10

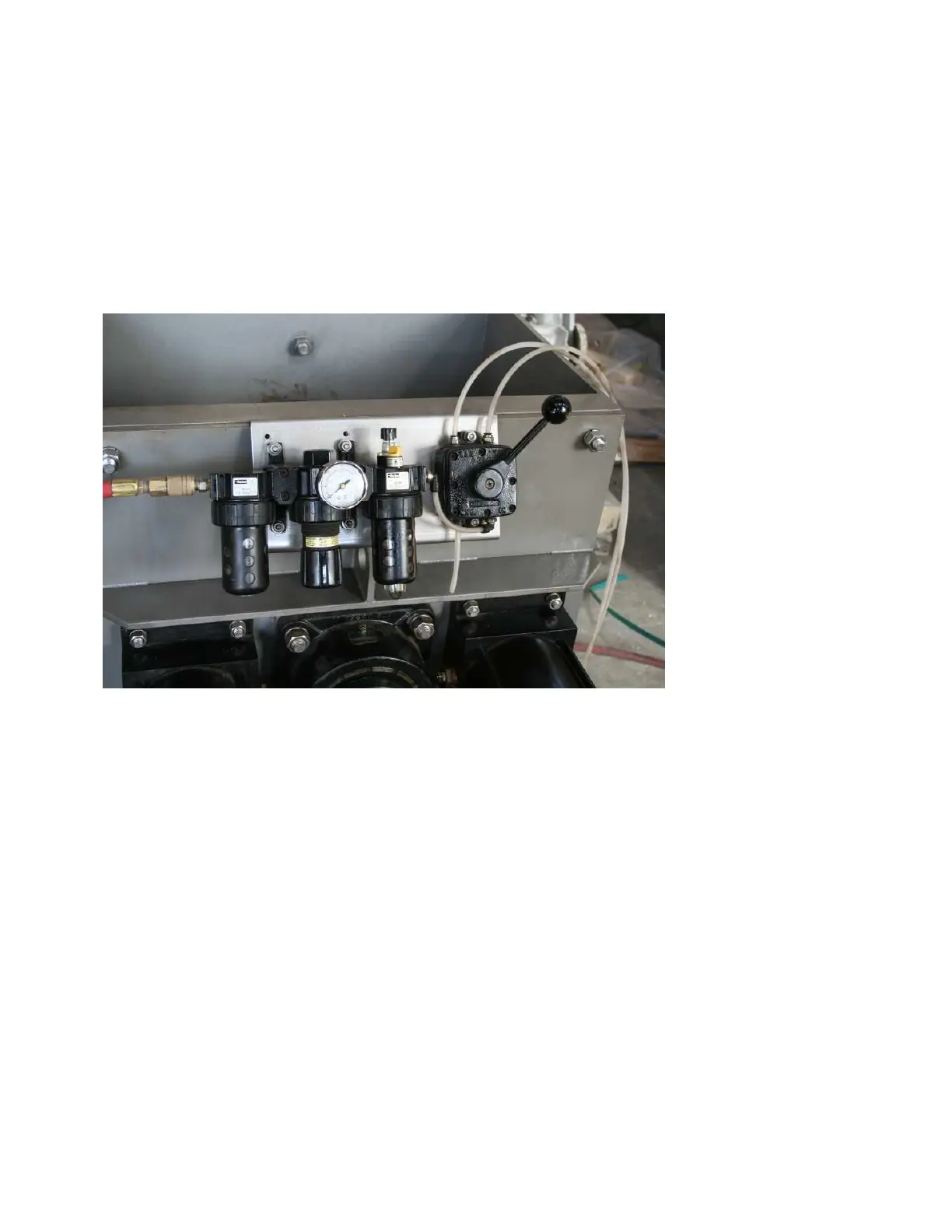

Once material is going through the press, set the 4-way valve so that the discharge

cone goes shut in the "in" or closed position. Start with a low air pressure, working

your way up until the desired performance is obtained.

The neutral position of the Parker valve is used only in testing. If left in the neutral

position, the cone will not move unless it is pushed open by press cake. If, later, the flow

of press cake is diminished, the cone will remain in the position to which it was pushed,

and purging can occur.

