Do you have a question about the Volvo Penta D4-300A and is the answer not in the manual?

Explanation of DANGER, WARNING, CAUTION, IMPORTANT, and NOTICE symbols used in the manual.

Steps to safely stop the engine before performing maintenance.

Checks to perform before starting the engine, including protective parts and air cleaner.

Detailed hazards of fuel, lubricants, non-original parts, batteries, and start spray.

How to maneuver the boat using the joystick for forward, aft, and lateral movements.

Checks for oil, coolant, sea cock, fuel cock, and main switch before starting.

Warning against using start spray due to explosion risk.

Procedure for starting the engine using the ignition switch.

Procedure for starting the engine using the starter button.

Checking instruments and warming the engine before full power use.

Warning about serious injury from rotating propellers and safety checks.

Responding to alarms and messages shown on the information display.

Methods for stopping the engine using the key or stop button.

Procedure for stopping the engine using the ignition key.

Procedure for stopping the engine using the starter button.

Responding to system malfunctions, messages, and buzzer warnings.

Interpreting messages about fault causes and tasks, and how malfunctions affect the engine.

List of messages, descriptions, and recommended actions for system malfunctions.

Safety instructions and procedure for jump-starting the engine.

Description of electronically shifted reverse gear for manual shifting.

Steps to manually engage gears by disconnecting solenoid valve wiring.

Steps to manually engage the drive using a screwdriver or tool.

Warning about fire hazards from fuel, oil, and grease accumulation.

Warning about investigating and rectifying oil, fuel, or coolant leaks.

Procedure for tensioning and replacing drive belts.

Procedure for checking and topping up engine oil level.

Warning about fire hazards when working on the fuel system with a cold engine.

Steps for replacing the engine fuel filter and water separator.

Importance of using suitable coolant composition year-round for corrosion protection.

Warning about water entry risk when removing components below waterline.

Warning to stop the engine and break current before working on the engine.

Explanation of automatic circuit breakers for 12V and 24V systems.

Warning that low voltage circuit work requires electrical knowledge.

Key guidelines for shore power, cable routing, and ground protection.

Procedure for checking and topping up the reverse gear oil level.

Procedure for checking and topping up the drive unit oil level.

Procedure for removing, cleaning, and installing new sacrificial anodes.

Warning to prevent engine start during propeller work.

Steps for locking the propeller shaft and removing the propeller.

Checking the hydraulic steering fluid level regularly and troubleshooting low levels.

Read maintenance chapter before starting work for safe and correct operations.

Ensuring engine and drive train are not damaged during winter storage.

Caution to turn off Power Trim Assistant before taking the boat out of water.

Checking and topping up engine, stern drive, and reverse gear oil levels.

Checking stern drive anode, replacing if less than 2/3 remains.

Warning to use emery paper for cleaning anodes to avoid damaging galvanic protection.

Warning not to paint or treat sacrificial anodes or propellers.

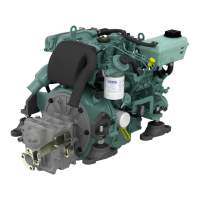

| Brand | Volvo Penta |

|---|---|

| Model | D4-300A |

| Category | Engine |

| Language | English |