32

Useful Tips

Useful Tips

for trouble-free operation

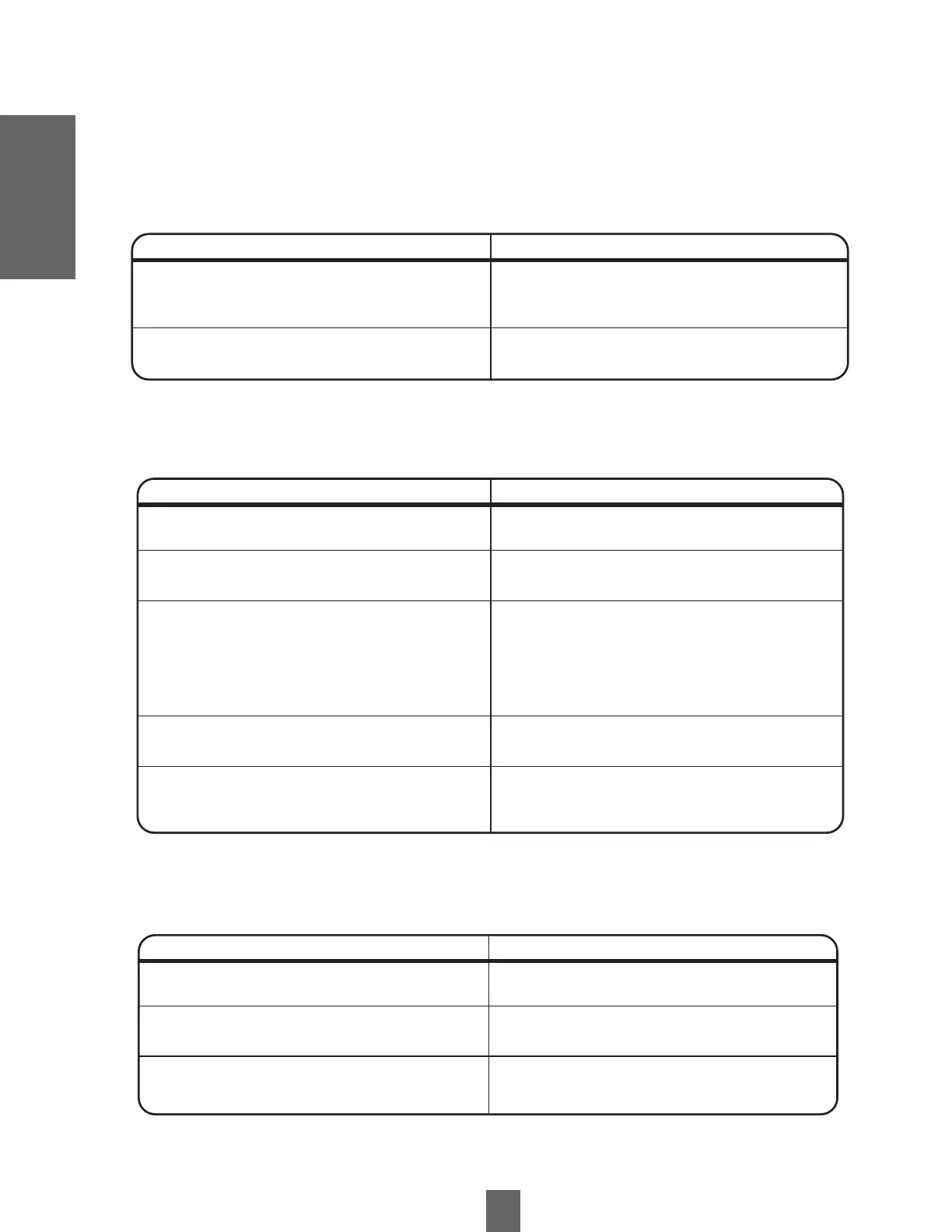

9.3 Pump Overloads Motor

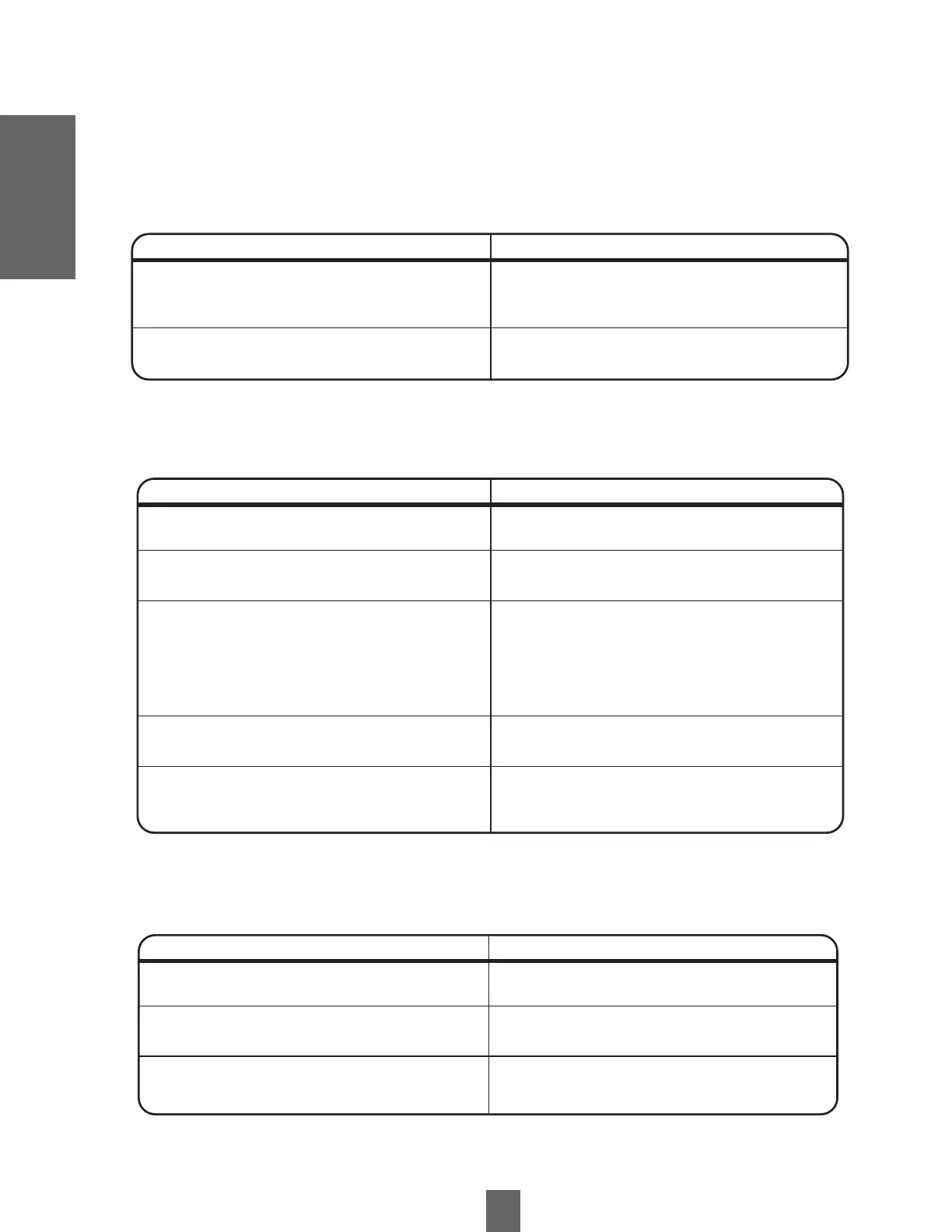

9.4 Abnormal Vibrations of Pumping Equipment

Possible Causes Solutions

1.- The pumped liquid has a viscosity or density

different from that for which the pump was

selected.

· Check and consult the

manufacturer.

2.- T

here are mechanical defects (moving parts

rubbing against fixed parts).

· Check and consider a pump repair.

1.- The pump is not primed.

Possible Causes

Solutions

2.- Air enters the suction pipe.

· Check and complete the filling of the system with

liquid.

· Check and repair damaged ducts and

defective joints.

3.- The suction lift is too high (insufficient NPSH).

· Check that NPSHavailable > NPSHrequired

· Check suction geometric height.

· Check head losses in the suction pipe (partially

closed valve, foreign bodies).

4.

- The impeller is partially clogged causing

unbalance.

· Check and unclog obstructions.

· Check that the bearings are not damaged.

5.- There are mechanical problems, such as bent

shaft, seized parts.

· Check and consider repair.

9.5 Pump Breaks Down After Start-up

Possible Causes

Solutions

1.- Leaks in the suction line.

· Check and repair damaged ducts and

defective joints.

2.- The suction height is too high.

· Check suction height and consult the

manufacturer.

3.- The foot valve or pipe is not sufficiently

submerged.

· Check and submerge as necessary.

Loading...

Loading...