39

1

2

3

Fuel system

All work on the engine injection pump or injectors must be carried out at an authorized workshop. Use only the

recommended grade of fuel: See the chapter “Technical Data”.

WARNING! Fire risk. When carrying out work on the fuel system make sure the engine is cold. A fuel spill

onto a hot surface or an electrical component can cause a fire. Store fuel soaked rags and other flammable

material in fireproof conditions.

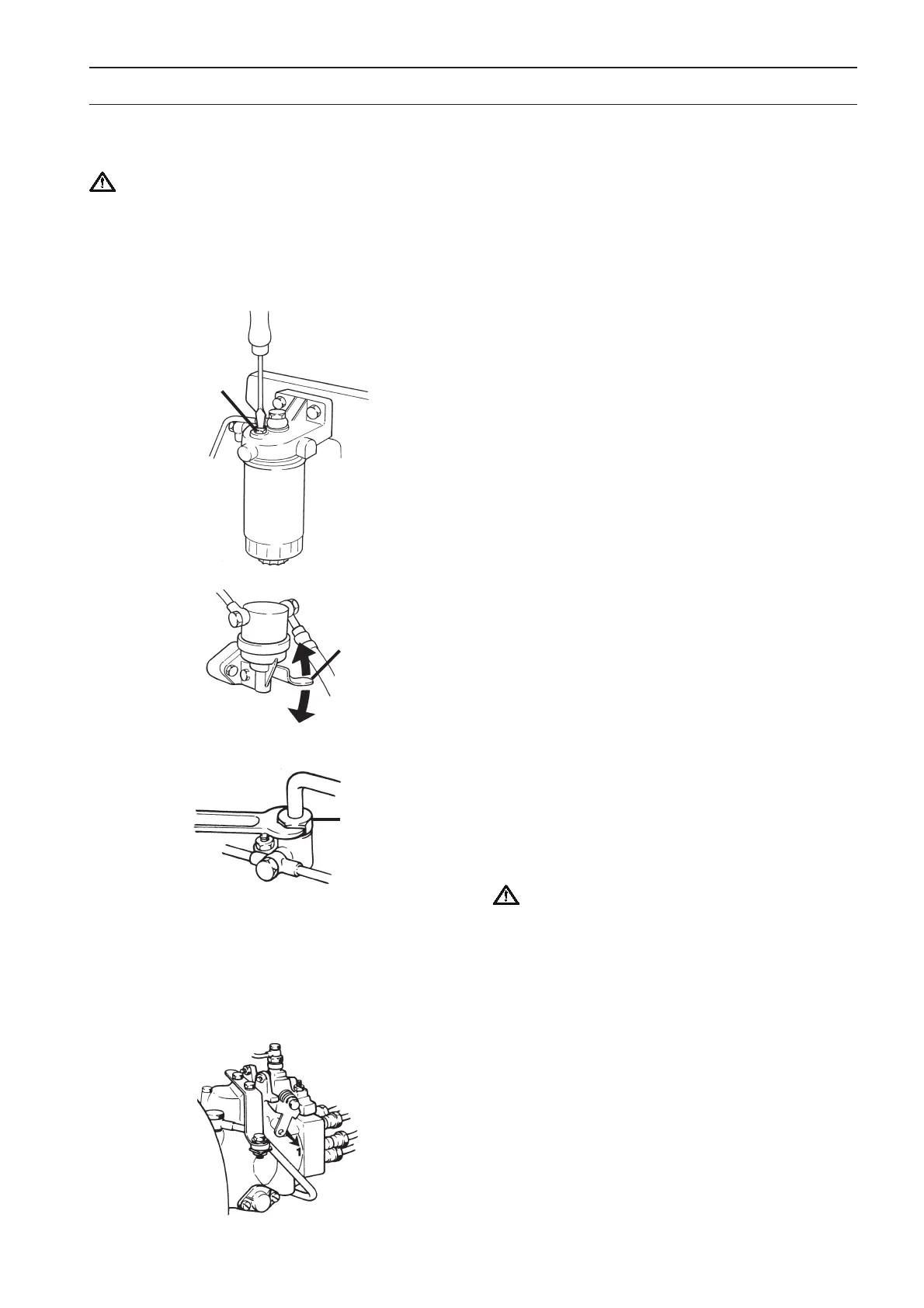

Venting the fuel system

The fuel system must be vented after the fuel filters

have been replaced or after refilling the fuel tank after

it has been run dry.

1. Open vent screw (1) on the filter mounting approxi-

mately four turns. Avoid fuel spillage. Use rags

around the venting point.

