Do you have a question about the Volvo Penta D6-280A and is the answer not in the manual?

Precautions for fueling to prevent fire and explosion risks.

Advice on avoiding sudden movements and propeller hazards.

Instructions on when not to start the engine due to potential hazards.

Explains risk of CO poisoning from exhaust fumes in cockpit/cabin due to turbulence.

Importance of using Volvo Penta approved parts and services for reliability.

Description of various engine gauges like fuel, oil pressure, and temperature.

Explains the hydraulic trim system and its effect on boat passage.

How to operate the Power Trim panel or side-mounted buttons.

Details on using the Power Trim panel for single/twin engine adjustments.

How correct trim settings improve driving comfort and response.

Describes single-lever control for gearshift/throttle and neutral position.

Control for docking and maneuvering at low speed in confined marinas.

How to maneuver the boat using the joystick (forward, aft, abeam, twist).

Activating, exiting, and managing docking mode and high mode.

Step-by-step guide to calibrate the joystick for accurate boat control.

Procedure to reset the joystick calibration to default settings.

Checks for oil, coolant, sea cock, fuel cock, switches, fan, fuel, and stern drive.

How to shift gears to neutral and turn the ignition on.

Ensuring control levers are in neutral for all stations before starting.

Turning the starter key to position I to activate the ignition.

Starting the engine using ignition switch or starter button from any station.

Procedure for starting the engine with the ignition key.

Procedure for starting each engine using its starter button.

Allowing engine to idle, checking instruments, and warming up before full power.

Importance of reading all instruments and alarm displays regularly during voyage.

How alarms and messages are displayed and acknowledged.

Shifting between forward and reverse at idling for smooth operation.

Procedures for stopping the engine using the key or stop button.

Procedure to stop the engine using the starter key.

Procedure to stop the engine using the stop button.

How the engine and EVC system warn drivers of malfunctions.

Malfunction messages, their impact on the engine, and tasks to perform.

Steps to acknowledge alarms and silence buzzers.

How to view the fault list, its causes, and remedies.

How stored faults are deleted automatically or must be acknowledged.

Symptoms like no start, rough running, and speed issues with possible causes.

Symptoms like knocks, vibration, fuel consumption, and exhaust smoke with causes.

Symptoms like low oil pressure, high coolant temp, and low coolant temp with causes.

Messages shown on display with descriptions and suggested actions.

Covers engine, EVC, multilink, transmission, and control lever faults.

Covers steering wheel, coolant level, temperature, and oil level/pressure faults.

Covers primary battery, sensor, and steering system failures.

Action required: Empty water separator under fuel filter.

Procedures for kick-up function, checking drive, and propeller after grounding.

Inspection of tie rod for damage after grounding; contact workshop if bent or loose.

Step-by-step guide for jump-starting a discharged battery with an auxiliary battery.

How to manually engage gears if control lever shifting fails.

Description of electronically shifted reverse gear and manual engagement.

Steps to manually engage gears by disconnecting solenoid valve wiring.

Using trim buttons to trim drive in emergencies; warnings about damage.

Steps for restarting the engine after a crash-stop, including acknowledging alarms.

Covers warranty inspection, 50-100 hour service, and 50-200 hour/12 month service.

Steps for changing engine oil and filters, including warm-up and checks.

Procedure for replacing oil and by-pass filters during oil changes.

Procedure for replacing the engine fuel filter and water separator.

Procedure to bleed the fuel system after filter changes or tank run dry.

Correct mixing ratios for Volvo Penta coolant and water for optimal protection.

How to check and top up the reverse gear oil level.

Procedure for changing reverse gear oil and filter.

How to check and top up the drive unit oil level.

Procedure for changing transmission oil, including propeller removal and reinstallation.

Steps for conserving the engine and drive train for non-use periods.

Tasks like changing oil, filters, and running engine until normal temperature.

Cleaning hull, drive, changing oil, conserving systems, and checking coolant.

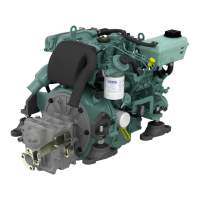

| Engine Model | D6-280A |

|---|---|

| Max Engine Speed | 3500 rpm |

| Fuel System | Common rail direct injection |

| Compression Ratio | 17.5:1 |

| Aspiration | Turbocharged |

| Engine Type | In-line 6-cylinder |

| Displacement | 5.5 L |

| Rated Power | 280 hp |

| Cooling System | Freshwater cooling |

| Bore | 103 mm (4.06 in) |

| Stroke | 110 mm |

| Emissions Compliance | IMO Tier II, US EPA Tier 3 |