Gasifying boiler Vigas

14.5 SERVICE BOILER CLEANING

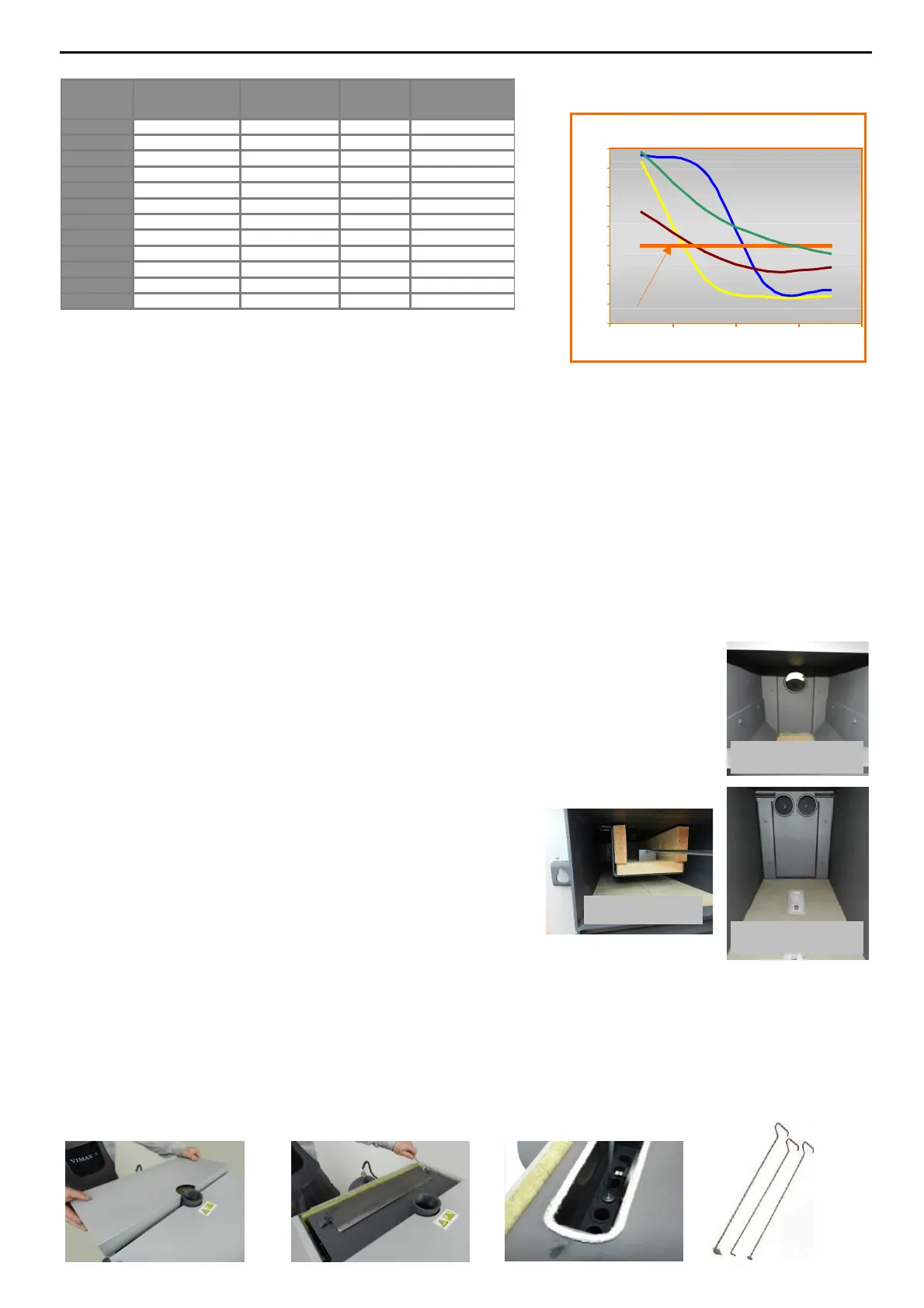

Wood characteristic table

Wood

Fuel efficiency

[MJ/kg]

20% humidity

Fuel efficiency

[MJ/kg]

25% humidity

Hardness *

weight [kg/m

3

]

25% humidity

Poplar 12,9 12,3 1 530

Fir 15,9 14,0 1 575

Spurce 15,3 13,1 1 575

Willow 16,9 12,8 1 665

Pine 18,4 13,6 1 680

Alder 16,7 12,9 2 640

Birch 15 13,5 2 780

Maple 15 13,6 4 660

Beech 15,5 12,5 4 865

Ashen 15,7 12,7 4 865

Locust 16,3 12,7 4 930

Oak 15,9 13,2 4,5 840

[kg/m

3

] = [kg/fm], fm – fullmeter, * (1 very soft...5 very hard)

24

Important attention !!!

Use only recommended fuel.

It is advise not to overload the boiler with fuel when in temporary period, boiler tar can be decresed.

When adding fuel, do not let it remain between flange and chimney flap, which can cause inaccuarte flap

closure.

It is important to lay fuel properly, so it will not stop upper door to close. Forced closing may damage door

concrete inwall.

We recommend to supervise boiler according to operating conditions only by person over 18 years old.

Gasification chamber cleaning

It is necessary to remove tar from gasification chamber once per week. We

recommend to burn it with upper door and chimney flap open. If there is extra ash

which did not fall through the nozzle (9)pic.3 into fireclay combustion chamber, this

should be removed from time to time. Fuel bunker will be increased to original size

and primary air flow through nozzle will be increased.

