Do you have a question about the Volvo Penta TAD871VE and is the answer not in the manual?

Perform visual checks on the engine and engine compartment before and after operation.

Always use appropriate personal protective equipment for safety.

Always wear safety glasses to prevent eye injury from sparks or chemicals.

Avoid prolonged skin exposure to oil; use protective gloves and wash hands.

Be aware of fire and explosion risks from fuels, lubricants, and battery gases.

Use genuine Volvo Penta parts to minimize fire or explosion risks.

Dispose of used oils and chemicals as hazardous waste at approved facilities.

Immobilize the engine by switching off the main switch before starting work.

Always start the engine in a well-ventilated area; vent exhaust outside if enclosed.

Be cautious of moving parts and hot surfaces to avoid serious personal injury.

Ensure all warning and information decals on the product are visible and legible.

Never use start spray or similar agents to start an engine due to explosion risk.

Check for fuel/gas leaks and ensure air filter and caps are fitted before starting.

Stop the engine and disconnect power before working on the electrical system.

Switch off the main switch before connecting or disconnecting connectors.

Disconnect all control units before welding and reconnect after.

Stop the engine and let it cool before working on the cooling system.

Open coolant filler caps slowly when hot to release pressure and avoid burns.

Ensure the lubrication system is not pressurized before working on it.

Refuel in a well-ventilated area; stop the engine and no smoking.

Use only recommended fuel; wrong quality can damage the engine and cause overspeed.

Use recommended fuel to meet regulatory requirements for certified emission levels.

Wear safety goggles; be careful with high-pressure fuel circuits to avoid infection.

Do not bend or straighten fuel pipes; replace damaged pipes immediately.

Avoid open flames or sparks near batteries; a spark can cause explosion.

Ensure correct connection of positive (+) and negative (-) battery cables to avoid damage.

Handle batteries with care; electrolyte is corrosive. Rinse exposed areas immediately with water.

Ensure the battery compartment is designed according to current safety standards.

Never use a high-pressure washer for cleaning the engine or components.

Observe meticulous cleanliness when handling system components to prevent breakdowns.

Clutch adjustments must be carried out with the engine stopped.

This manual contains information for safe operation and maintenance of your Volvo Penta engine.

Your new engine is covered by a limited warranty; read and implement service requirements.

Follow specific procedures for the first 10 operating hours for optimal engine life.

Use recommended fuels and oils; follow maintenance intervals for engine longevity.

Regular servicing and genuine Volvo Penta parts ensure reliability and longevity.

Do not stand or step on engine components; loads can cause damage and malfunction.

Volvo Penta prioritizes environmental care, energy efficiency, and low emissions.

Emission-certified engines require special care; follow maintenance to maintain certificate.

EATS reduces emissions using AdBlue®/DEF and SCR technology.

Contact authorized dealers for high-quality service and repair work.

24/7 phone-based breakdown and support service backed by the dealer network.

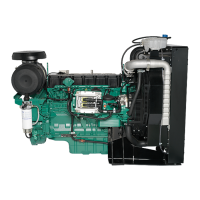

Manual covers TAD570VE-TAD572VE (4-cylinder) and TAD870VE-TAD873VE (6-cylinder) engines.

Electronic system for engine control, fuel regulation, and diagnostics.

EATS reduces emissions using AdBlue®/DEF and SCR technology.

A 32.5% urea solution (ISO 22241) used for exhaust treatment; corrosive to metals.

System monitors AdBlue®/DEF quality, level, and component function; reduces power on faults.

System drains automatically when engine is stopped normally; wait 2 minutes before disconnecting hoses.

Diagram and component list for the EATS system.

Tank contains heating coil, filter, quality sensor; keep clean to prevent damage.

Level sensor stops dosing below set limit; warning shown on panel; limited power if empty.

Tank and hoses are heated by engine coolant and electrical elements to prevent freezing.

Store solution below 25°C and out of direct sunlight; allow for expansion upon freezing.

Handle with care; avoid contact with eyes/skin, rinse thoroughly if contact occurs.

Absorb spills with dry sand; do not wash into drains. Handle according to regulations.

Clean tools and clothes thoroughly to prevent damage from AdBlue®/DEF contamination.

Flush skin/eyes with water, seek medical attention if necessary.

Instrument panel for engine control, monitoring, and diagnostics.

Main menus: Engine Data, Diagnostics, and Settings.

Displays symbols for active malfunctions in the top right of the screen.

Messages are color-coded by severity: ALARM (red), WARNING (yellow), MESSAGE (blue).

Details for Engine Data, Diagnostics, and Settings menus including language options.

Save current, restore last, or restore default display settings.

Advanced settings like I/O Status, CAN Termination, Speed Control are dealer configurable.

Never use start spray or similar agents to start an engine due to explosion risk.

Check oil level, fuel pre-filter, leaks, coolant level, and radiator condition.

Do not open hot coolant filler cap except in emergencies due to burn risk.

Never break circuit with main switch while engine is running to avoid damage.

Pre-heating adjusts to engine temperature; starter motor connection is time-limited.

Press the power button to switch on ignition, then press START to start the engine.

Use approved fuel, synthetic oil, pre-heat coolant, ensure glycol mixture and good battery condition.

Using start spray can cause engine manifold explosion and personal injury.

Connect batteries correctly; ensure good ventilation to avoid explosion hazard.

Check instruments after starting and regularly during operation. Check oil level daily.

