VESDA

®

Refrigerated Storage Design Guide

Offset clips are preferable since they attach to the ceiling via an adhesive pad and, if required, can

be screwed on to the ceiling. The design of offset clips also allows easy movement of the pipes

during expansion or contraction.

To further minimise the possibility of pipe disconnections, pipe mounting clips MUST not be

positioned next to pipe joiners. Clips MUST also be more than 300 mm from the ends of the pipes

so that a pipe contraction will not cause its end caps to be forced off.

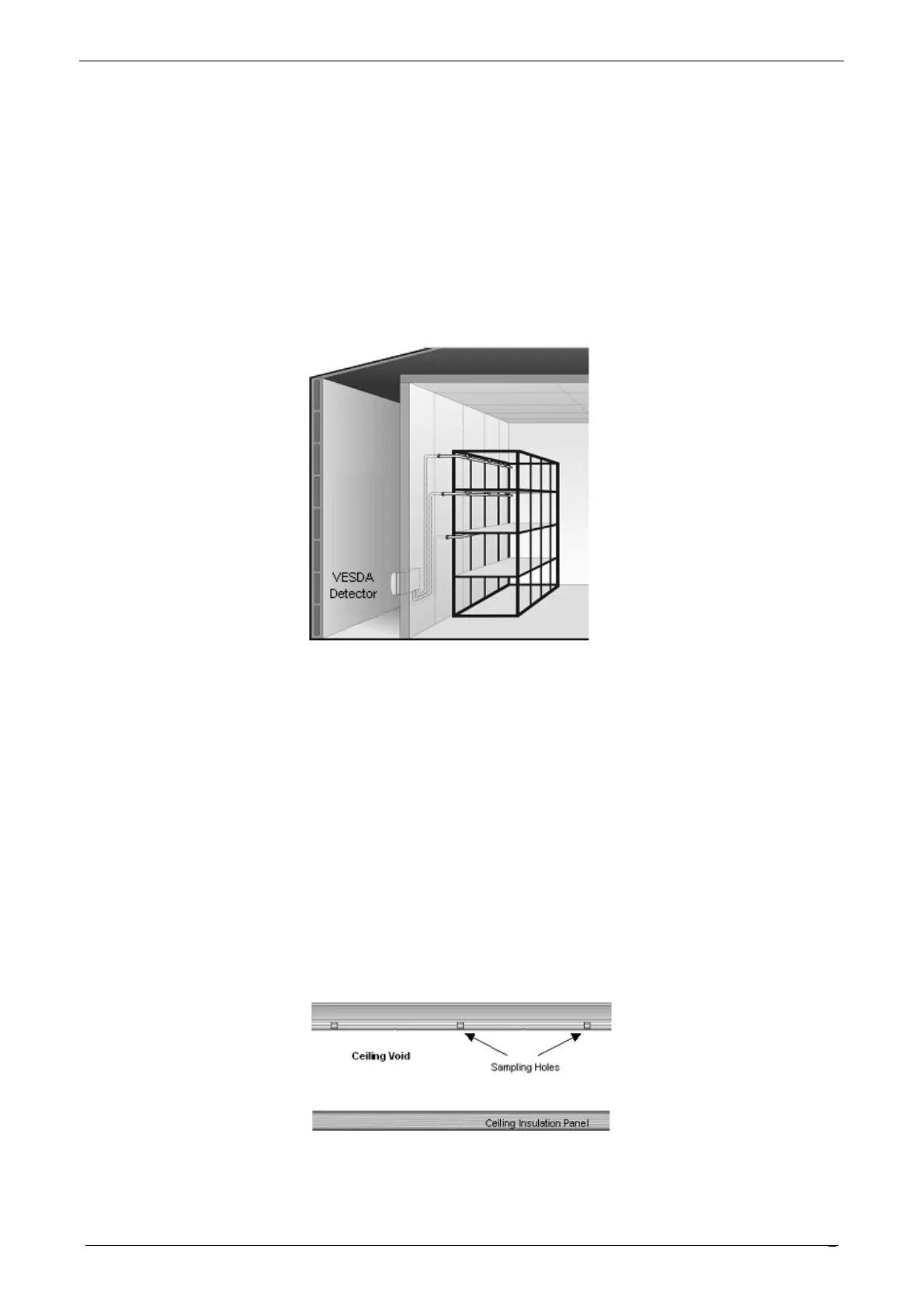

3.6 In-rack Protection

In most cases, placing a VESDA pipe network on the ceiling is all that is needed. However, sample

pipes can also be located along the racks used for storage in the refrigerated area as shown below

(Figure 6).