During optimal wood burning and keeping minimum temperature of the water reverse at 60 °C is gasifying

chamber and exchanger sooted only slightly. By using dampy wood, steam may condense on the walls of

the combustion chamber, which creates tar on the surface.

Exchanger cleaning

It is necessary to clean exchanger pipes once per month using fire rake (round plate).

Recommendation: If you do not clean exchanger on time and it is clogged with tar, do not use dissolvent.

The boiler must be cleaned while hot! Heat boiler through open upper door and chimney flap approx. to

80°C (without fan).Then close flap and door. Carefully (use gloves) open exchanger cover. Clean clogged

pipes with relevant accessories. After cleaning, close exchanger cover and let the boiler burn / gasify /

approx. 5 hours at maximum performance, in order to get rid of remaining tar. Try to avoid this condition in

the future.

Warning: During cleaning must be boiler room very well ventilated!

Combustion chamber cleaning

Sweep ash and dust that fell into combustion chamber with

a scraper. It is recommended to sweep ash, which settles in

combustion chamber once in 3 - 5 days.

Gasifying chamber

VIGAS 25,40

Gasifying chamber

VIGAS 60,80,100

Combustion

chamber

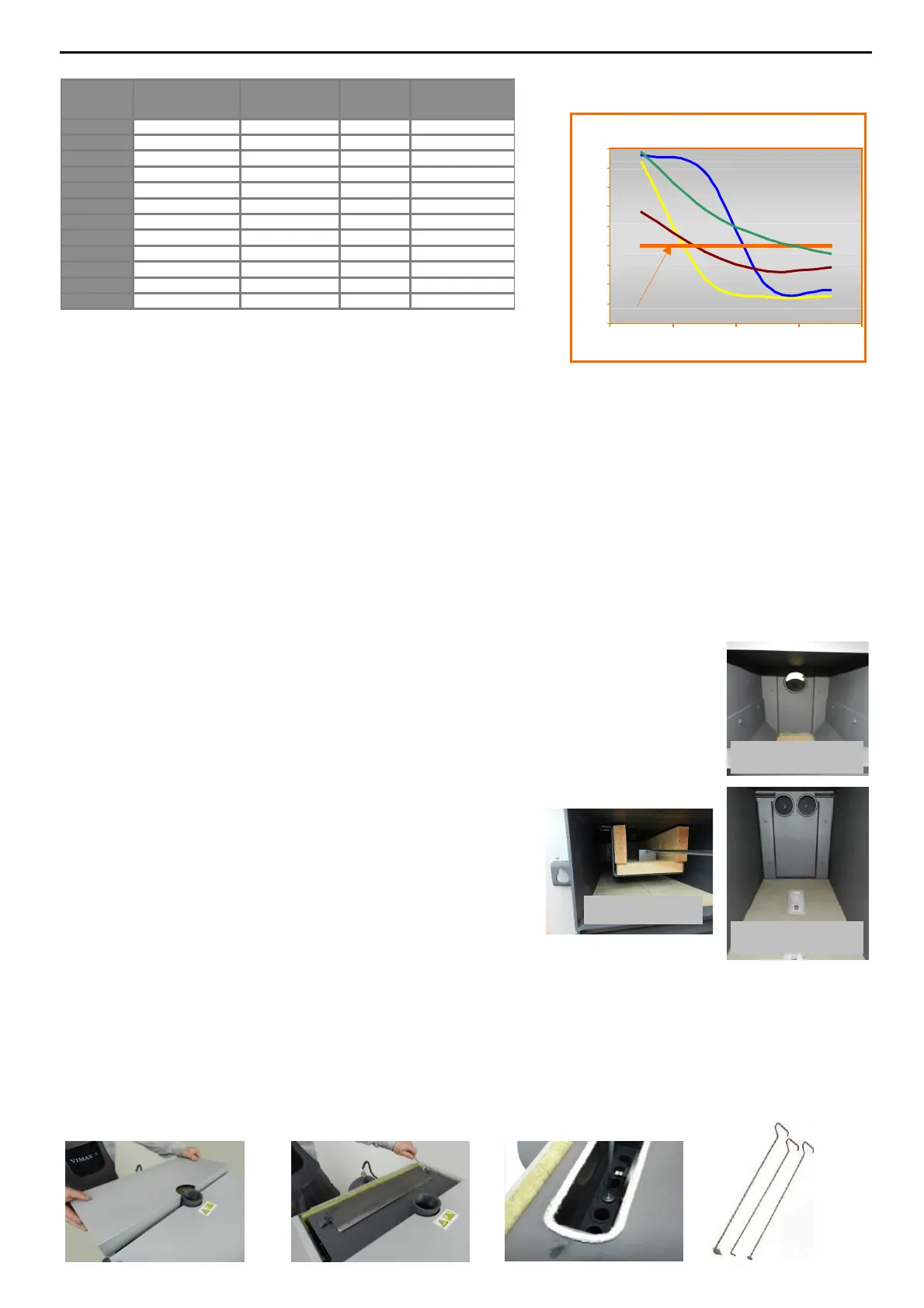

Humidity dependence period

( wood cuts)

Fir

SPURCE

Beech

Recommended humidity 20%

OAK

12

14

16

18

20

22

24

26

28

30

6 12 18 24

Number of months after cutting

humidity [%]

Loading...

Loading...