It is recommended that a bleed valve be installed in the discharge line, or in a line from the vent port to the

reservoir. This will allow the pressure in the pump to be relieved for service.

Installing a bleed valve is especially necessary in hot water application to prevent injury.

Pipe, valves and fittings must have a pressure rating equal to or greater than the maximum system pressure.

A bypass or pressure relief valve should be installed in the discharge line if there is any possibility the pump may

operate against a closed valve in the discharge line.

Minimum flow is required for proper cooling and lubrication of the pump. Operating below the following mini-

mum pumping rates could cause damage and premature failure could occur.

Make sure that the system is properly installed and primed as instructed in the installation section.

Check that the suction valve is fully open and the discharge valve is in the open position.

Check to make sure all electric connections are correct.

Apply power to the motor.

Check motor rotation. Shaft rotation must be counter-clockwise when viewed from back of motor. On 3 phase

motors, if the rotation is not correct reverse any two leads to the starter. The rotation will now be correct.

Check that the noise, vibration, pressure, voltage and amps are at normal levels.

Operation

Caution: Prolonged operation of the NV Series pump with either valve in the closed position will cause

severe damage to the pump.

Warning: Webtrol NV Series pumps are designed for continuos and normal on/off operation.

Rapid cycling can cause high heat and loading that can cause damage to the pump or motor.

