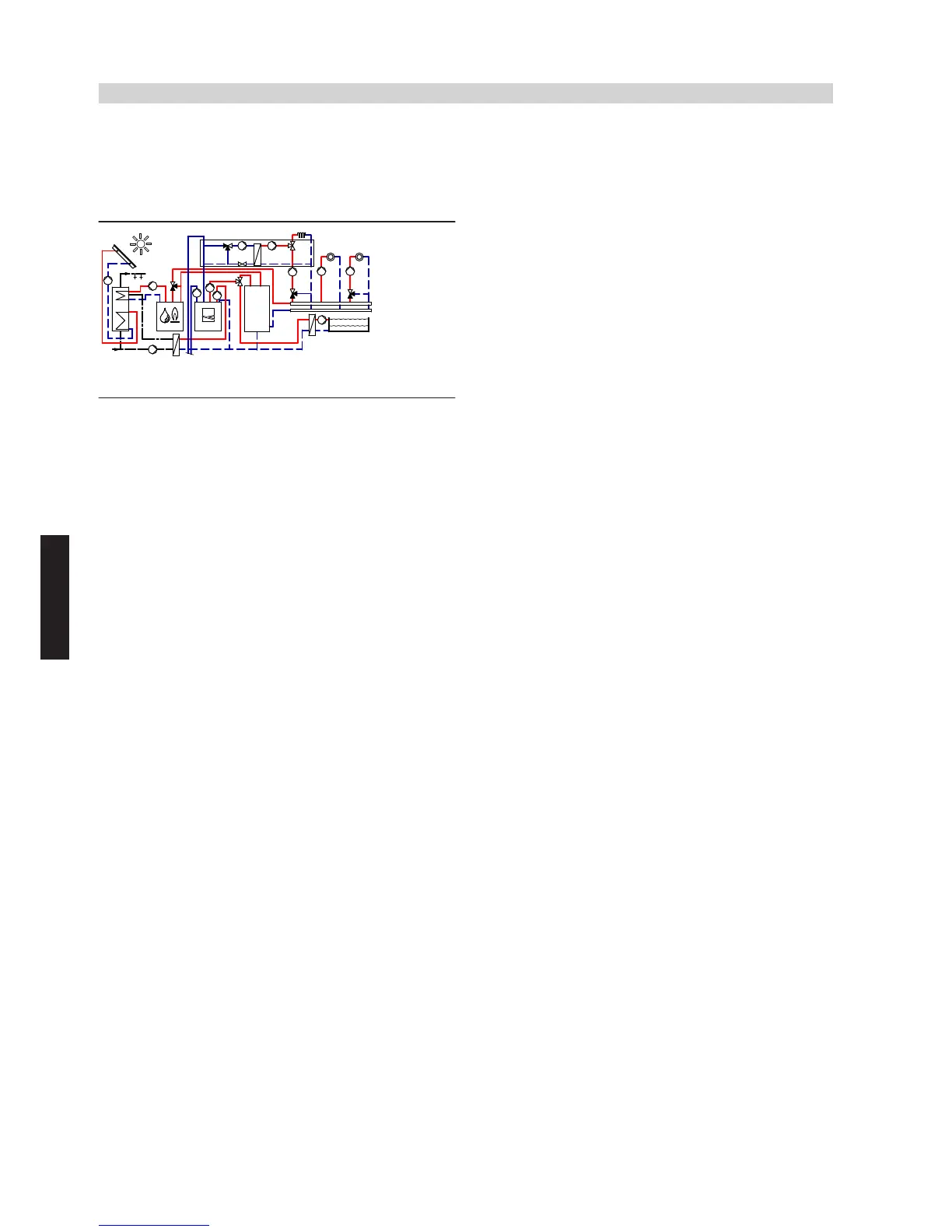

4.4 Vitocal 300-G/350-G with one heating circuit without mixer, two heating circuits with

mixer, DHW heating with solar backup, heating water buffer cylinder, external heat source

(dual mode parallel operation), natural cooling function via NC-Box (with mixer), and

swimming pool

ID: 4605352_1304_03

Application range

Detached houses and apartment buildings with swimming pool, with

up to three different heating circuits and cooling demand. Size DHW

cylinder

eP

in accordance with current standards and requirements.