EMS generates fault codes/alarms via lamps and audible warnings for malfunctions.

General advice for operating the engine.

Avoid long-term low load operation to prevent oil dilution, carbon build-up, and wear.

Run in engine, reach working temp quickly, avoid long idle, avoid <20% load, test run annually.

Run engine at high idle for 5 minutes after normal use to cool turbochargers and equalize temp.

Do not turn off the main switch within 30 seconds after turning off ignition to save engine data.

Disengage clutch, press STOP button, then press power button to turn off ignition.

Refer to Maintenance, page 54 for location of the extra stop.

Watch out for rotating components and hot surfaces when working near a running engine.

Check for leaks, turn off main switches for long stoppages, carry out maintenance.

Warm up engine every two weeks; conserve for >2 months; ensure antifreeze protection.

Monitors, controls, and protects engine/systems; informs of faults via fault codes.

Displays fault codes; use arrow buttons and OK to view details and remedies.

Power cycle resets memory; VODIA tool needed to erase codes for uncorrected faults.

Table of symptoms and possible causes for engine malfunctions.

System monitors EATS components; warns operator and limits engine speed/torque on faults.

Yellow warning symbol for fault or low AdBlue®/DEF; red symbol for major faults or very low level.

Check connections, hoses, pump, sensors, and leaks for quality issues.

Details power reduction, torque limits, and idle speed based on AdBlue®/DEF level and faults.

Lists fault codes (SPN/FMI) and corresponding engine components.

Details intervals for regular and extended service, including types A-F.

Intervals can be extended based on oil analysis and Volvo Penta's conditions.

Read safety advice before starting any work. Engine must be stopped unless specified.

Stop engine, remove key, and cut voltage before opening or removing engine covers.

Visually inspect engine and compartment for leaks, loose bolts, worn belts, or damaged cables.

Inspect charge air hoses and unions for cracks; check exhaust system for leaks.

Check belt tension and condition; replace if oily, worn, or damaged.

Oil change intervals vary by grade, fuel sulfur, and running conditions.

Check oil level on level ground; do not fill above MAX mark.

Always follow recommended oil change intervals and replace the oil filter simultaneously.

Run engine until warm, drain oil, replace filter, fill to correct level, check for leaks.

Ensure engine is cold for work; store fuel-soaked rags safely.

Drain water from the water separator into a collection vessel.

Use approved filters; keep fuel system unions clean to prevent engine breakdown.

Use protective gloves; collect condensate and fuel; store used filter safely.

Purge fuel system after maintenance or if it runs dry; use hand pump until no air bubbles.

Ensure system is filled with correct coolant mixture for corrosion and freeze protection.

Use same coolant type; mix with distilled/deionized water; check water quality.

Check level on level ground; top up to between MIN and MAX marks on expansion tank.

Check drain points closed; fill with coolant, bleed air, run engine to operating temp, check level.

Stop engine; open drain points to drain coolant. Do not drain system if for storage.

Cover engine; clean cooler with high pressure wash or compressed air when cold.

Clean system to remove deposits; use coolant for cleaning if necessary; flush with clean water.

General information about the inlet and exhaust system.

Handle with care; use correct nozzle and solution; avoid spilling on hot components.

Filling wrong tank causes engine damage; use correct cap and avoid confusion.

Stop engine, disconnect battery, place collection vessel, undo filter cover, pull out filter.

Single-pole 24V system with alternator; stop engine before working on electricals.

Never disconnect current with engine running or by removing battery cables.

Two fuses: engine (15A) and EATS (25A). Contact workshop if fuses trip frequently.

Ensure electrical connections are dry, free from oxide, and securely tightened.

Risk of fire/explosion; handle electrolyte with care; ventilate compartment; keep clean and charged.

Ensure new battery meets specs; do not disconnect with engine running; connect poles correctly.

Change oil/filter, run engine warm. Ensure coolant has antifreeze properties.

Conserve lubrication/fuel systems, drain fuel filters, clean/charge batteries, empty AdBlue/DEF tank.

Remove covers, fill oil, install fuel filters, check belts/hoses, connect batteries, start engine.

Use conservation oil in engine/fuel system, run engine, drain oil, bleed fuel system.

Specifications for TAD570VE-TAD572VE (4-cylinder) and TAD870VE-TAD873VE (6-cylinder) engines.

Oil capacity, sump levels, oil pressure, oil filter type, and lube oil pump.

Recommended oil quality (VDS-4.5) and service interval (500 hours/12 months).

Select oil viscosity based on ambient temperature chart.

Fuel quality requirements for diesel engines with aftertreatment systems.

Approves HVO/GTL fuels if they comply with EN 15940 and service requirements.

Details pressure cap, coolant volume, and thermostat opening temperature.

Use same coolant type; mix with distilled/deionized water; check water quality.

Specifies acceptable limits for water quality parameters like hardness, pH, and conductivity.

Tank usable volumes for different system sizes.

Details system voltage, battery capacity, alternator output, and starter motor output.

Locates engine labels (designation, serial number) and explains label information.

Declaration regarding Machinery Directive compliance and applied standards.

| Engine Model | TAD871VE |

|---|---|

| Rated Speed | 2200 rpm |

| Fuel System | Common rail |

| Emission Level | EU Stage V |

| Engine Type | Diesel |

| Displacement | 7.7 L |

| Aspiration | Turbocharged |

| Cooling System | Water-cooled |