2. Pump the fuel using hand pump (2) until there are

no more air bubbles visible in the fuel. Continue

pumping and at the same time tighten the venting

screw. If the pump effect is poor, turn the engine

over slightly so that the pump drive cam changes

position.

If the engine does not start continue venting as

follows:

3. Use the handpump (2) and pump for about half a

minute to automatically vent the fuel injection

pump.

4. Slacken off the injector delivery line nuts and set

the engine speed control to wide open throttle

(WOT). Turn the engine over with the starter motor

until fuel comes out of the delivery lines. Avoid

fuel spillage. Tighten delivery line nuts.

5. Start the engine and check for leaks.

WARNING! Approaching a running engine is

dangerous. Watch out for rotating components

and hot surfaces.

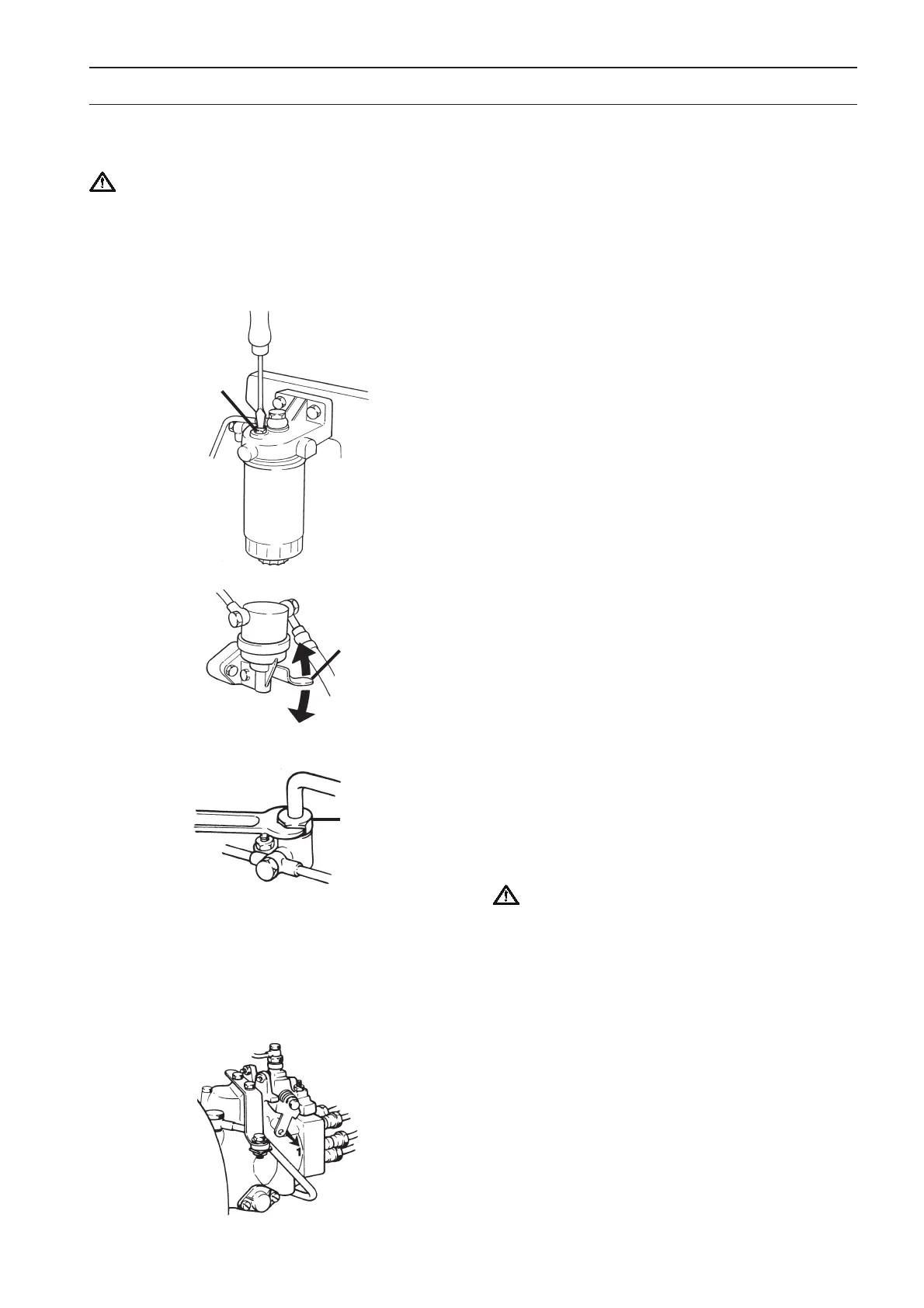

Emergency stop

Should the normal stop function not operate the

engine can be stopped by pulling the fuel injection

pump lever (1) to the rear.

Loading...

Loading...