Do you have a question about the Volvo Penta TAD870VE and is the answer not in the manual?

Contains information for correct, safe operation and maintenance of the Volvo Penta engine.

Information on the limited warranty for new Volvo Penta engines and conditions for validity.

Perform visual checks of the engine and compartment before and after operation.

Use appropriate safety equipment to reduce injury risk during operation.

Wear safety glasses to protect eyes from splinters, sparks, and chemical spray.

Avoid oil contact with skin. Use protective gloves and wash hands regularly.

Keep flammable materials away from sparks and open flames. Ensure ventilation.

Use genuine Volvo Penta parts to minimize risks of explosion or fire.

Handle hazardous waste properly and dispose of it at approved facilities.

Immobilize engine with main switch and disconnect battery cables before starting work.

Start engine only in well-ventilated areas. Ensure exhaust ventilation.

Be cautious of moving parts and hot surfaces. Never work on a running engine.

Ensure warning and information decals are visible and legible.

Never use start spray or similar agents to start the engine due to explosion risk.

Check for fuel/gas leaks and ensure air filter and caps are fitted before starting.

Stop engine, disconnect current at main switches before electrical work.

Switch off main switch before connecting or disconnecting connectors.

Disconnect connections to control units before welding and reconnect after.

Stop engine and let it cool before working on the cooling system.

Avoid opening hot coolant filler cap. Release pressure slowly.

Ensure lubrication system is not pressurized before working on hot oil.

Risk of fire and explosion during refueling. Smoking is forbidden.

Use recommended fuel. Wrong quality can damage the engine and increase costs.

Comply with regulatory requirements for certified emission levels.

Wear safety goggles and be careful with high-pressure fuel circuits.

Do not bend or straighten high pressure fuel pipes. Replace damaged pipes.

Risk of fire and explosion. Avoid sparks and open flames near batteries.

Ensure correct connection of battery cables to terminals to avoid damage.

Wear goggles when handling batteries. Electrolyte is corrosive.

Ensure the battery compartment is designed according to current safety standards.

Never use a high pressure washer for cleaning engine or components.

Observe meticulous cleanliness when handling system components.

Clutch adjustments must be carried out with the engine stopped.

Proper engine break-in procedure for the first 10 operating hours.

Use recommended fuels and oils. Follow maintenance intervals for filters.

Use genuine parts for reliability and longevity. Contact authorized dealers.

Do not step on or apply external loads to engine or components.

Volvo Penta's commitment to energy efficiency and low emissions.

Demands on care and maintenance for emission-certified engines.

Information on the AdBlue®/DEF system for emission control.

Information on authorized dealers for service and repair.

24-hour phone-based breakdown and support service.

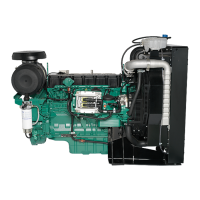

Overview of the industrial diesel engines covered by the manual.

Description of the electronic system for diesel engine control and diagnostics.

System used to reduce emissions by treating exhaust gases with AdBlue®/DEF.

Procedure to prevent damage from freezing and spillage of AdBlue®/DEF solution.

Diagram and description of the EATS system components.

Details on the AdBlue®/DEF tank, its components, and maintenance.

Monitoring AdBlue®/DEF tank level and its impact on engine operation.

Description of the heating system for the AdBlue®/DEF tank and hoses.

Recommendations for storing AdBlue®/DEF to prevent breakdown and evaporation.

Safety precautions and guidelines for handling AdBlue®/DEF fluid.

Guidelines for cleaning tools and clothes that have contacted AdBlue®/DEF.

First aid measures for skin, eye, and inhalation contact with AdBlue®/DEF.

Description of the DCU II instrument panel and its functions.

Overview of the three main menus: Engine Data, Diagnostics, and Settings.

Indicates active malfunctions with symbols for emission and EMS system issues.

Types of messages (Alarm, Warning, Message) and their severity.

Details on accessing and navigating Engine Data, Diagnostics, and Settings menus.

Options to save, restore last, or restore default display settings.

Settings that should only be changed by authorized technicians.

Pre-start checks including oil level, fuel pre-filter, fluid levels, and leaks.

