CAUTION!

Always use a new coupling element for reassem-

bling whenever male nut and plug have been dis-

connected.

Removing clips

10

5. Repairs

The components of VOSS

quick connect system 232 do

not wear or tear as a result of

operation.

Should any of the compo-

nents be damaged as a result

of inappropriate handling,

these may be replaced as

required.

5.1 Replacing the thread-

sealing o-ring

The old o-ring can be re-

moved when the system is

disconnected from the com-

ponent (see section 4.5).

Clean the groove in the cou-

pling element carefully and

check that it is not damaged.

The coupling element must be

replaced if there are any signs

of damage (see section 5.2).

Then replace the old o-ring

with a new one which has

been greased. All damage,

excess stretching or twisting

of the o-ring is to be avoided

when fitting.

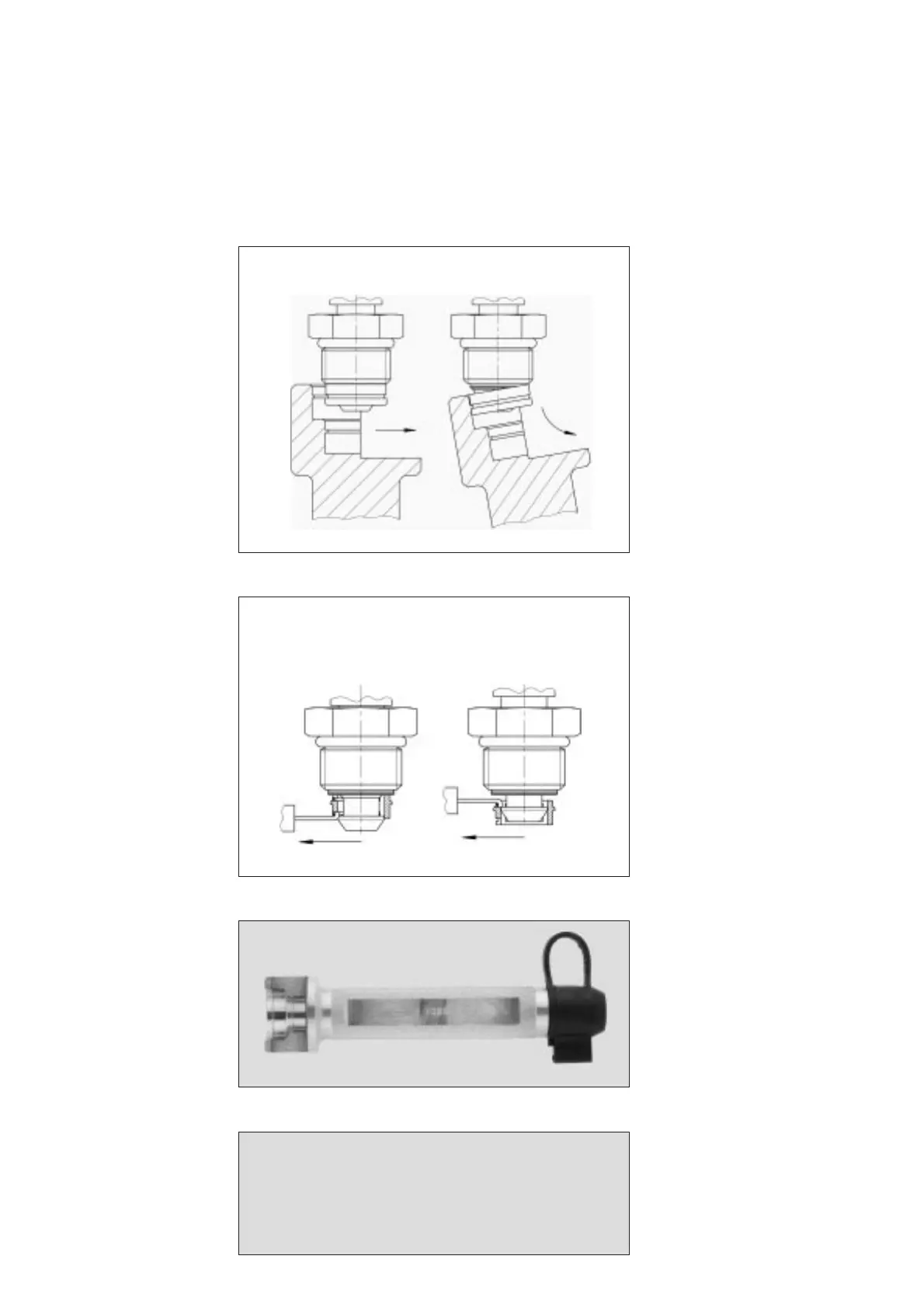

5.2 Disconnecting coupling

element

Break the connection (see

section 4.5) and lever off the

fixing ring using a suitable tool

(see fig. 1). Take care that the

plug is not damaged in this

process.

