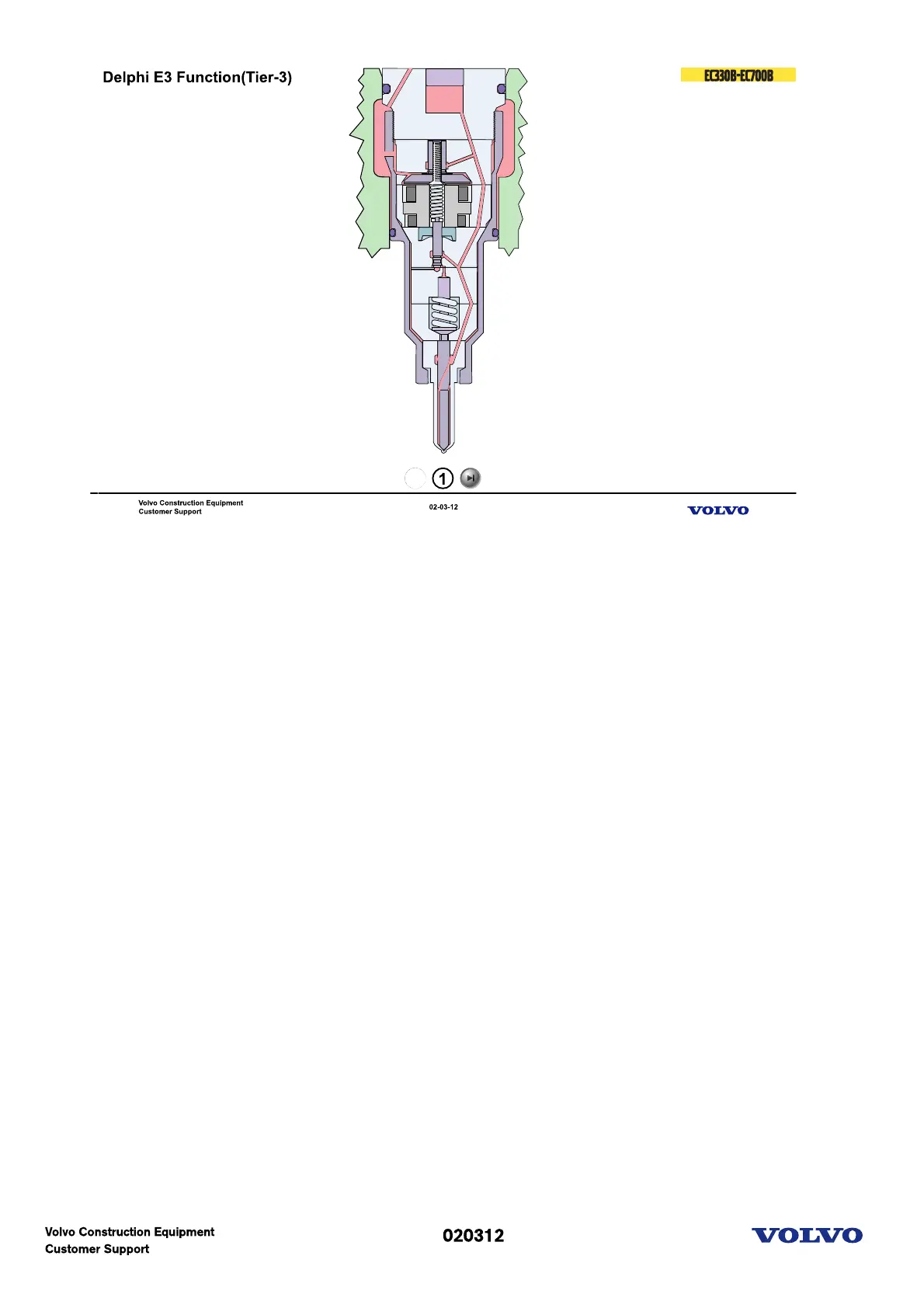

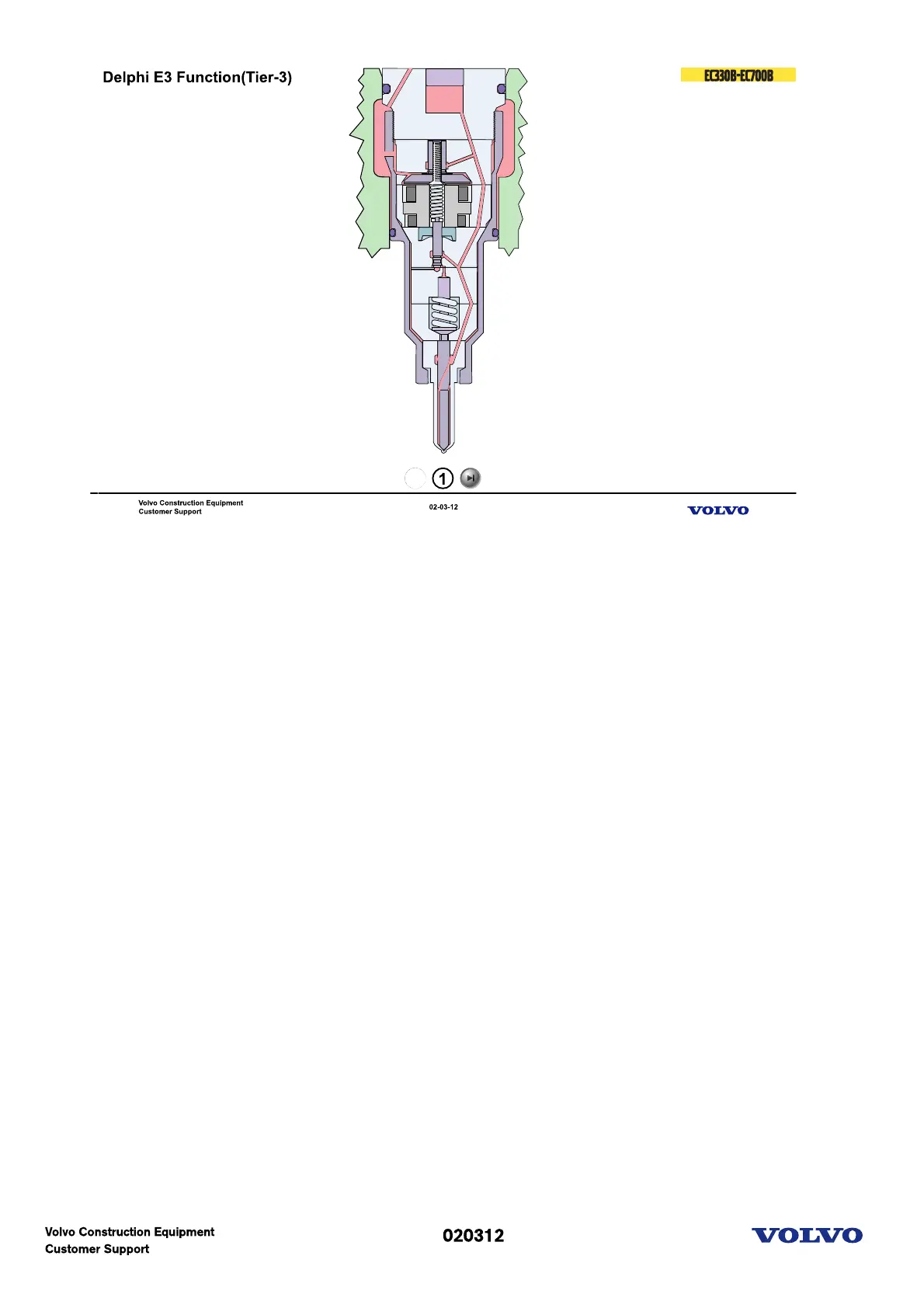

Delphi E3 function(Tier-3)

1. Neither the spill valve (SV) nor the needle control valve (NCV) solenoid is electrically activated. The

return spring is forcing the SV to its upper position and the NCV to its lower position. In this position the

SV is open and the fuel are routed from the pump chamber back into the low pressure fuel feed line and

no internal pressure build-up occurs in the high pressure fuel line. In this position the NCV is closed

connecting the needle backing chamber with the high pressure fuel line, but as the SV is open there is no

pressure build behind the needle.

2. The SV solenoid is electrically activated and the SV is pulled downwards closing the connection to the

low pressure feed line. In this position the SV is closed and all fuel is forced from the pump chamber via

the high pressure fuel line. The fuel pressure increases acting on the injection needle lift area. The NCV is

still not activated (still closed) connecting the needle backing chamber with the high pressure fuel line,

why the needle can not be lifted.

3. The SV is still closed and the fuel pressure is still increasing. When the desired pressure is achieved, the

NCV is activated (opened), closing the high-pressure line connection to the backing chamber of the needle

and at the same time connecting the chamber to the low pressure line. The pressure on the lift side, now

higher than required to overcome the closing force from the needle closing spring, opens the needle and

injection occurs until the NCV is closed or until the SV is opened.

In this way the needle opening pressure can be varied between the preset NOP of the spring and the

maximum pumping pressure. Practically the levels used are between 250 to 1800 bars, to be compared

with a common nozzle, using 250 to 350 bar opening pressure.

Picture text:

Loading...

Loading...