ICON USER’S MANUAL: SECTION 3 VIRGINIA PANEL CORPORATION

3-1 For the most current information available, visit www.vpc.com.

6/7/18

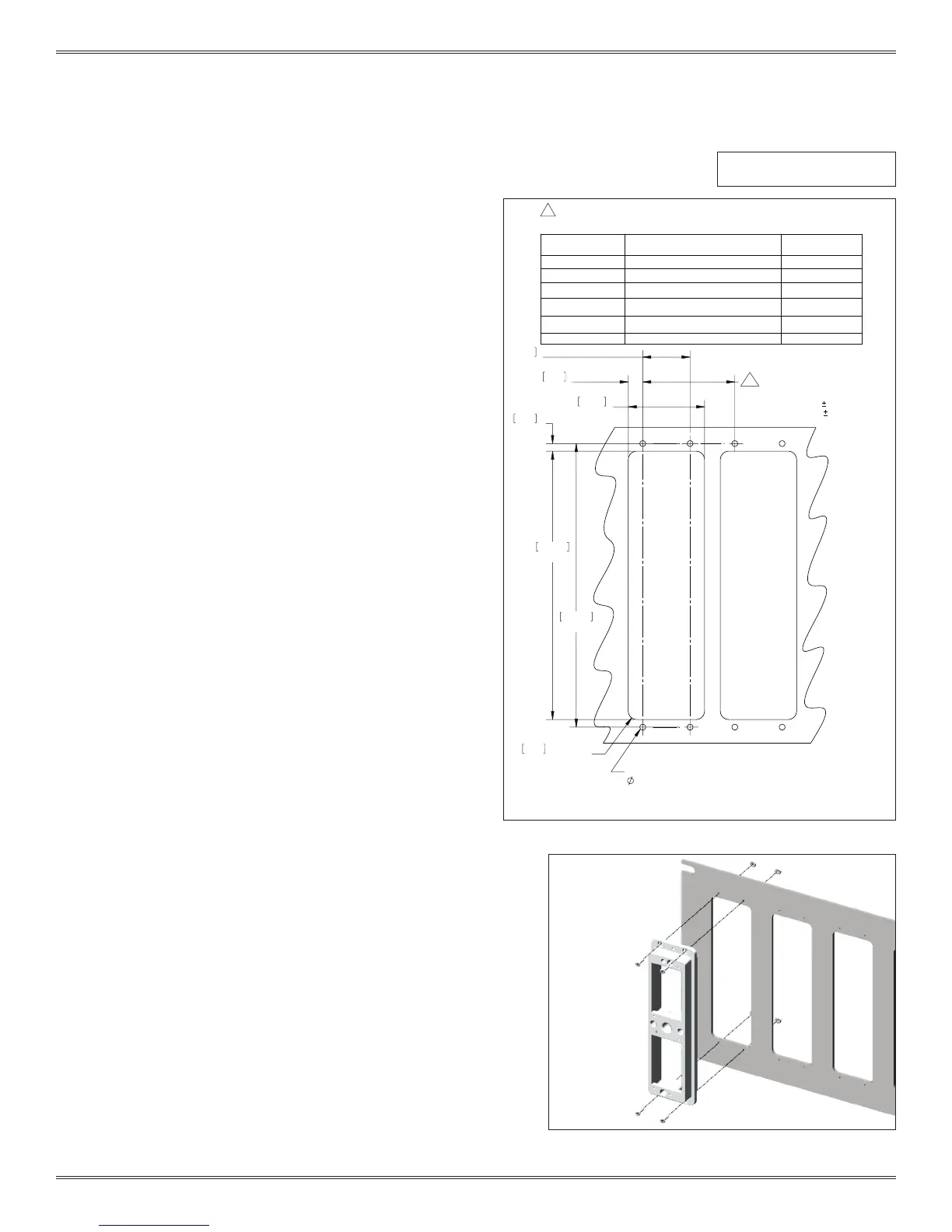

ICON RECEIVER MOUNTING

PART # 310 123 101

5.10

129.54

5.39

136.91

.90

22.86

1.45

36.83

.28

6.99

.15

3.68

R

.16

MAX TYP.

4.06

5.

RECOMMENDED PANEL

CUTOUT

TOLERANCES ARE:

.XX =

.01[.25]

.XXX =

.005[.13]

UNLESS OTHERWISE SPECIFIED

FOR MOUNTING USE

[2.79].11 THRU HOLE,

2-56 OR M2.5 METRIC

TAPPED HOLE

(SUPPLIED WITH 4X, 2-56 SCREWS,

LOCK WASHERS & NUTS)

5

SEE TABLE 1 FOR MINIMUM DISTANCE OF SUBSEQUENT SIDE BY SIDE CUTOUTS.

