TECHNICAL DATA

Page 3 of 4

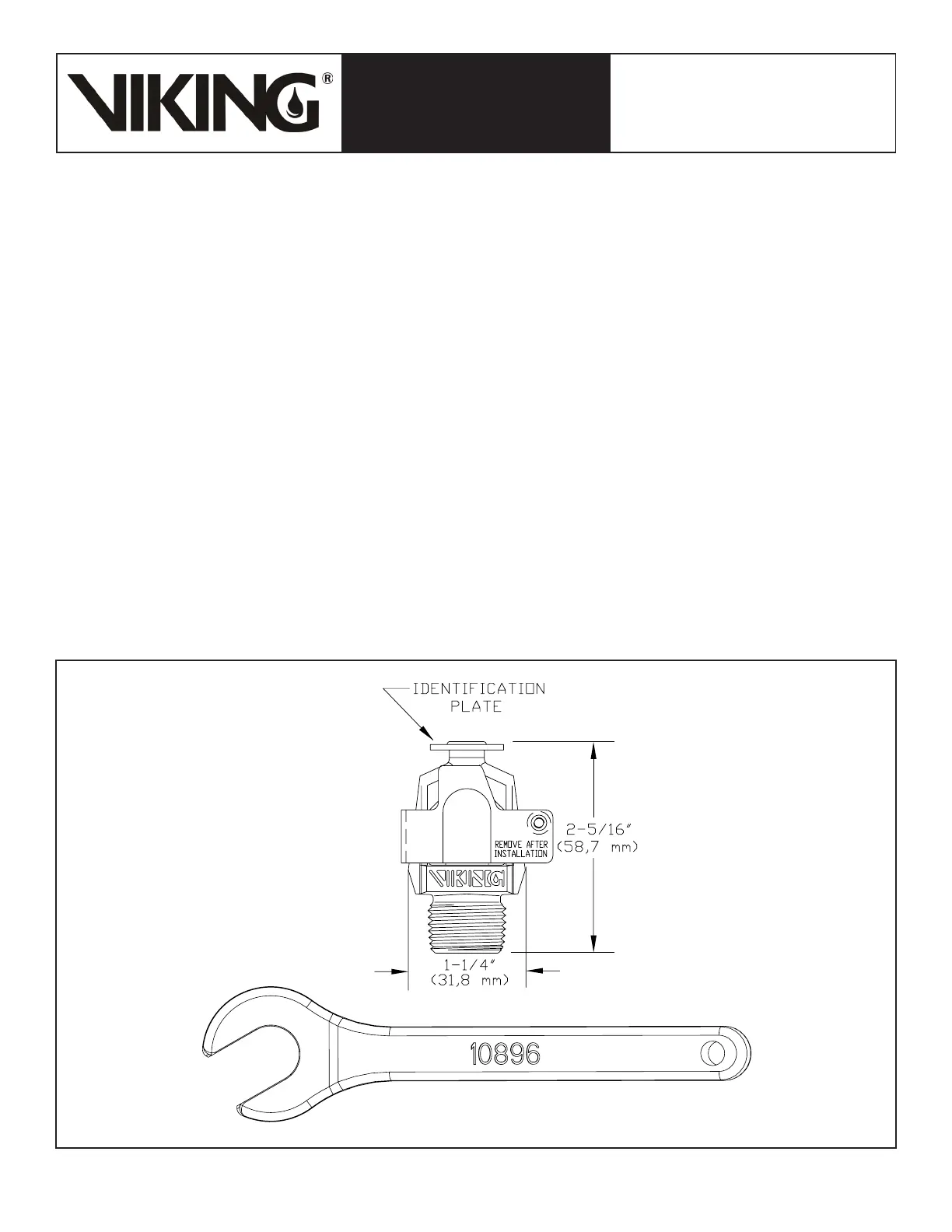

MICROFAST HP

FIXED TEMPERATURE

RELEASE VK800

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Form No. F_051091 18.10.25 P65

1. The Viking MicrofastHP® Fixed Temperature Release is to be installed in accordance with the latest edition of Viking techni-

cal data, and the applicable installation standards such as the National Fire Protection Association 13, Factory Mutual Loss

Prevention Guides, Loss Prevention Council or Assemblee Pleniere, Verband der Sachversicherer or other similar organizations,

and also with provisions of governmental codes and ordinances. Fixed temperature releases are often used on systems in special

applications. It is usually necessary to obtain specic approval on each individual installation.

2. The Viking MicrofastHP® Fixed Temperature Release must be installed after the piping is in place to prevent mechanical dam-

age. Before installation, be sure the release has the appropriate temperature rating. Keep releases with glass bulbs contained

within the protective shields during installation and testing, and any time the release is shipped or handled. Apply a small

amount of pipe-joint compound to the male threads only, taking care not to allow a build-up of compound inside the orifice. NOTE:

Releases with glass bulbs must be contained within the protective shields when applying pipe-joint compound or tape. Install

the fixed temperature release on the piping using the special wrench only (Part No. 10896), while taking care not to damage

the operating parts of the fixed temperature release. DO NOT use the identification plate to start or thread the fixed temperature

release into a fitting.

3. Fixed temperature releases must be handled with care. They must be stored in a cool, dry place in their original container. Never

install fixed temperature releases that have been dropped or damaged in any way. Never install any glass-bulb style fixed tem-

perature release if the bulb is cracked or if there is a loss of liquid from the bulb. If a glass bulb lacks the appropriate amount of

fluid, it should be set aside and returned to Viking (or an authorized Viking distributor) for analysis as soon as possible. If the fixed

temperature release is not returned to Viking, it should be destroyed immediately. Never install xed temperature releases that

have been exposed to temperatures in excess of the maximum ambient temperature allowed. Such devices should be destroyed

immediately.

4. Corrosion-resistant fixed temperature releases must be installed when subject to corrosive atmospheres. Use only fixed tem-

perature releases with finishes listed for corrosive environments when subject to corrosive atmospheres. When installing corro-

sion-resistant fixed temperature releases, care must be taken not to damage the corrosion-resistant coating. Use only the special

wrench (Part No. 10896) designed for installing coated Viking sprinklers and Viking fixed temperature releases. (Any other wrench

may damage the unit).

5. Viking MicrofastHP® Fixed Temperature Releases are listed for installation in any position. However, when installing them on

release piping subject to freezing, install them in the upright position only. Hydraulic release lines must be installed in heated

Figure 1 - Standard Sprinkler Wrench

Loading...

Loading...