• Press the spool down GENTLY and rotate it until you feel it drop into place. (When in place, the spool

will turn a few degrees left and right freely.)

• Snap the spool cover back on, insert the battery and turn the tool on. In a few seconds you’ll hear the

nylon line being cut automatically to the proper length.

STORAGE & TRANSPORTATION

STORAGE

Store the tool in a dry and well-ventilated place.

TRANSPORTATION

Always remove the battery from the machine when transporting the product.

TROUBLE SHOOTING

Switch off the trimmer and disconnect the battery before inspecting, cleaning or working on the thread.

Nylon Line breaks too frequently

Nylon line too dry or brittle

Place the coil in a container with

water for approx. 24 hours. Dry

Nylon line in contact with fence

posts, trees, etc.

Use plant guard

Tilt switch is not working.

Dirt and debris in spool drive

mechanism.

Clean parts with a brush

Line is torn and stuck inside spool

Remove spool, check tightness of

winding and replace spool in the

Line is welded to itself or to spool

through heat build-up.

Remove welded line section,

check tightness of winding and

replace spool in the usual way.

If you can’t fix the fault yourself, contact your retailer. Please be aware that any improper repairs will also

invalidate the warranty and additional costs may be incurred.

CLEANING & MAINTENANCE

DANGER

Prior to conducting maintenance or cleaning: Remove the battery from the machine.

The trimmer continues to spin after being switched off!

Always remove battery before performing any work on the trimmer!

Note: Clean unit immediately after. Grass debris when dry is very hard and difficult to remove.

CLEANING

• Do not at any time let brake fluids, petrol, petroleum based products, penetrating oils, etc., come in

contact with plastic parts. They contain chemicals that can damage, weaken or destroy plastic.

• Make sure the battery is detached from the unit, then use only mild soap and a damp cloth to clean

the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

• Fertilizers and other garden chemicals contain agents which greatly accelerate the corrosion of

metals Do not store the tool on or adjacent to fertilizers or chemicals.

BEFORE EACH USE

Check the battery, charger and machine for

damage.

Conduct a visual inspection and have any faulty

component replaced.

Wipe the unit with a damp cloth.

Replace the nylon line if it is too short.

Replace the nylon line (1.6mm) and feed following

the directional arrow on the spool or replace with

replacement spool and line.

REPLACING SPOOL / CLEARING JAMS AND TANGLED LINES

From time to time, especially when cutting thick or stocky weeds, the line feeding hub may become

clogged with sap or other material and the line will become jammed as a result. To clear the jam, follow

these steps.