TABLE 1

PART NUMBER

DESCRIPTION

RECEIVER CUTOUT

SPACING

410123101

ITA, iCon

1.75 [44.45]

410123102

ITA, iCon, EMI-Shielded

2.20 [55.88]

410123106

ITA, iCon, with Large Cable Clamp

2.20 [55.88]

410123111

ITA, iCon, with Threaded Coupling

Adapter

2.20 [55.88]

410123116

ITA, iCon, with Large Cable Clamp,

with EMI Housing and Handle

2.20 [55.88]

410123122

ITA, iCon with Oversized Backshell

2.20 [55.88]

TOOLS REQUIRED

Phillips Head Screwdriver

MOUNTING INSTRUCTIONS

1. Prepare the mounting surface using the dimensions

provided in Figure A.

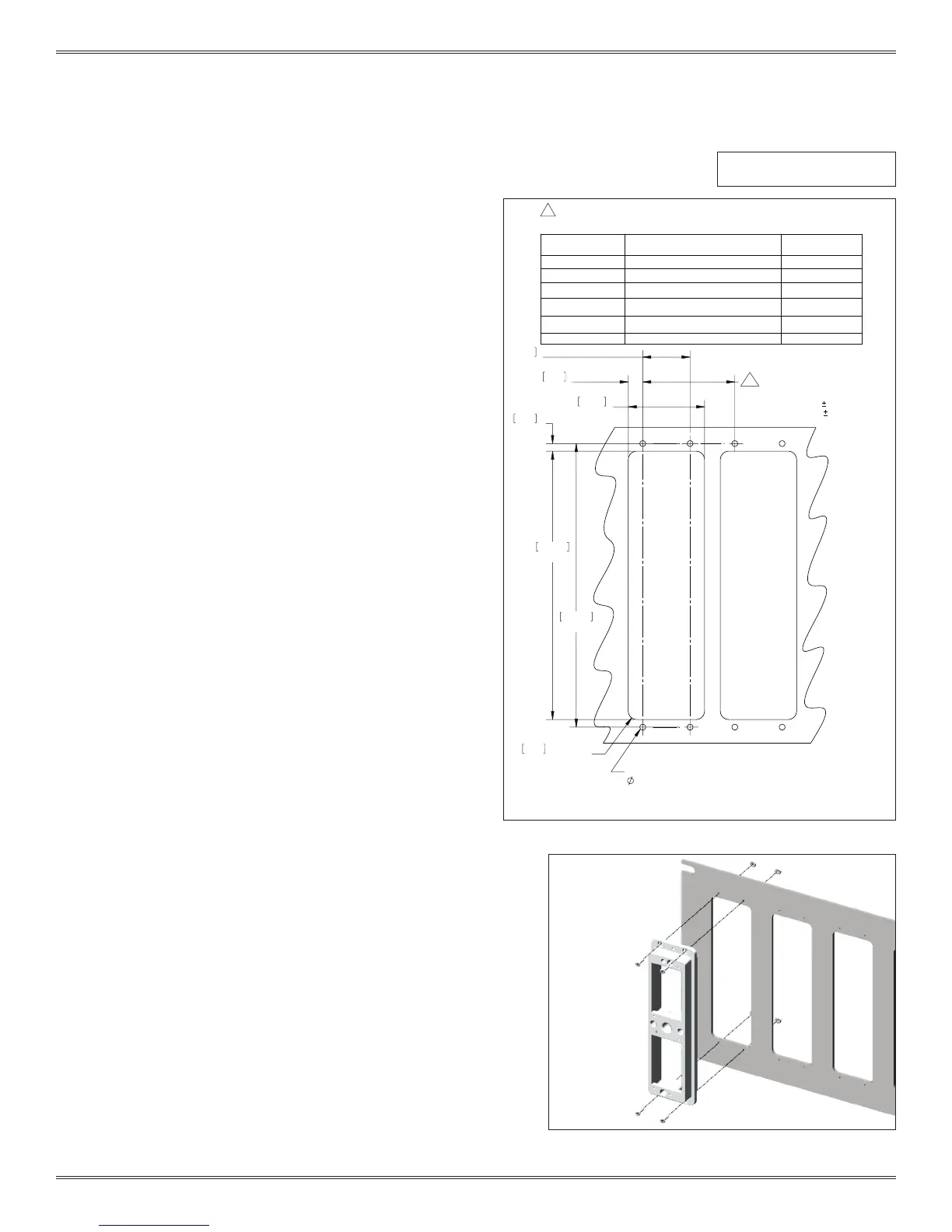

2. Attach the iCon receiver to the panel with the provided

2-56 Phillips head screws and nuts (Figure B). Torque

screws to 2 in-lbs [0.23 Nm].

NOTE: If the mounting surface is thicker than 0.125” [3.18

mm], longer screws may be needed.

NOTE: If the mounting surface has threaded holes, the

nuts will not be needed.

NOTE: M2.5 hardware can be used in place of the

provided 2-56 hardware.

Figure A. Recommended panel cutout.

Figure B. If you prefer metric hardware, you can replace

the supplied 2-56 screws with M2.5 hardware.

Dimensions shown: [millimeters]

inches

Loading...

Loading...