16

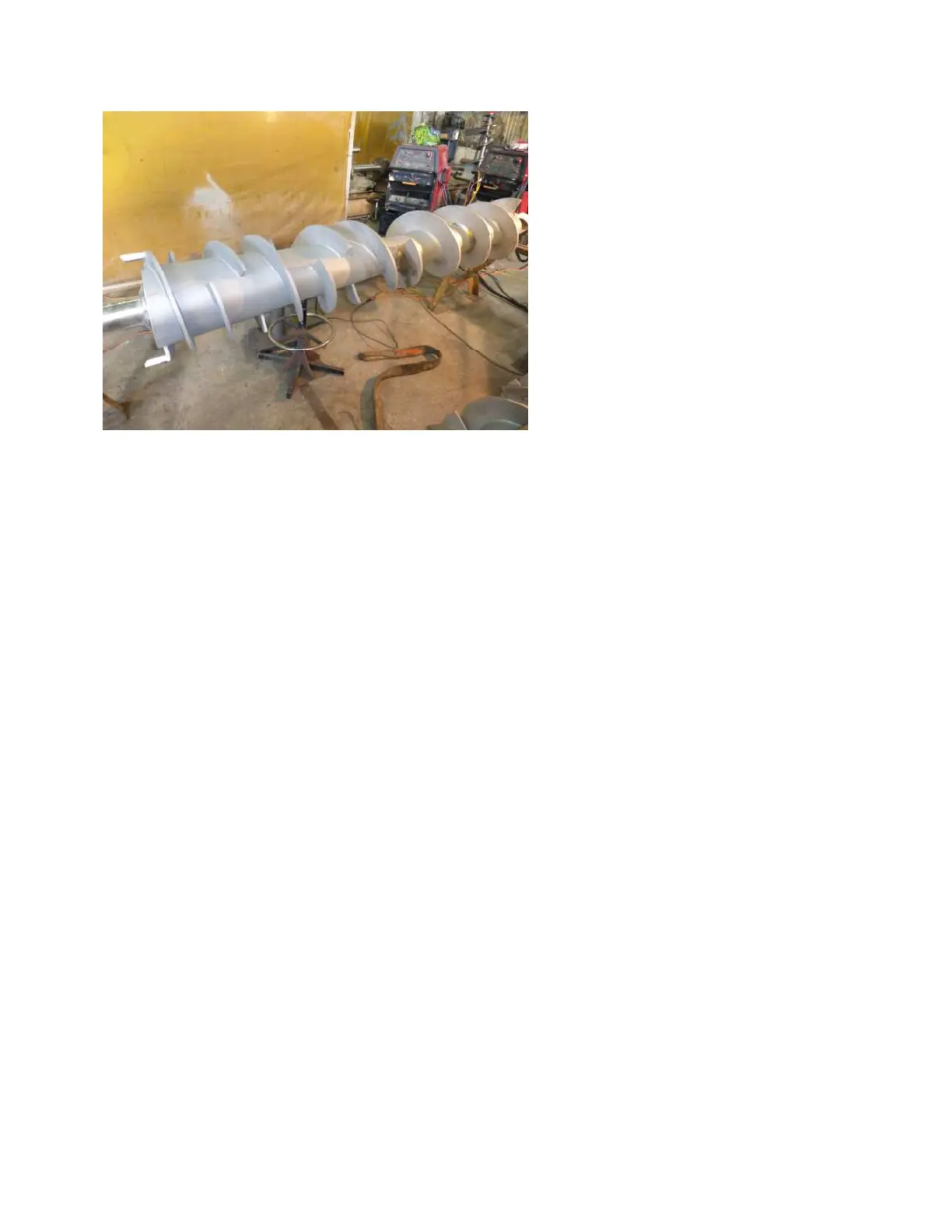

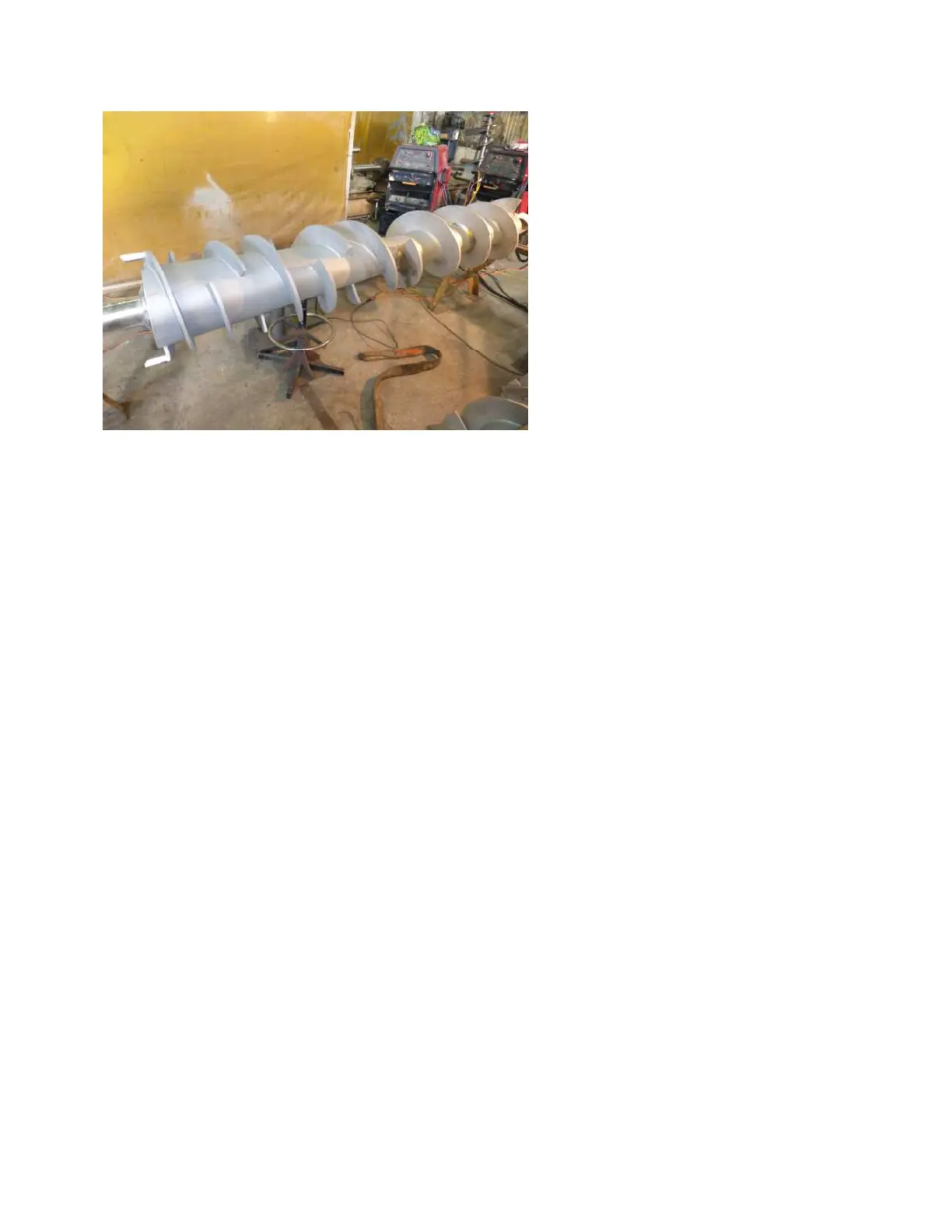

SCREW WITH TAPERED SHAFT

Force-feeding (supercharging) the press and applying a vacuum to the outside of

the screen are two additional methods which may achieve compression. These

two are used infrequently because the performance results are uncertain.

PRESS SPEED (RPM)

In general, the slower the screw speed, the greater the dewatering. Longer

residence time in the screened area results from lower screw speed, which allows

time for more thorough dewatering. Unfortunately, it also goes with reduced

throughput capacity.

Screw press speed (rpm) can be changed by using a Variable Frequency Drive (VFD).

Alternatively, the drive motor can be switched to a different pole motor (900, 1200, or

3600 versus the standard 1800 rpm). Most modern motors are good for permanent 120

Hertz operation; they are always good for a test at this high speed.

Higher speed can result in premature gearbox failure. Switching to synthetic oil, replacing

the normal mineral oil, is recommended. Consult the factory for assistance.

A small change in screw speed, like 15%, will generally not result in a measurable change

in performance of the press.

Low screw speeds are used for cooker crumb, potato peel, many sludges, and low

freeness materials in general.

It has become normal for a variable speed drive (frequency inverter VFD) to be

used with Vincent presses.

Loading...

Loading...