Procedure for starting the engine, including pre-heating and starter motor limits.

Preparations for starting in extreme cold, including fuel, oil, and battery considerations.

Warning against using start spray due to explosion risk.

Procedure for starting the engine using auxiliary batteries, with safety warnings.

Check instruments after starting and regularly during operation.

How the EMS system indicates malfunctions via fault codes, lamps, and audible warnings.

General advice for maneuvering the engine.

Avoid long-term operation at idle or low load to prevent issues like slobber.

Run engine at high idle for 3-5 minutes before shutdown to equalize temperatures.

Procedure to stop the engine and turn off the ignition.

Information on the location of the extra stop function.

Checks after shutdown, turning off main switches, and maintenance.

Monitors, controls, and protects the engine and system from damage.

Fault codes reset when power is disconnected; use VODIA tool for erasure.

Table of symptoms and possible causes of engine malfunctions.

System monitoring for AdBlue quality, level, and component function.

Checks for system component connectivity and potential leaks.

Actions taken by the system for low tank level or quality/component faults.

Service intervals for engine reliability and warranty validity.

General inspection of engine and compartment for leaks and loose parts.

Inspect charge air hoses, unions, and clamps for cracks and leaks.

Identification of key engine components like filler caps, dipstick, and filters.

Procedure for checking drive belt tension and replacing worn or damaged belts.

Information on oil change intervals and recommendations based on engine use.

Steps for checking and topping up engine oil level on level ground.

Procedure for replacing the engine oil filter, with safety warnings.

Procedure for changing engine oil and filter, including warm-up and checks.

Safety precautions and general advice for working on the fuel system.

Procedure for draining water and condensate from the fuel pre-filter.

Steps for replacing the fuel filter, emphasizing cleanliness and correct type.

Procedure for replacing the fuel pre-filter and water separator.

Procedure for purging the fuel system after maintenance or if it runs dry.

Ensures engine operates at correct temperature; always fill with coolant mixture.

Guidance on mixing coolant with water, emphasizing OAT technology.

How to check and top up the coolant level in the expansion tank.

Steps for refilling and bleeding the cooling system after it has been emptied.

Procedure for draining the coolant from the radiator and engine block.

How to clean the charge air cooler using wash or compressed air.

Procedure for cleaning the cooling system to remove deposits.

Instructions and precautions for filling the AdBlue®/DEF tank.

Consequences of filling the wrong fluid into diesel or AdBlue®/DEF tanks.

Procedure for changing the AdBlue®/DEF pump filter.

Safety instructions for operating the main switch.

Information on engine and ETAS system fuses and overload protection.

Check electrical connections for dryness, oxide, and secure tightening.

Safety, maintenance, and charging recommendations for batteries.

Procedures for conserving the engine for short periods of non-use.

Procedures for conserving the engine for extended periods of non-use.

Steps to prepare the engine for use after a storage period.

Detailed steps for conserving lubrication and fuel systems for long-term storage.

Specifications for TAD570VE-TAD572VE and TAD870VE-TAD873VE engine series.

Oil capacity, oil pressure, oil filter type, and lube oil pump details.

Recommended oil quality and service intervals.

Guidance on selecting oil viscosity based on ambient temperature.

Fuel quality requirements for diesel engines with aftertreatment systems.

Technical data for the cooling system, including pressure cap and thermostat.

Recommendations for mixing coolant, including water quality requirements.

Specifications for water quality used in coolant mixtures according to ASTM D4985.

Usable volume data for different tank sizes in the inlet and exhaust system.

Data for batteries, alternator performance at different temperatures, and starter motor output.

Location and types of engine labels and identification numbers.

| Engine Model | TAD870VE |

|---|---|

| Number of Cylinders | 6 |

| Compression Ratio | 17.5:1 |

| Aspiration | Turbocharged |

| Charge Air Cooler | Yes |

| Fuel System | Common Rail |

| Cooling System | Liquid-cooled |

| Emission Standards | EU Stage V |

| Configuration | Inline |

| Height | 1, 200 mm |

| Engine Type | In-line 6-cylinder diesel engine |

| Displacement | 7.7 l (469 cu. in) |