VRG CONTROLS LLC. 12 of 60 JUNE 2021

VPC “BV” SERIES VALVE PILOT CONTROLLERS

INSTRUCTION MANUAL

VRG Controls LLC. 12 of 54 APRIL 21, 2019

NOTES

1. Adjustment and Installaon of VRG Controls equipment should be only

be performed by qualied personnel adequately trained and familiar with

products.

2. For technical assistance, please contact your local VRG Controls Sales

Representave or VRG Controls direct (www.vrgcontrols.com).

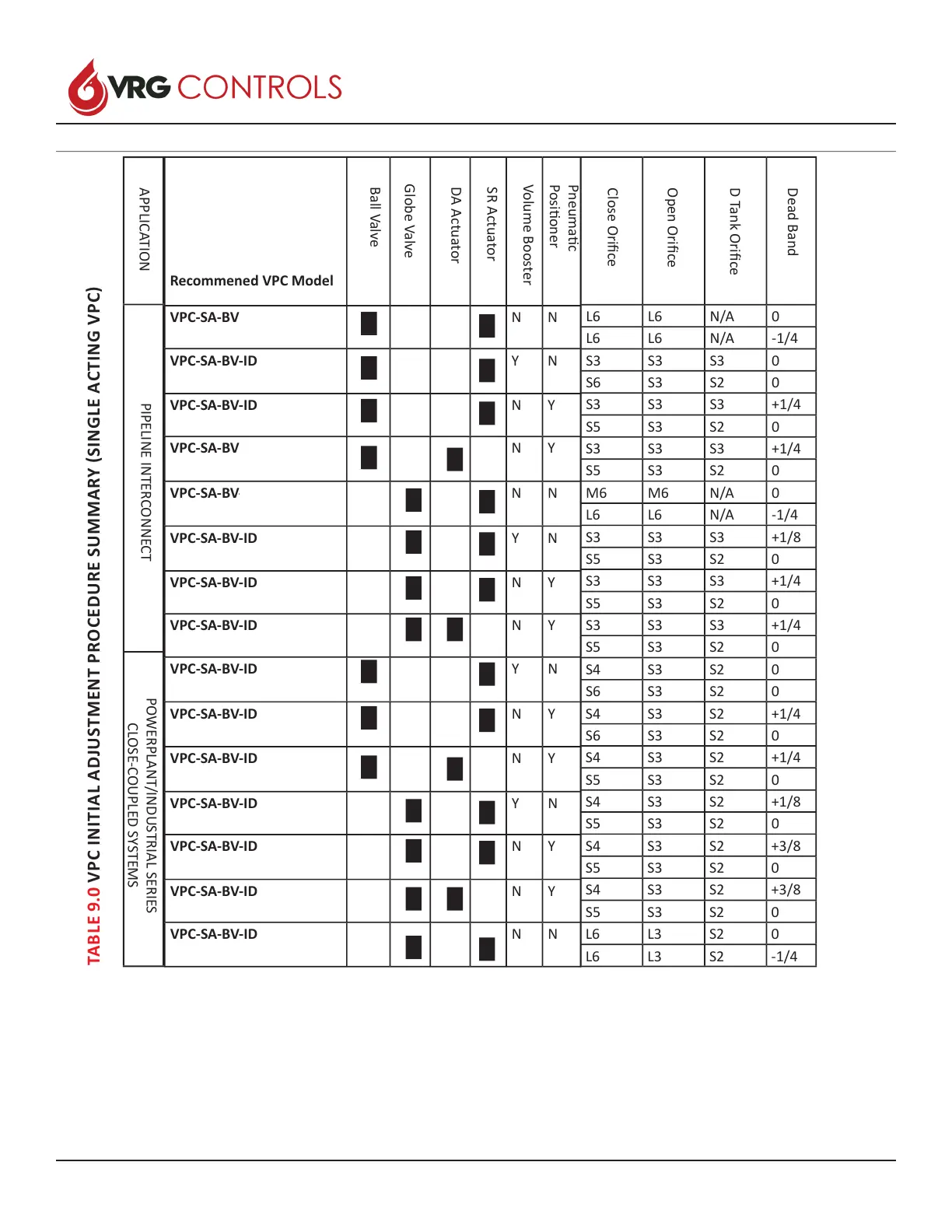

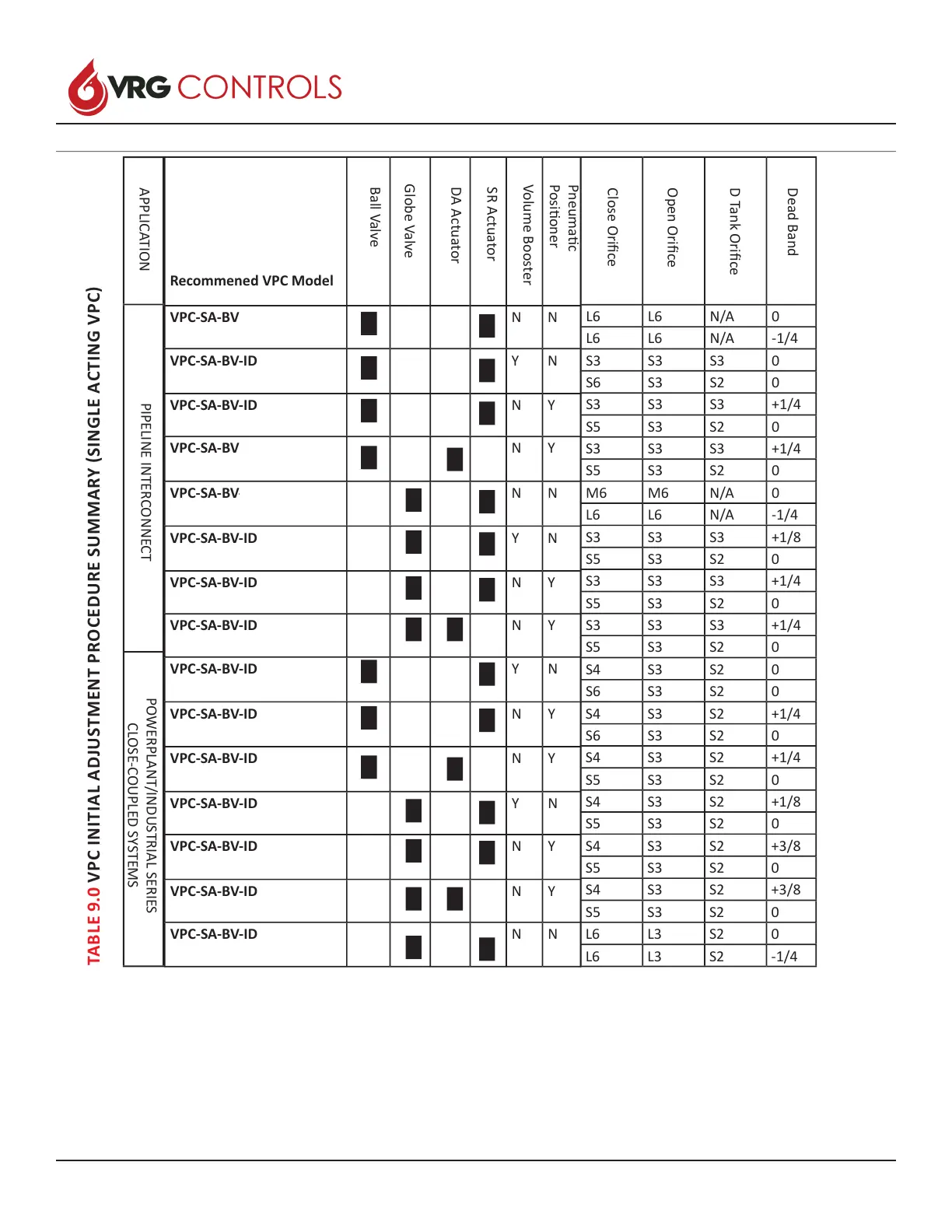

3. All values represent a starng point. Dynamic tuning with VPC in “live

control” will be necessary to opmize performance.

4. In this table, Pipeline Interconnects are dened >1.0 mile downstream

piping adjacent to control valve.

5. In this table, Close-Coupled System Applicaons are dened <1.0 mile

downstream piping adjacent to control valve.

6. Increasing number on the SUPPLY & EXHAUST ORIFICE will increase

the speed of response independently in each direcon (faster reset rate).

Refer to VPC Applicaon Schemac to determine which Adjustable Orice

controls OPEN and CLOSE speed.

7. Increasing number on the “D” TANK ORIFICE will introduces a DERIVATIVE

funcon controls the RATE of OUTPUT. Larger DERIVATIVE number of “D”

TANK Adjustable Orice introduces more dampening of the OUTPUT.

8. If stable control is achieved upon adjusng the VPC per the above

guidelines, the deadband may be reduced (smaller number on Sensivity