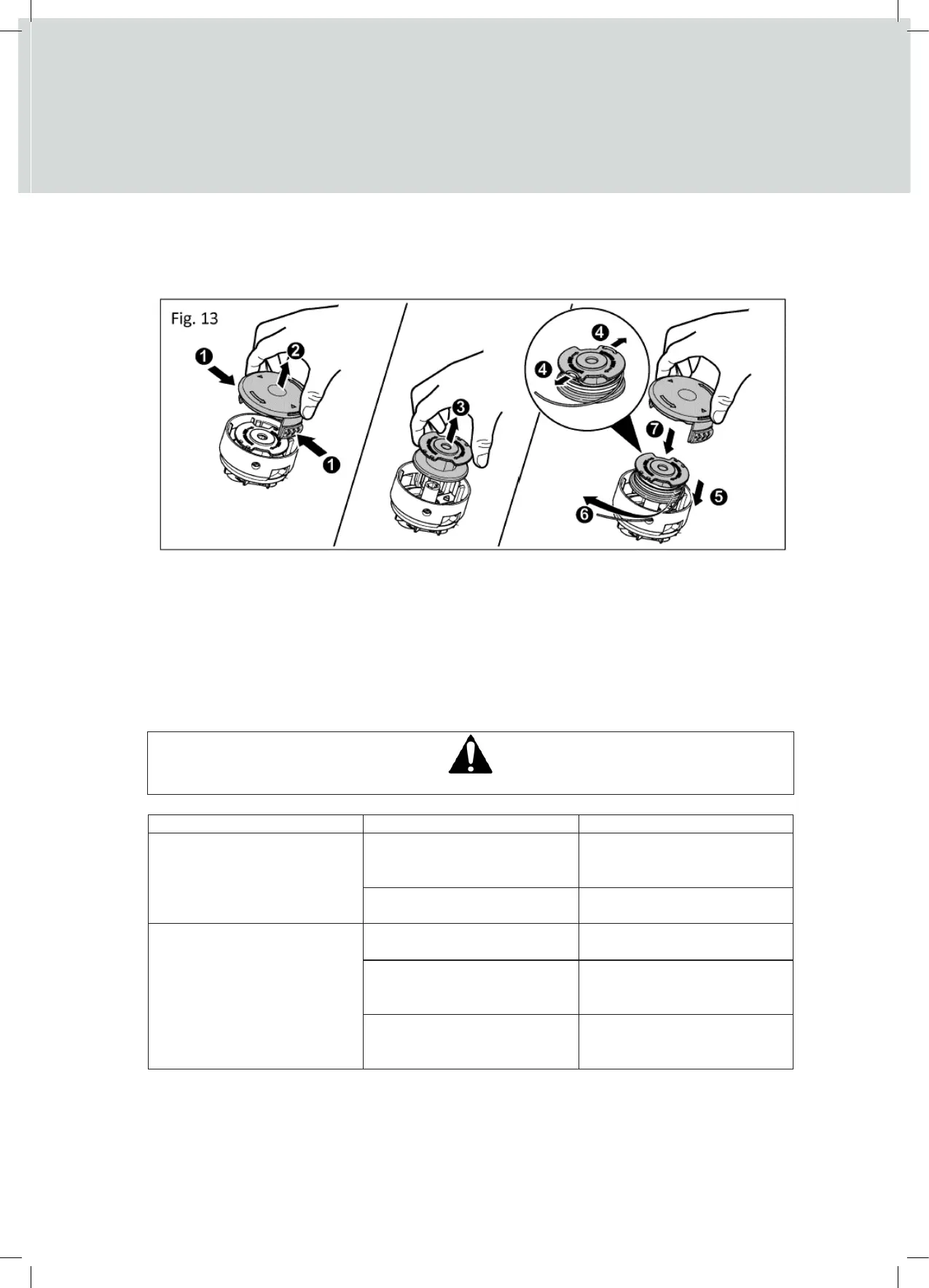

• Turn off the trimmer and remove the battery.

• Press the release tabs on the line spool retainer (1) and remove the cover (2) by pulling it straight off.

• Remove the line spool (3). If necessary, remove any dirt.

• Extend the line jammed or tangled out of the spool fitting (4).

• Insert the spool in the line receptacle (5).

• Thread the end of the line through the eyelet of the spool retainer (6).

• Firmly press both tabs of the spool cover together at the same time and push the cap onto the spool

until it engages.

REWINDING SPOOL FROM BULK LINE (USE ONLY 1.6MM DIAMETER LINE)

Bulk line for your trimmer/edger is available at extra cost from your local dealer. To install bulk line,

follow these steps:

• Turn off the trimmer and remove the battery.

• Press the release tabs on the line spool cover as shown in Fig. 11 and remove the cover by pulling it

straight off. Remove the spool from the tool and remove and discard all line on the spool.

• Insert one end of the bulk line into the hole in the spool.

• Hold the line in the hole and pull the rest of the line through the slot in the spool.

• Snugly and evenly wind the bulk line onto the spool in the direction of the arrow until it is nearly full.

• Insert the line end through the eyelet in the spool hub. Pull the line through the hole to maintain

tension while placing the spool down into the hub with the notched side exposed.

Loading...

Loading...