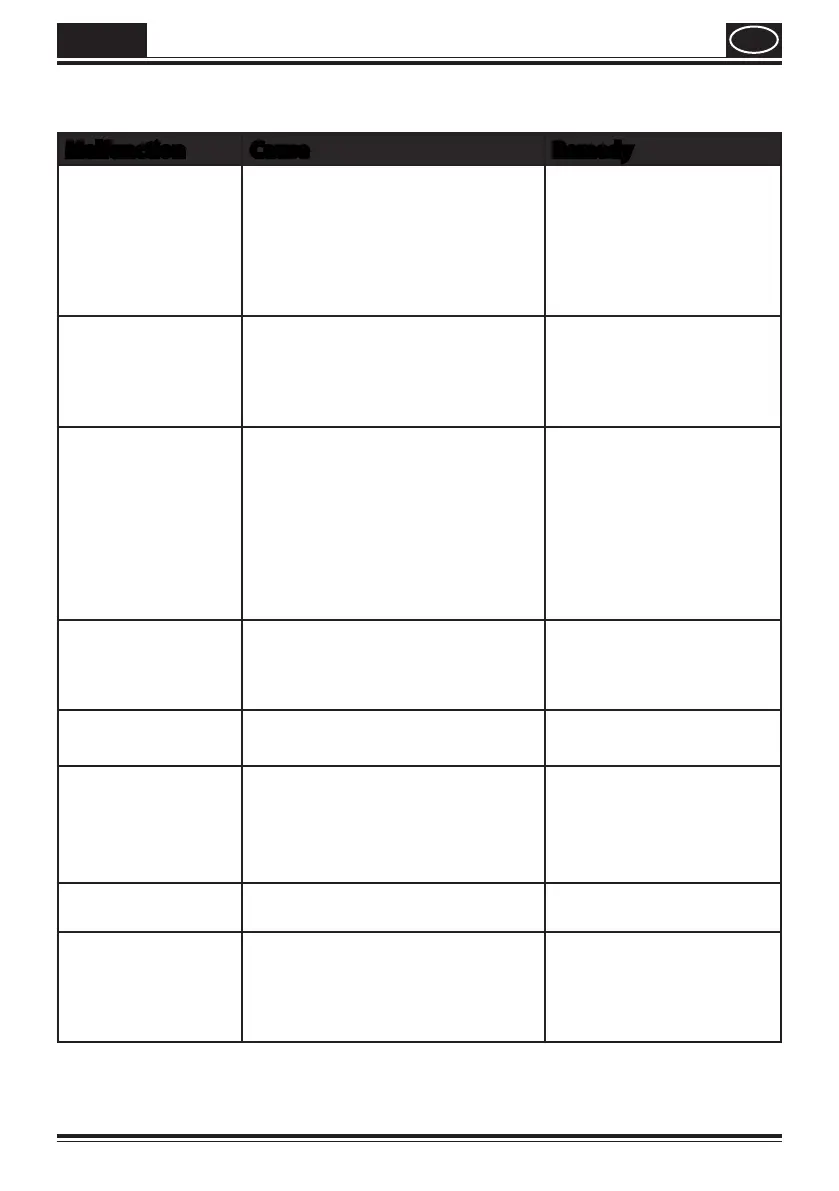

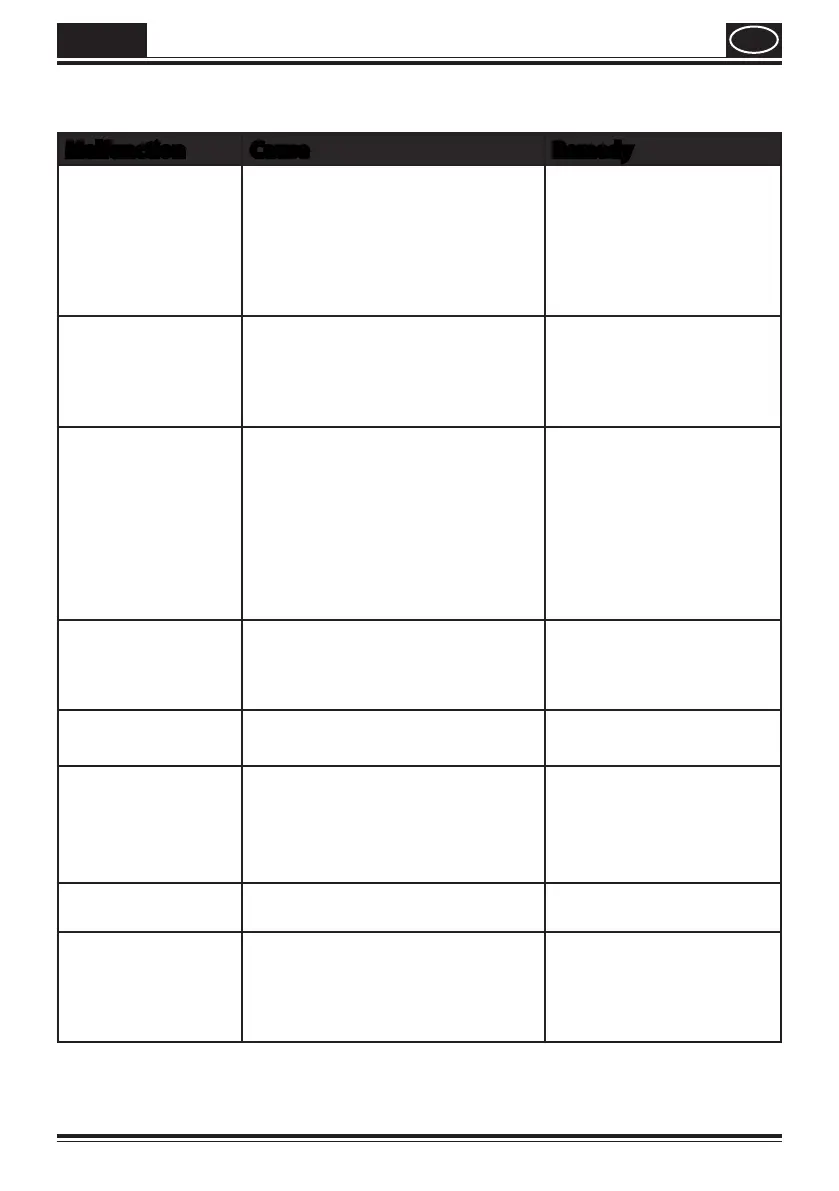

Correction of Malfunctions

Malfunction Cause Remedy

No coating material

emerges from the

nozzle

Nozzle clogged

Material volume setting turned too far

to the left (-)

No pressure build-up in container

Container empty

Feed tube loose

Feed tube clogged

Clean

Turn to the right (+)

Tighten container

Rell

Insert

Clean

Coating material drips

from the nozzle

Coating material assembly at air cap,

nozzle or needle

Nozzle loose

Nozzle seal worn

Nozzle worn

Clean

Union nut tighten

Change

Change

Atomisation too coarse Material volume too large

Material volume adjusting screw turned

too far to the right (+)

Nozzle contaminated

Viscosity of coating material too high

Too little pressure build-up in container

Air lter heavily soiled

Amount of air too low

Turn material volume adjusting

screw to the left (-)

Clean

Add 5 - 10% dilution

Tighten container

Change

Turn the air volume control to

the right (+)

Spray jet pulsates Coating material in container running

out

Nozzle seal worn

Air lter heavily soiled

Rell

Replace

Change

Coating material causes

"paint tears"

Too much coating material applied. Turn material volume adjusting

screw to the left (-)

Too much fog of

coating material

(Overspray)

Distance to the object too large

Too much coating material applied

Amount of air too high

Reduce distance

Turn material volume adjusting

screw to the left (-)

Turn the air volume control to

the left (-)

Paint in the ventilating

hose

Diaphragm soiled

Diaphragm defective

Clean the diaphragm

Replace the diaphragm

Device does not

function

Device overheated Unplug the power plug, let

the device cool down approx.

30 minutes, do not bend the

hose, check the air lter, do not

cover the intake slots

Stör GB

Loading...

Loading...