Tank

IMPORTANT:

Dirt/dust, oil, greases, detergents and any chemicals

and

natural products must be prevented from entering

the Adblue/DEF tank.

The system will be damaged if dust or dirt enters the

tank clogging the filters in the dosing system.

Keep the tank clean at all times.

The AdBlue

®

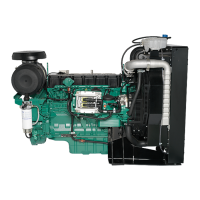

/DEF-solution is stored in a separate

tank.

Tanks are made of plastic and are available in different

shapes and sizes.

There is a fitting in the tank that comprises a heating

coil (1), a float (2) and a filter (3) on the suction line to

prevent any particles from circulating through the

system and causing disruptions.

The filter must be checked and cleaned as necessary.

There is a drain plug (4) on the bottom of the tank so

that the solution can be emptied when necessary, e.g.

for cleaning.

The tank is fitted with a breather to equalize pressure

changes.

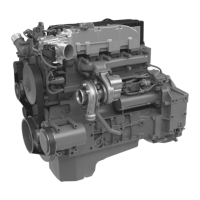

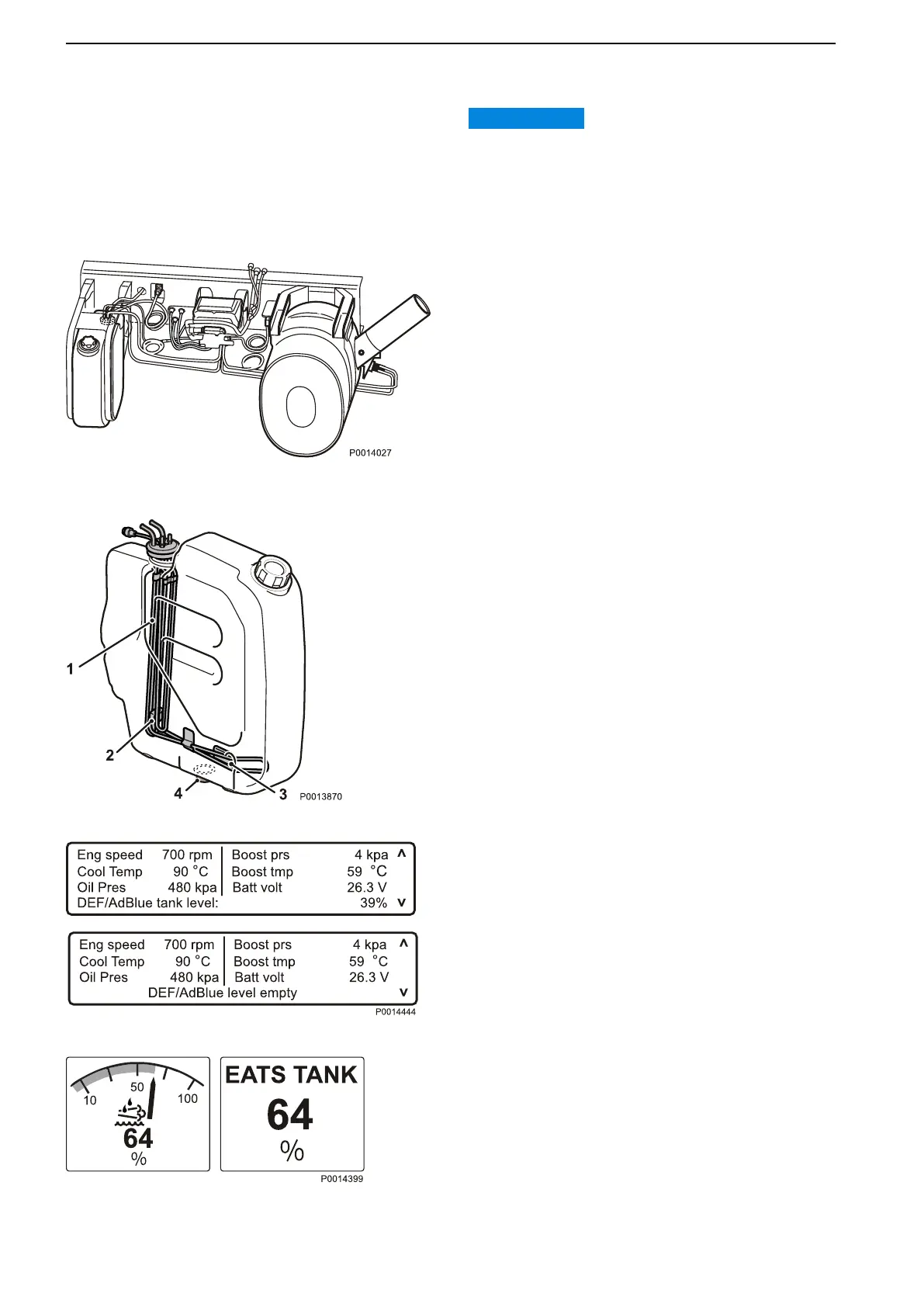

Tank level

AdBlue

®

/DEF solution consumption varies during

operations. The level in the tank is shown on the gauge

as a percentage of the total tank volume.

When the level in the tank falls below the limit, the level

sensor in the tank transmits a signal that closes the

injection valve. A fault code is set in the engine control

unit, a warning lamp lights up and a fault message is

shown on the control panel. If AdBlue

®

/DEF solution is

not added, injection into the exhaust pipe will cease

and engine rpm and torque will be limited. When

AdBlue

®

/DEF is added the fault message is canceled

and the engine is once again able to deliver full power.

Refer to Fault handling, page 58 for further

information.

Should the AdBlue

®

/DEF tank become empty during

operations this will not lead to damage to the engine or

Example of the location of an AdBlue

®

/DEF tank.

DCU

DU

Presentation

28

47711097 09-2018 © AB VOLVO PENTA

Loading...

Loading...