Main components

■ Vitocal 300-G/350-G, type BW or BWC, up to 17 kW

■ Vitotronic 200, type WO1B

■ DHW cylinder

■ Heating water buffer cylinder

■ NC-Box

■ External heat source with Vitotronic 200, type KO1B, KO2B, KW6B

■ Solar thermal system for DHW heating

■ Swimming pool

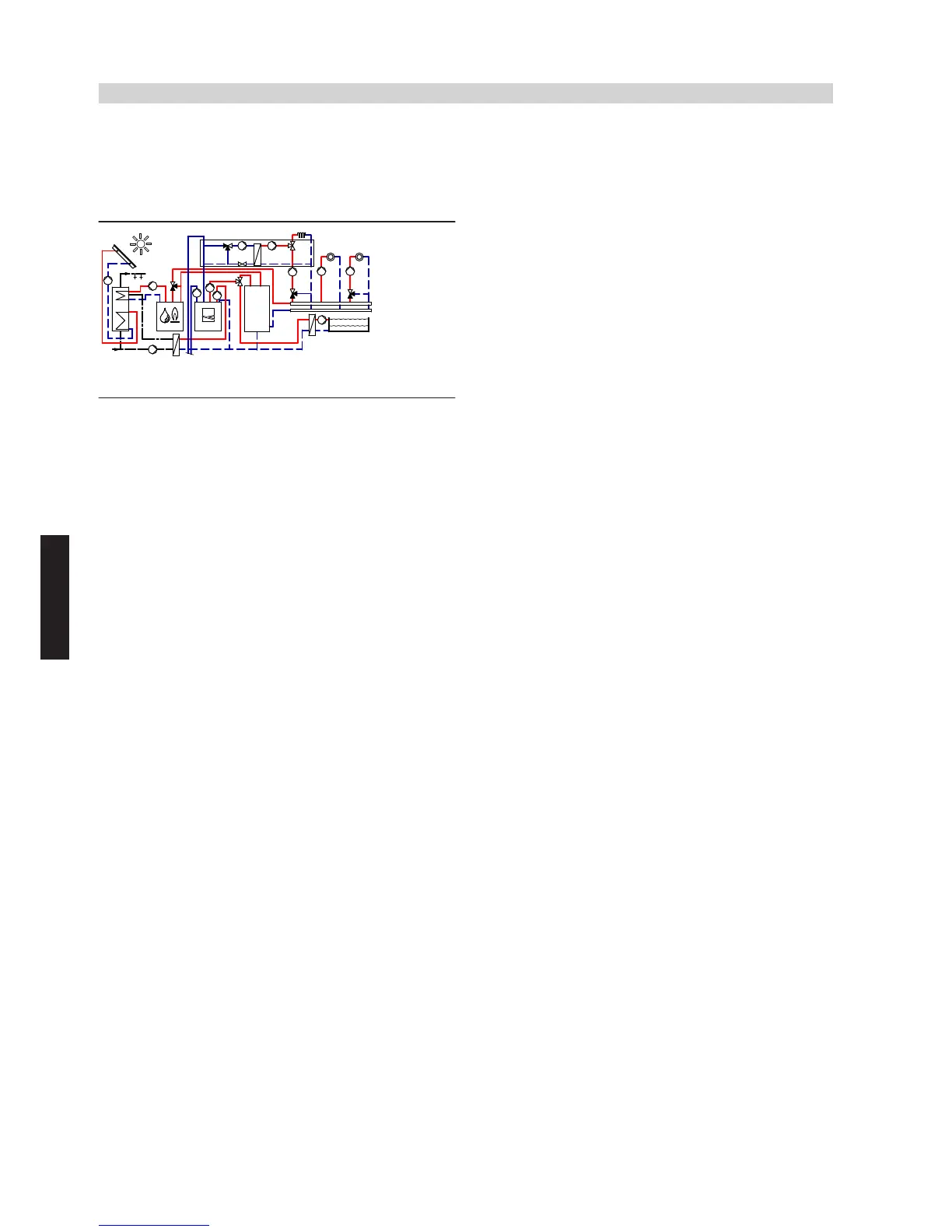

Heating water buffer cylinder

The minimum flow rate of heat pump

1

is safeguarded via heating

water buffer cylinder

tP

and secondary pump

6

. It is possible to use

differential pressure-dependent heating circuit pumps

zU

,

iE

and

oZ

.

