Do you have a question about the Volvo Penta D12-AUX and is the answer not in the manual?

Guidelines for safe engine operation, including fuel handling and environmental considerations.

Crucial safety instructions for performing maintenance and service tasks on the genset.

Warnings about risks associated with hot engine surfaces and fluids, and chemical handling.

Information on preventing carbon monoxide poisoning from exhaust gases in confined spaces.

Volvo Penta's commitment to environmental protection and user's role in it.

Guidance on selecting appropriate fuel and lubrication oil grades for optimal performance.

Importance of regular servicing and using genuine Volvo Penta spare parts.

Specific maintenance and service demands for emission-certified engines.

Overview of the limited warranty and the crucial Warranty and Service Book.

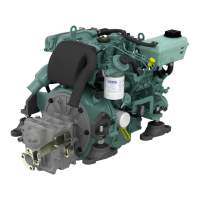

Detailed description and diagram of the D12-AUX HE Marine Genset configuration.

Detailed description and diagram of the D12-AUX RC Marine Genset configuration.

Detailed description and diagram of the D12-AUX KC Marine Genset configuration.

Importance of initial inspection for safety and maximizing service life.

Specific items to check during the external visual inspection of the genset.

Required state (open/closed) for fuel supply and coolant drain valves/plugs.

Procedure for checking electrical wiring for damage or loose connections.

References for filling the fuel, lubrication, and cooling systems.

Critical safety checks and warnings to perform before starting the genset.

Correct procedure for warming up the engine to prevent carbon buildup and ensure proper operation.

Layout and functions of the control panel for auxiliary operating mode.

Layout and functions of the control panel for emergency operating mode.

Layout and functions for combined auxiliary and emergency operating modes.

Explanation of the SDU's role in engine protection and shutdown triggers.

Procedure for identifying and resetting the broken wire fault indicator.

Instructions for testing the overspeed shutdown functionality.

Guide to using the LCD display, adjusting contrast, lighting, and configuration.

Description of different display views (System, Engine, Multi, Trip, Graph) and navigation.

Details on WARNING and STOP alarms, their indications, and alarm list management.

Troubleshooting steps for data communication loss between the system and the engine.

Step-by-step guide for starting the genset, including panel checks and mode selection.

Regular checks of the control panel, LCD screen, and indicator lamps during operation.

Procedures for responding to alarms and engine shutdowns, including acknowledgement and fault rectification.

Correct procedure for stopping the genset, including a cool-down period before shutdown.

Key safety warnings for operating the engine and maintaining engine room ventilation.

Guidance on when and how to apply load, and checks to perform during load operation.

Instructions and safety precautions for connecting and using auxiliary batteries for starting.

Procedure for stopping the engine using the emergency stop button if the control system fails.

Routine checks for leaks, fuel cocks, and maintenance scheduling after stopping.

Actions to prevent freezing damage to the raw water and freshwater systems.

Recommendations for preserving the genset during periods of inactivity or storage.

Ensuring reliability and service life through regular maintenance.

Benefits of keeping daily operation logs for maintenance and troubleshooting.

Importance of accurate maintenance and fluid records for service tuning.

Mandatory first service inspection for warranty validation.

Essential checks to be performed daily before the first start.

Routine maintenance tasks to be completed on a weekly basis.

Maintenance items for intervals of 50-500 operating hours or every 12 months.

Maintenance items for intervals of 500 operating hours or every 12 months.

Maintenance items for intervals of 1000 operating hours or every 12 months.

Specific maintenance tasks required every 2000 operating hours.

Maintenance tasks to be performed every 12 months.

Maintenance items to be performed every 24 months.

List of recommended items to be recorded daily in operation logs for analysis.

Instructions for replacing the crankcase ventilation filters.

Procedure for checking, adjusting, and changing drive belts for optimal tension.

Guidance on maintaining alternator drive belts, including tensioning.

Steps for venting the fuel system after filter changes or fuel refills.

Procedure for draining water and contaminants from the fuel filter.

Detailed instructions for changing fuel filter elements on stationary and running engines.

Instructions for draining water and contaminants from the pre-filter.

Explanation of the functions of different valve positions on the pre-filter.

Step-by-step guide for replacing filter elements in the twin pre-filter/water separator.

Procedure for checking the engine's lubrication oil level using the dipstick.

Instructions for filling the engine with the correct type and amount of lubrication oil.

Steps for changing the engine oil and filters, including by-pass filter.

Procedure for replacing switchable oil filters, including lever operation.

How to check the coolant level in the expansion tank for proper system operation.

Instructions for filling the freshwater cooling system and bleeding air.

Description of the cooling system with an engine-mounted heat exchanger.

Explanation of the genset's cooling system utilizing a radiator.

Details on cooling systems that use external heat exchangers like keel cooling.

Procedure for checking the coolant level in the expansion tank.

Instructions for filling or topping up the freshwater cooling system.

Steps for draining the coolant from the freshwater system.

How to flush the freshwater system to remove internal deposits.

Instructions for changing the coolant filter.

Procedure for draining the raw water system before maintenance work.

Instructions for checking and replacing zinc anodes in the heat exchanger.

How to inspect and clean the seawater filter.

Procedure for checking and replacing the raw water pump impeller.

Instructions for replacing the engine air filter based on the indicator.

Checking the inlet manifold drain hole for blockages and water condensation.

General information on the genset's electrical management system and voltage.

Checking electrical wiring for tightness, dryness, and freedom from oxide.

Correct usage of main switches during engine operation to prevent damage.

Information regarding the fuses in the main electric terminal box.

Safety guidelines and best practices for electric welding on the genset.

Essential safety warnings and instructions for handling and maintaining batteries.

Correct procedures for connecting and disconnecting battery cables.

Instructions for cleaning battery terminals and checking electrolyte levels.

Safety instructions and best practices for charging genset batteries.

Importance of correct conservation procedures to protect the genset during storage.

Step-by-step preparation checklist for putting the genset into storage.

Guidance on storing the genset and maintaining the battery charge.

Procedure for preparing the genset for operation after a period of storage.

A comprehensive table listing common engine symptoms and their potential causes.

Detailed specifications for the D12-AUX HE Genset engine (General, Exhaust, Lubrication, Cooling, Electrical).

Detailed specifications for the D12-AUX RC Genset engine (General, Exhaust, Lubrication, Cooling, Electrical).

Detailed specifications for the D12-AUX KC Genset engine (General, Exhaust, Lubrication, Cooling, Electrical).

Understanding sulfur content requirements and its effect on service intervals and performance.

Guidelines for selecting appropriate engine oil grades and their change intervals.

Chart and advice for choosing the correct oil viscosity based on ambient temperature.

Standards for water used in the cooling system to prevent corrosion.

Correct mixing ratio for Volvo Penta Coolant and water for optimal performance.

| Brand | Volvo Penta |

|---|---|

| Model | D12-AUX |

| Category | Engine |

| Language | English |