ICON USER’S MANUAL: SECTION 8 VIRGINIA PANEL CORPORATION

6/7/18

8-6 For the most current information available, visit www.vpc.com.

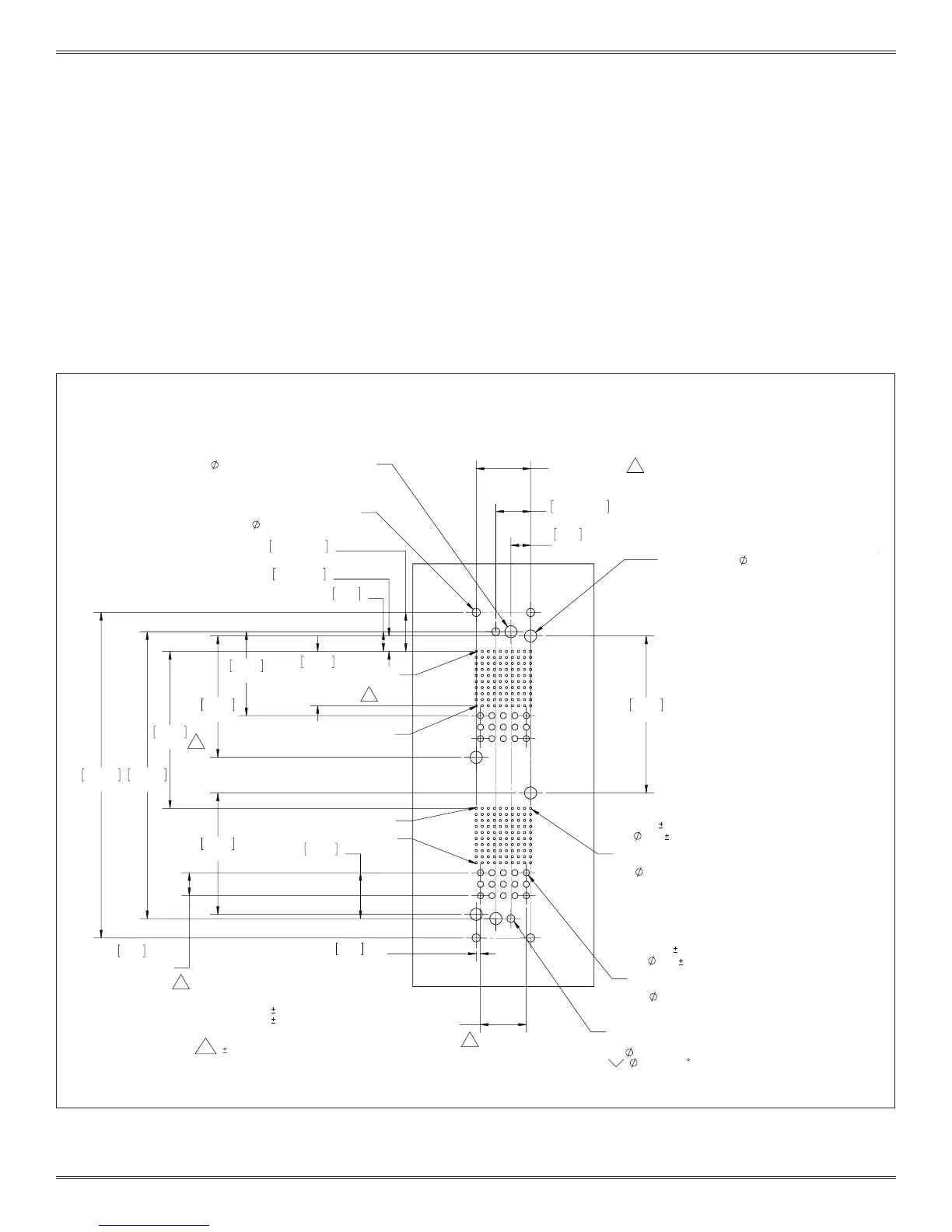

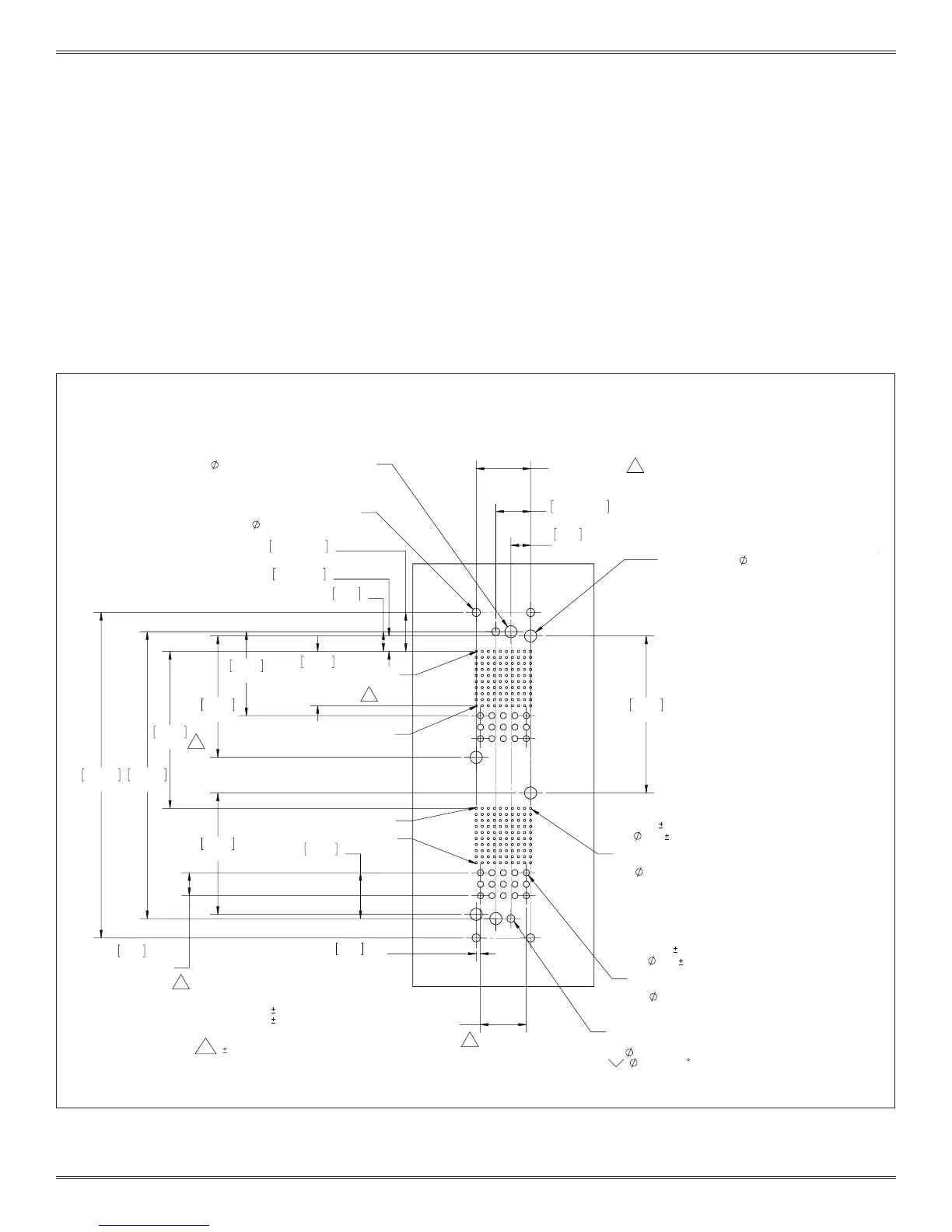

PCB layout for the iCon Receiver, Part # 310 123 101 loaded with two 510 160 112/113 modules. 200 thru

hole and pad diameters are for VPC QuadraPaddle Adapter Contact, Part #610 138 117; 30 thru hole

and pad diameters are for VPC Micro Power contact, Part # 610 142 102. The size of these holes may

be different if a header from a different manufacturer is used.

Also shown are optional clearance holes.

VPC modules/pin mount this side.

PCB LAYOUT AND MOUNTING

QUADRAPADDLE SIGNAL/MICRO POWER OR MICRO COAXIAL MODULE, RECEIVER,

ICON, 100/15 POSITION, WITH TWIN FEMALE SIGNAL • PART # 510 160 112

QUADRAPADDLE SIGNAL/MICRO POWER OR MICRO COAXIAL MODULE, RECEIVER,

ICON, 100/15 POSITION, FULLY LOADED WITH MALE POSTS • PART # 510 160 113

8.26

.325

TYP.

.900

9 PLCS. @ .100

TYP. 2 PATTERNS

[0.94

0.08]

.037 .003

PLATED THRU HOLE