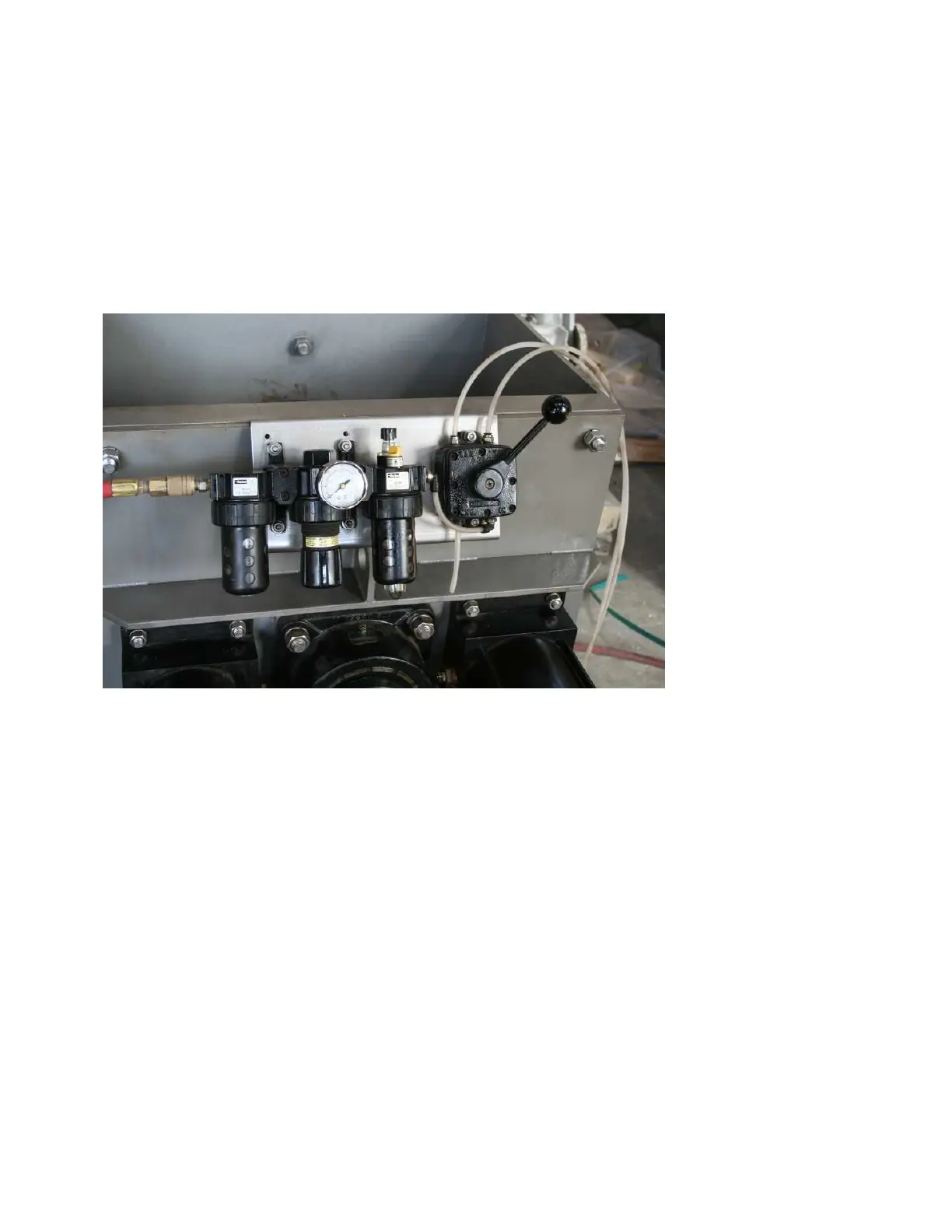

FRL AIR REGULATOR WITH 4-WAY REVERSING VALVE

DISCHARGE CONE

The principal adjustment of the press is made with the discharge cone. The cone is the

component at the cake discharge end of the press that acts as a door or stopper plug to

restrict material from leaving the press. The more pressure exerted by the discharge

cone, the drier the cake material will be leaving the press. Also, the motor amps can be

expected to increase with added pressure, and throughput may decrease.

The discharge cone is moved in (actuated) either by an air cylinder or, rarely, by

weights. Typical air cylinder pressures are in the range of 30 to 60 psi. Some

materials will press only in a low range, say 10 to 20 psi. Other materials may

press best with a pressure of 60 to 100 psi. Air consumption is minimal in all

models, 1 to 2 cfm.

Loading...

Loading...