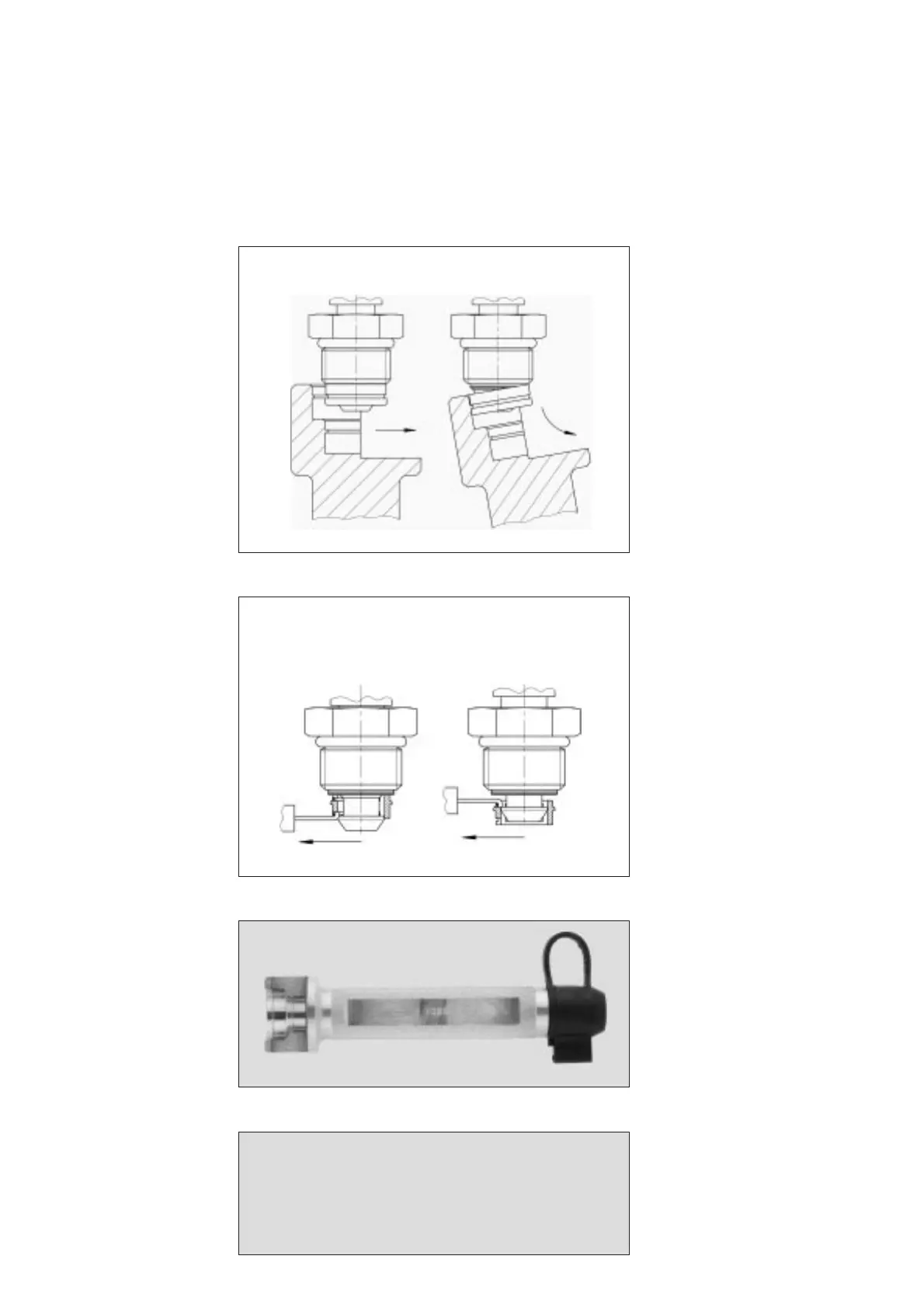

Then pull the clips sideways

out of the retaining ring. This

can be done by inserting a

pointed tool through the slot

in the cage behind the clips

(see fig. 2).

Once the two clips and the

retaining ring have been

removed, the plug may be

pulled out of the male nut.

A suitable disassembly tool is

available on request.

1. Slide disassembly

tool onto fixing ring

3. Insert disassembly

hook from below

and pull out first clip

sideways

To reassemble, always use a

new coupling element when-

ever the plug has been

removed from the male nut. In

addition, the o-rings for the

plug must be checked,

replaced if necessary and re-

greased.

5.3 Replacing plug o-rings

The damaged o-ring can be

removed after disconnection

(see section 5.2). Clean the

groove carefully, and then

replace the old o-ring with a

new one which has been

greased. All damage, excess

stretching or twisting of the o-

ring is to be avoided when

refitting. This applies both to

the sealing o-ring and to the

dirt-protection and pretension

o-ring.

5.4 Lubrication of the

o-rings

In order to ensure the functio-

nal reliability of the o-rings,

use only grease that has

been tested and approved by

VOSS.

Approved lubricating greases

are:

- Bechen – Berulub

Hydrohaf 2

- Bechen – Berulub

Hydrohaf GR

- Klüber – SYNTHESO

GLEP 1

Levering off fixing ring

VOSS Part No. 5 9 94 47 10 00 Fig. 3

Disassembly tool for the coupling element

2. Remove fixing ring

by levering

Fig. 1

4. Insert disassembly

hook from above and

pull out second clip

sideways

Fig. 2

Loading...

Loading...