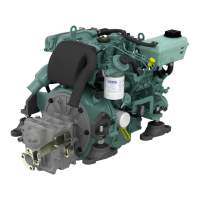

Какие надо выставлять тепловые зазоры + ТНВД форсунки Вольво Пента D13

Какие надо выставлять тепловые зазоры + ТНВД форсунки Вольво Пента D13

Explains the order of priority for safety texts and describes safety symbols.

Discusses health risks from chemicals and recommends personal protective equipment.

Details fire risks, start prevention, ventilation, and hot surface hazards.

Covers safety for spare parts, chemicals, and preventing engine start.

Warns about water entry, hot fluids, refueling risks, and fuel quality.

Addresses battery handling, polarity, electrolyte risks, and component cleaning.

Provides a checklist of essential items to remember before embarking on a boat trip.

Explains the purpose and content of the operator's manual for maximum benefit.

Covers warranty terms and provides advice for new boat owners.

Details the recommended procedure for breaking in the engine during initial operation.

Specifies requirements for fuel, oils, coolant, and parts for engine reliability.

Warns against applying external loads to engine and transmission components.

Discusses environmental commitment and policies regarding engine data recording.

Outlines special requirements for care and maintenance of certified engines.

Describes the dealer network and the 24/7 support service for assistance.

Introduces the Exhaust Aftertreatment System and explains AUS/DEF fluid.

Provides shut-down instructions and illustrates major components of the EATS system.

Describes AUS/DEF tank configuration, monitoring, storage, and handling safety.

Advises on cleaning tools and clothing after contact with AUS/DEF fluid.

Introduces the MCC system and provides an overview of its components.

Details the functions of MCU panel buttons, indicators, and display information.

Guides on navigating through system menus like Monitoring, Settings, and History.

Covers settings for serial number, backlighting, language, and password protection.

Explains engine working modes (Local, Operations, Off) and how to access statistics.

Introduces the alarm system, display, and acknowledgment procedures.

Explains the SDM function, reset procedure, and warnings for override mode.

Lists essential checks and warnings before starting the engine, including start spray prohibition.

Guides on selecting start mode, checking status, and troubleshooting 'Not Ready'.

Advises on safe handling of engine controls and avoiding sudden maneuvers.

Explains how to acknowledge and manage engine alarms displayed on the MCU.

Details the correct procedure for shifting between forward and reverse gears.

Covers IMO regulation compliance and procedures for switching between IMO Tiers.

Recommends engine idling before shutdown and warns about post-ignition switch-off timing.

Explains how to use the auxiliary stop if normal engine shutdown fails.

Lists checks after shutdown and advises on engine care during operation breaks.

Advises on draining systems and checking battery charge in cold weather conditions.

Explains how malfunctions are indicated and their impact on engine operation.

Describes accessing the alarm list, its headings, and interpreting alarm statuses.

Explains ECU alarm codes, FMIs, and common abbreviations used in fault reporting.

Links engine symptoms to potential causes and corresponding reference pages.

Lists further potential causes for various engine malfunctions.

Details fault codes for air filter, inlet temperature, and ambient temperature sensors.

Covers fault codes for battery, bridge stop, coolant level, and CAN communication.

Explains fault codes for oil issues, EATS, ECU program, emergency stop, and relays.

Details fault codes for throttle demand, fuel pressure, DEF pump, and purge valve.

Covers fault codes for gear oil pressure, injector issues, and sensor supply failures.

Explains fault codes for urea quality, level, temperature, pump, and exhaust temperature.

Details fault codes for water in fuel, miscellaneous warnings, derate alarms, and underspeed.

Lists potential faults that trigger engine safety functions and how to respond.

Provides crucial instructions and warnings for jump-starting with auxiliary batteries.

Outlines recommended service intervals based on time and operating hours.

Details the procedure for a general visual inspection of the engine and engine bay.

Guides on changing the air filter and inspecting drive/alternator belts.

Details the process for changing the drive and alternator belts.

Guides on checking oil level, changing engine oil, and oil filters.

Covers fuel system requirements, filter replacement, and bleeding procedures.

Details coolant requirements, mixing, filling, draining, and flushing procedures.

Guides on draining, anode check/replacement, and impeller check/replacement.

Explains how to check and clean the seawater filter and intake manifold drain hole.

Details filling AUS/DEF, pump filter changes, and warnings about erroneous filling.

Explains main switch function and checks for electrical connections.

Covers battery maintenance, safety, charging, and replacement procedures.

Discusses electrical installation safety, grounding, and leakage current.

Details critical safety instructions for performing electrical welding on the engine.

Outlines the critical steps for inhibiting the engine and boat for long-term storage.

Explains conservation methods and preparation steps for bringing the boat out of storage.

Lists detailed technical specifications for various engine models.

Provides data on oil capacity, pressure, quality, and change intervals.

Details fuel quality requirements for diesel engines with aftertreatment systems.

Provides cooling system capacity and coolant mixing recommendations.

Lists water quality standards and electrical system specifications.

Shows where to locate product, chassis, and serial numbers.

| Engine Model | D13 |

|---|---|

| Displacement | 12.8 liters |

| Bore | 131 mm |

| Stroke | 158 mm |

| Fuel System | Common rail direct injection |

| Engine Type | In-line 6-cylinder |

| Aspiration | Turbocharged |

| Emission Compliance | EPA Tier 3 |

| Weight (Dry) | Approximately 1600 kg |

| Cooling System | Heat exchanger cooled |