Figure 6 – Example of in-rack air sampling.

Wherever possible, the in-rack sample pipe should enter the protected area through the wall at the

height that the pipe will be positioned in the rack.

Note: Capillary air sampling is not recommended for in-rack sampling.

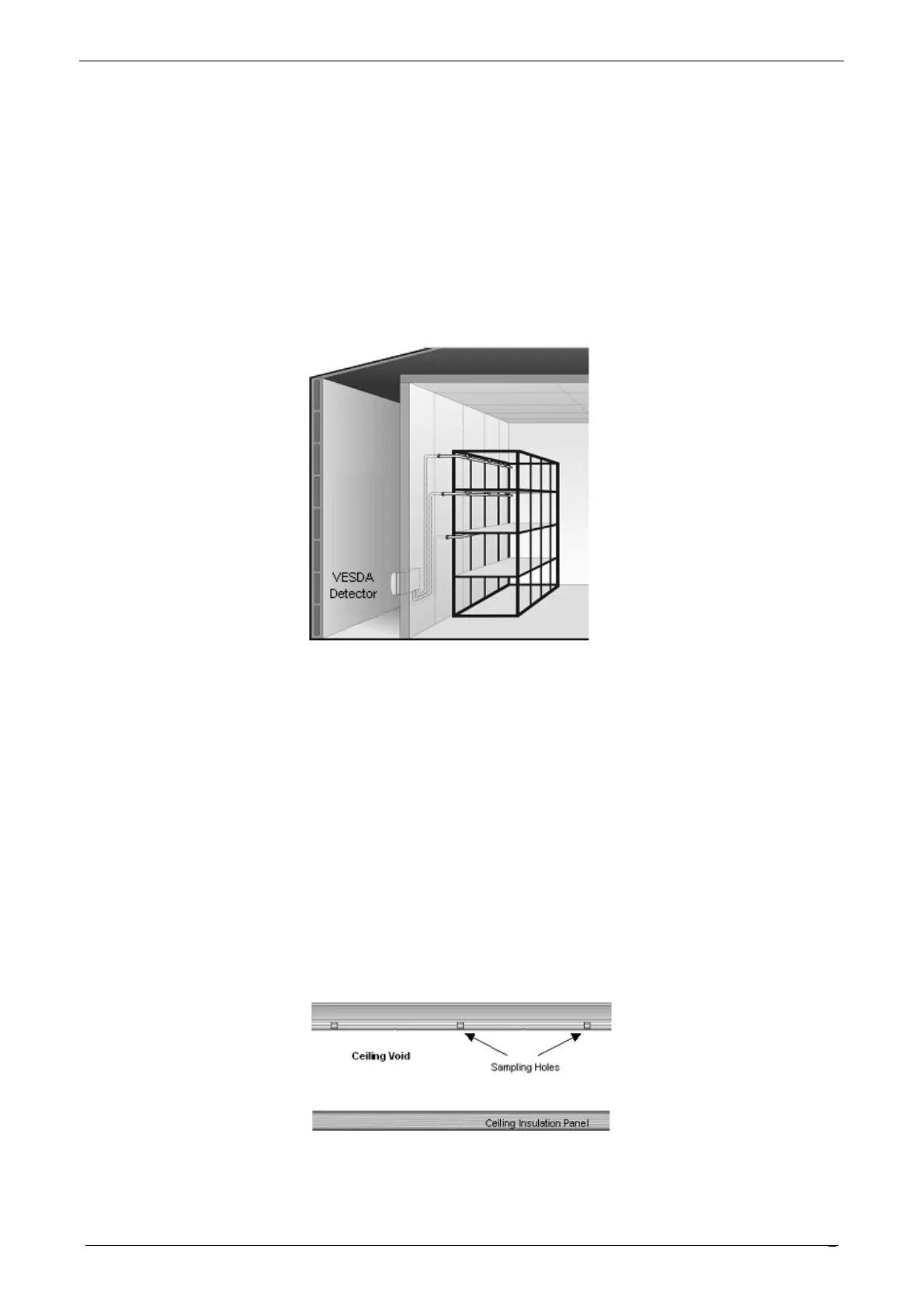

3.7 Ceiling Void Protection

Very early smoke detection is essential due to the high incipient fire risk presented by the electrical

cabling and refrigeration control equipment normally housed in the ceiling void. Some local codes

and standards specify that ceiling void protection must be a component of the fire protection

system.

The sample hole spacing is determined, with reference to local codes and standards, according to

the grid presented earlier (Figure 1) and is shown below (Figure 7).

Figure 7 – Example of ceiling void air sampling.

9

Loading...

Loading...