[1.52]

.060 PAD

TYP .200 PLCS EACH

[2.54

0.08]

.100 .003

PLATED THRU HOLES

[3.18]

.125 PAD

TYP 30 PLCS EACH

.760

TYP.

4 PLCS. @ .190

TYP. 2 PATTERNS

9.65

.38

2 PLCS. @ .190

TYP. 2 PATTERNS

22.86

.90

9 PLCS. @ .100

TYP. 2 PATTERNS

CLEARANCE HOLES

FOR FRAME MOUNTING SCREWS

4 X

.135[3.43] THRU

8.26

.325

35.31

1.39

120.65

4.750

6.48±0.25

.255±.010

16.38±0.25

.645±.010

14.61±0.25

.575±.010

136.91

5.39

51.05

2.01

66.04

2.600

51.05

2.01

19.30

.76

1.78

.07

TYP.

66.04

2.60

3&%02817,1*+2/(686(6

;7+5($')/$7+($'6&5(:6

;

7+58$//

;

)$56,'(237,21$/

CLEARANCE HOLES

FOR ACCESS TO KEYING FEATURE MOUNTING SCREWS

2 X

.200[5.08] THRU

CLEARANCE HOLES

FOR ACCESS TO MODULE MOUNTING SCREWS

4 X

.200[5.08] THRU

PIN A1

PIN A10

PIN A1

PIN A10

RECOMMENDED PCB LAYOUT

CONNECTOR MOUNTS THIS SIDE

TOLERANCES ARE:

.XX=

[0.25] .01

.XXX=

[0.13] .005

UNLESS OTHERWISE SPECIFIED

1

.0021 LOCATION TOLERANCE

APPLIES TO PLATED THRU HOLES

TOLERANCE N0N-ACCUMULATIVE

1

1

1

1

1

Loading...

Loading...