Central heating by heat pump

Heat pump

1

and secondary pump

6

start when the actual tem-

perature captured by temperature sensor

tQ

of heating water buffer

cylinder

tP

falls below the set temperature selected at control unit

2

.

Heat pump

1

supplies the heating circuit with heat. Control unit

2

regulates the heating water flow temperature and thereby the heating

circuit. Secondary pump

6

delivers the heating water to heating water

buffer cylinder

tP

. The heat pump with primary pump

5

and secon-

dary pump

6

is stopped when the set temperature at the integral

return temperature sensor is reached. Heating circuit pumps

zU

,

iE

and

oZ

deliver the required water volume to the heating circuits.

To balance the difference in energy between the primary and secon-

dary circuits, operate heating water buffer cylinder

tP

in parallel to the

heating circuits. Any heat not absorbed by the heating circuits is stored

in heating water buffer cylinder

tP

. In addition, heat pump

1

achieves

long runtimes.

During the power-OFF period, the heating circuits will be supplied with

heat from heating water buffer cylinder

tP

.

DHW heating by heat pump

In the delivered condition, DHW heating by heat pump

1

is given

priority over the heating circuit and should ideally take place during the

night.

The heat demand is issued via upper cylinder temperature sensor

eQ

and control unit

2

, which controls the circulation pump for cylinder

heating

7

, cylinder loading pump

eZ

and motorised 2-way valve

eE

.

Heat pump

1

raises the flow temperature to the value required for

DHW heating.

The cylinder temperature can be raised above 60 °C with external heat

source

wP

.

DHW heating with solar backup

Control unit

2

can be connected via KM BUS distributor

qQ

to a

Vitosolic 100, type SD1

rQ

to achieve DHW heating with solar

backup.

Circulation pump in Solar-Divicon

rP

starts and DHW cylinder

eP

is

heated up when the temperature differential between collector tem-

perature sensor

rW

and cylinder temperature sensor

rR

exceeds the

set value.

The solar thermal system heats the cylinder to the set value selected

in the Vitosolic 100, type SD1

rQ

.

Central heating with an external heat source

A demand signal is issued to external heat source

wP

if the heat pump

cannot maintain the required flow temperature (captured by flow tem-

perature sensor

wE

) and if the outside temperature is lower than the

dual mode temperature of the external heat source. The external heat

source starts; mixer

wW

initially remains closed towards the heating

circuit. Mixer

wW

opens towards the heating circuit only when the

required flow temperature has been reached at boiler water tempera-

ture sensor

wU

. Mixer

wW

closes towards the heating circuit when the

required flow temperature has been achieved. External heat source

wP

is shut down when the flow temperature (captured by

wE

), with

mixer

wW

closed towards the heating circuit, no longer falls below an

adjustable threshold for a given period (i.e. there is either no longer

any heat demand or heat pump

1

is supplying adequate heat).

Note

The system example is only applicable in conjunction with modulating

boilers without lower temperature limit.

Match the heating curve of the external heat source to the heating

curve of the heating circuit with the highest flow temperature. Depend-

ing on the system scope and layout, we recommend that these are

offset upwards in parallel.

Natural cooling function

The building can be cooled with heat pump control unit

2

in conjunc-

tion with NC-Box

uP

(accessories). The natural cooling function is

enabled by control unit

2

as soon as the outside or room temperature

(cooling limit temperature) that can be selected at control unit

2

is

exceeded. Circulation pumps

uQ

and

uW

in NC-Box

uP

start and 3-

way diverter valve

zI

switches to cooling. Heat is now extracted from

the room via underfloor heating circuit

zP

and transferred to the brine

circuit via the plate heat exchanger in NC-Box

uP

. The brine circuit

transfers the heat to the ground. DHW can be heated by heat

pump

1

whilst cooling mode is operational.

Swimming pool heating

Swimming pool heating is produced hydraulically via the changeover

of 3-way diverter valve

q-R

. If the temperature falls below the value

set at the thermostat for swimming pool temperature control

q-Q

, a

demand signal is sent to control unit

2

.

In the delivered condition, the swimming pool heating is supplied with

priority 3. In the selected priority, DHW heating is operated with priority

1 and central heating with priority 2. The swimming pool water is

heated to the set value selected at the thermostat for swimming pool

temperature control

q-Q

.

Vitocal 300-G/350-G

(cont.)

86

VIESMANN

System examples

4

5822 472 GB

Loading...

Loading...