- 7 -

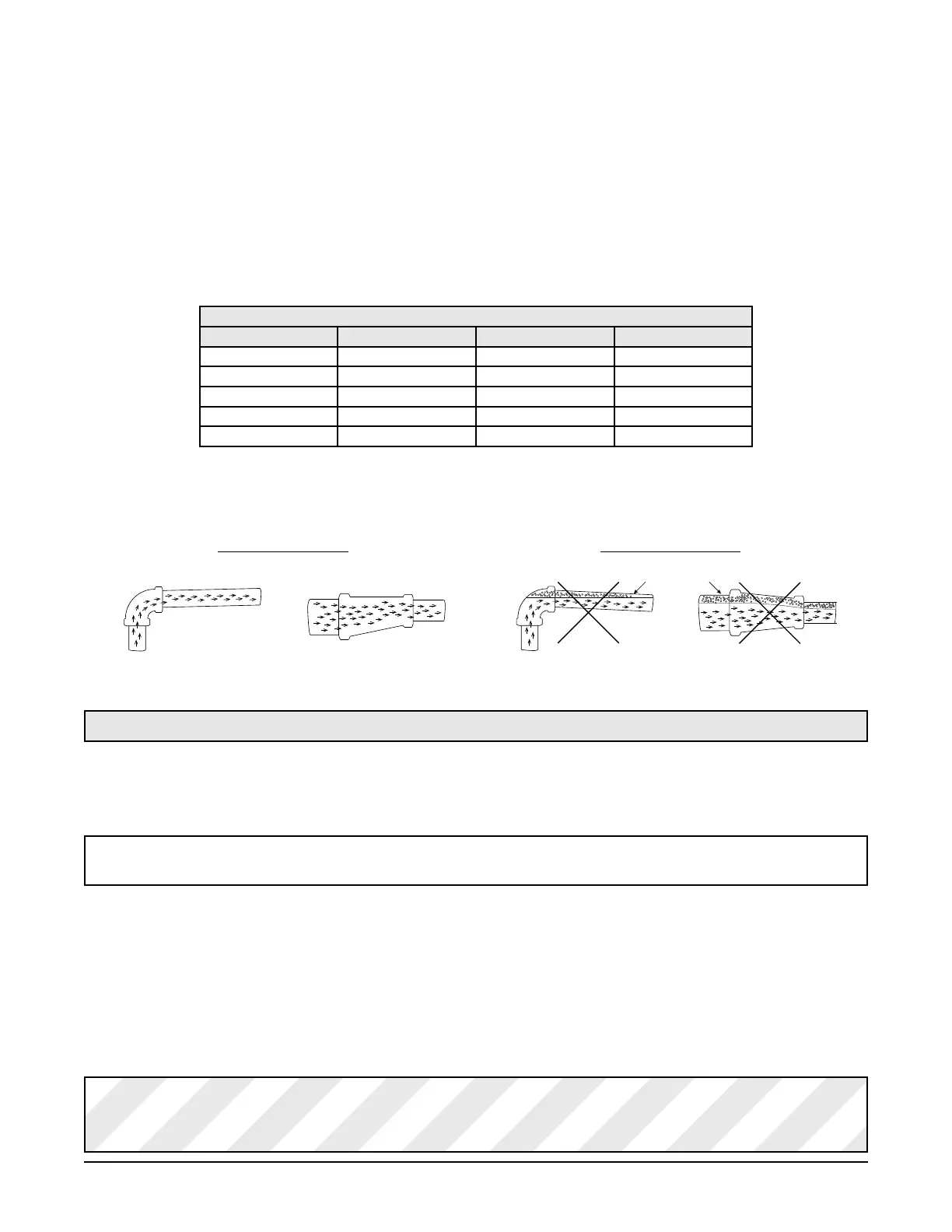

Minimum Pumping Rate

Series Flow Rate Series Flow Rate

NV6 2 GPM NV85 20 GPM

NV12 4 GPM NV120 30 GPM

NV25 7.5 GPM NV180 30 GPM

NV45 10 GPM NV280 50 GPM

NV65 10 GPM NV400 100 GPM

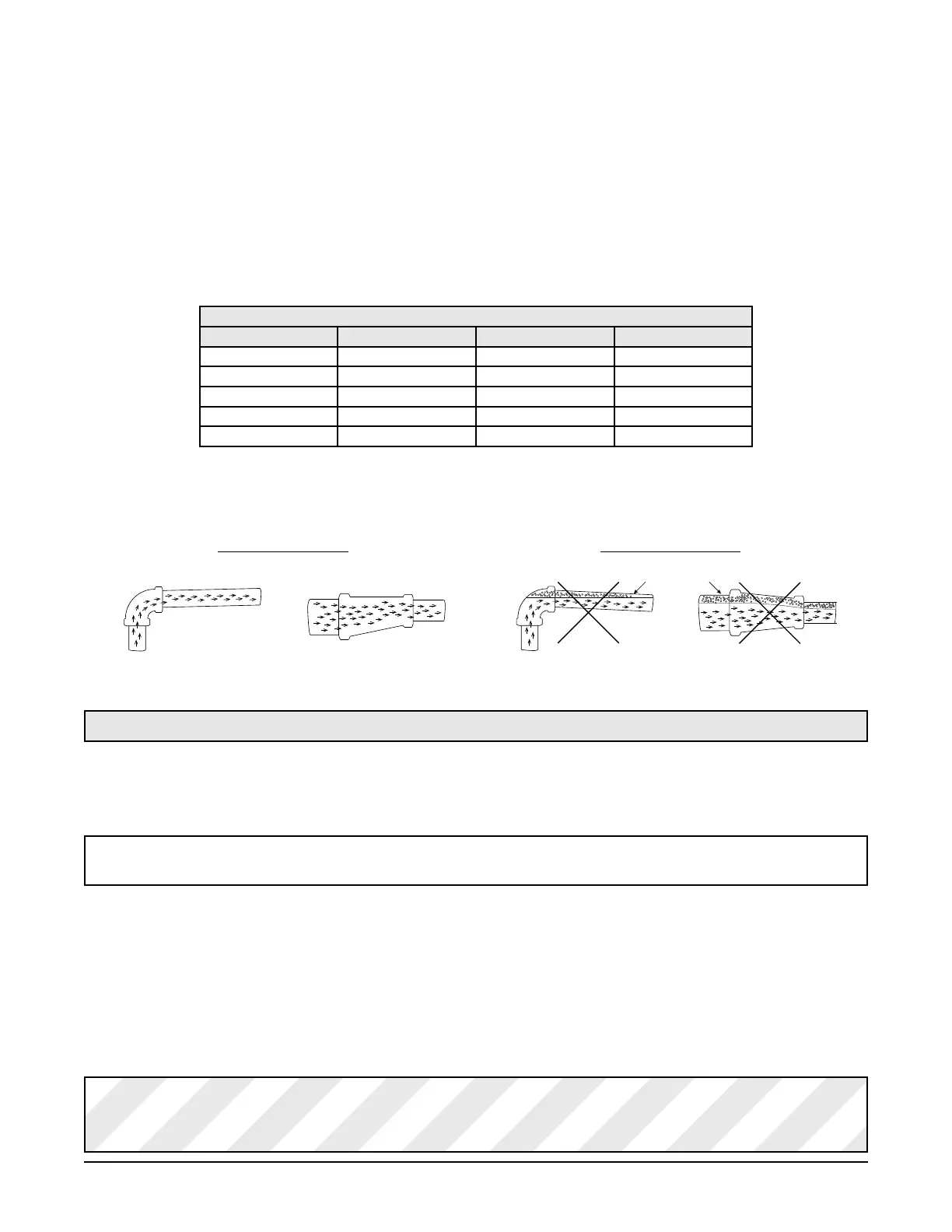

Suction Pipe Sloping Down Suction Pipe Belled Down

Air Pockets

To avoid damage to the pump, make sure on the suction side of the pump that there are no airlocks in the

system. The suction pipe should be level or slightly rising.

Correct Installation

Incorrect Installation

Suction Pipe Sloping Up Suction Pipe Belled Down

Loading...

Loading...