Adjusng Drum). For dynamic systems, do not reduce deadband to less

than “ZERO” as dened in Inial Adjustment Procedures.

9. If system is unstable upon adjusng VPC per above guidelines, correcve

adjustment to INCREASE CLOSING speed and REDUCE OPENING speed are

suggested. Addionally, the deadband may be increased (larger number on

Sensivity Adjusng Drum).

10. Top row - Worker // Boom Row - Monitor

TABLE 9.0 VPC INITIAL ADJUSTMENT PROCEDURE SUMMARY (SINGLE ACTING VPC)

Recommened VPC Model

VPC-SA-BV N N

VPC-SA-BV-ID Y N

VPC-SA-BV-ID N Y

VPC-SA-BV N Y

VPC-SA-BV-ID N N

VPC-SA-BV-ID Y N

VPC-SA-BV-ID N Y

VPC-SA-BV-ID N Y

VPC-SA-BV-ID Y N

VPC-SA-BV-ID N Y

VPC-SA-BV-ID N Y

VPC-SA-BV-ID Y N

VPC-SA-BV-ID N Y

VPC-SA-BV-ID N Y

VPC-SA-BV-ID N N

L6 L6 N/A 0

L6 L6 N/A -1/4

S3 S3 S3 0

S6 S3 S2 0

S3 S3 S3 +1/4

S5 S3 S2 0

S3 S3 S3 +1/4

S5 S3 S2 0

M6 M6 N/A 0

L6 L6 N/A -1/4

S3 S3 S3 +1/8

S5 S3 S2 0

S3 S3 S3 +1/4

S5 S3 S2 0

S3 S3 S3 +1/4

S5 S3 S2 0

S4 S3 S2 0

S6 S3 S2 0

S4 S3 S2 +1/4

S6 S3 S2 0

S4 S3 S2 +1/4

S5 S3 S2 0

S4 S3 S2 +1/8

S5 S3 S2 0

S4 S3 S2 +3/8

S5 S3 S2 0

S4 S3 S2 +3/8

S5 S3 S2 0

L6 L3 S2 0

L6 L3 S2 -1/4

Ball Valve

Globe Valve

DA Actuator

SR Actuator

Volume Booster

Pneumac

Posioner

Close Orice

Open Orice

D Tank Orice

Dead Band

APPLICATION

PIPELINE INTERCONNECT

POWERPLANT/INDUSTRIAL SERIES

CLOSE-COUPLED SYSTEMS

Loading...

Loading...