T

r

a

c

k

u

n

i

t

,

a

d

j

u

s

t

i

n

g

t

e

n

s

i

o

n

W

A

R

N

I

N

G

Risk of serious injury

Recoil spring cylinder is filled with pressurised

grease. High pressure grease in the cylinder could

cause serious injury or death.

A

l

w

a

y

s

k

e

e

p

f

a

c

e

,

h

a

n

d

s

a

n

d

b

o

d

y

a

w

a

y

f

r

o

m

t

h

e

g

r

e

a

s

e

n

i

p

p

l

e

a

n

d

v

a

l

v

e

w

h

e

n

a

d

j

u

s

t

i

n

g

t

h

e

t

r

a

c

k

t

e

n

s

i

o

n

o

r

l

o

o

s

e

n

i

n

g

t

h

e

t

r

a

c

k

.

N

e

v

e

r

r

e

m

o

v

e

t

h

e

g

r

e

a

s

e

f

i

t

t

i

n

g

o

r

n

u

t

a

n

d

v

a

l

v

e

a

s

s

e

m

b

l

y

t

o

r

e

l

e

a

s

e

g

r

e

a

s

e

.

T

i

g

h

t

e

n

i

n

g

t

r

a

c

k

t

e

n

s

i

o

n

-

r

e

d

u

c

i

n

g

s

l

a

c

k

1 Fill the grease through grease nipple (B) using a

grease gun with high pressure.

2 Check the tension by moving the machine

forward and rearward.

3 Check the tension again. If not correct, adjust it

again.

L

o

o

s

e

n

i

n

g

t

r

a

c

k

t

e

n

s

i

o

n

-

i

n

c

r

e

a

s

i

n

g

s

l

a

c

k

1 Loosen the valve (A) gradually to drain the

grease, but not more than one turn.

If the grease does not drained smoothly, move

the machine forward and rearward.

R

i

s

k

o

f

e

n

v

i

r

o

n

m

e

n

t

a

l

p

o

l

l

u

t

i

o

n

!

T

h

e

g

r

e

a

s

e

i

n

t

h

e

t

r

a

c

k

a

d

j

u

s

t

m

e

n

t

c

y

l

i

n

d

e

r

i

s

u

n

d

e

r

h

i

g

h

p

r

e

s

s

u

r

e

a

n

d

l

a

r

g

e

q

u

a

n

t

i

t

i

e

s

o

f

g

r

e

a

s

e

w

i

l

l

b

e

q

u

i

c

k

l

y

r

e

l

e

a

s

e

d

i

f

t

h

e

v

a

l

v

e

i

s

l

o

o

s

e

n

e

d

t

o

o

m

u

c

h

.

N

e

v

e

r

l

o

o

s

e

n

t

h

e

v

a

l

v

e

b

y

m

o

r

e

t

h

a

n

t

w

o

t

u

r

n

s

w

h

e

n

d

r

a

i

n

i

n

g

t

h

e

g

r

e

a

s

e

.

2 Close the valve (A) but do not tighten

excessively as the fitting may be damaged.

- The valve (A) assembly, tightening torque: 7.0

kgf m (51 lbf ft) (69 N m)

3 Check the tension by moving the machine

forward and rearward.

4 Check the tension again. If not correct, adjust it

again.

B

A

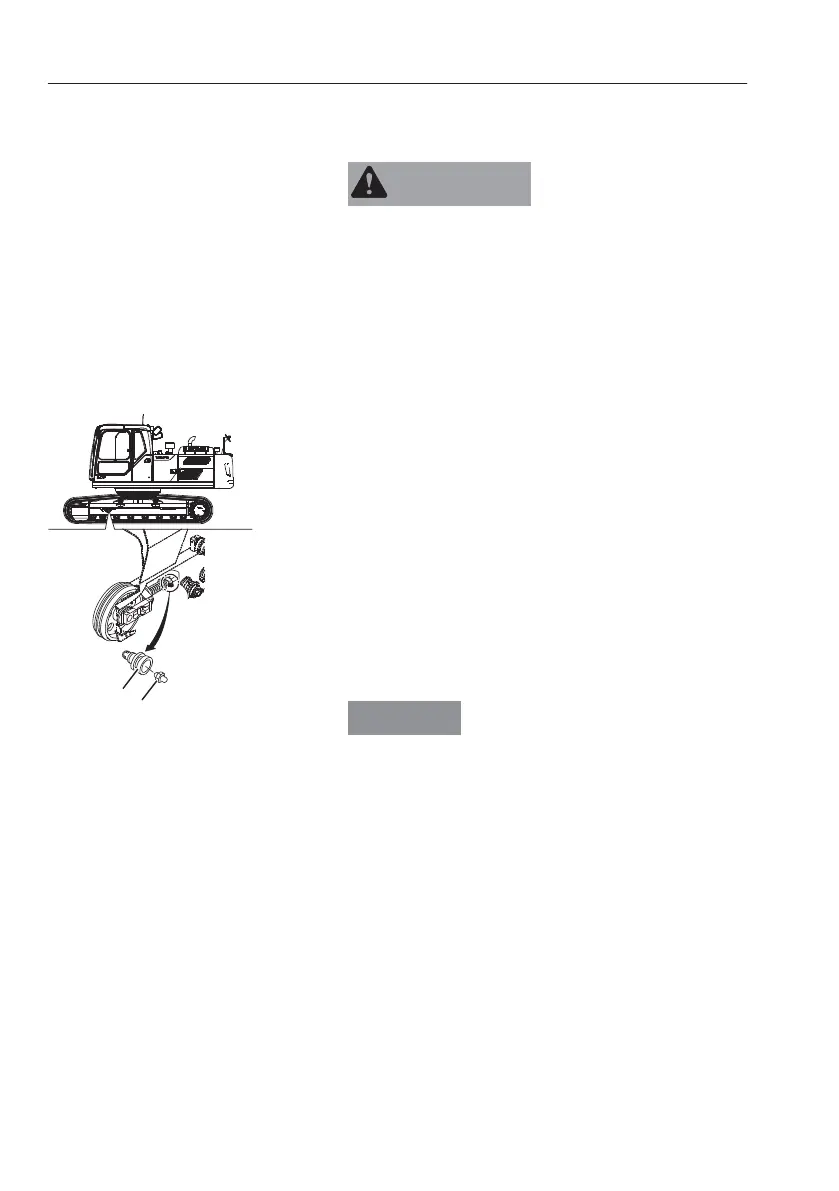

V1170104

A Valve

B Grease nippie

2

0

0

M

a

i

n

t

e

n

a

n

c

e

M

a

i

n

t

e

n

a

n

c

e

s

e

r

v

i

c

e

,

w

h

e

n

r

e

q

u

i

r

e

d

Loading...

Loading...