Weichai America Corp.

Revision: October 2018 19

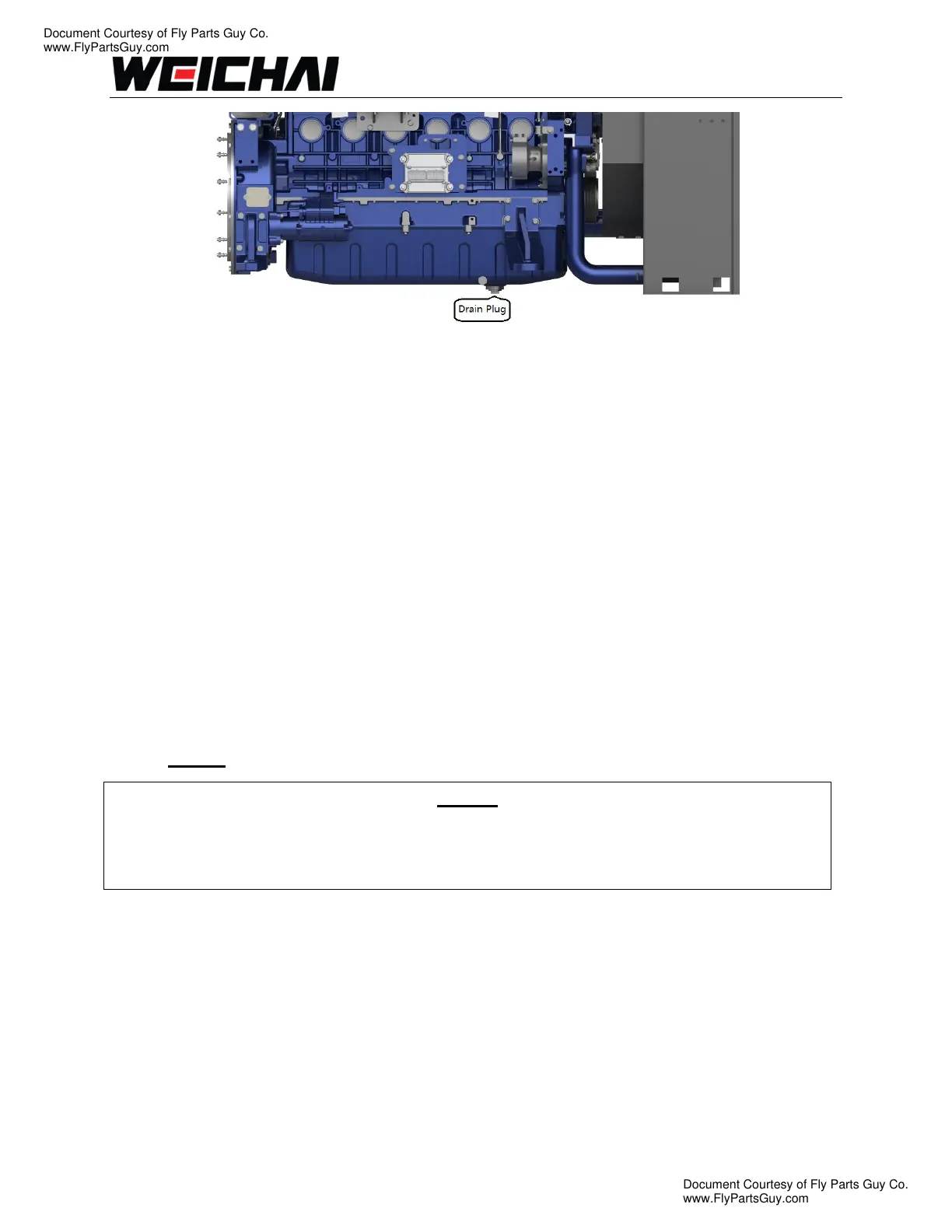

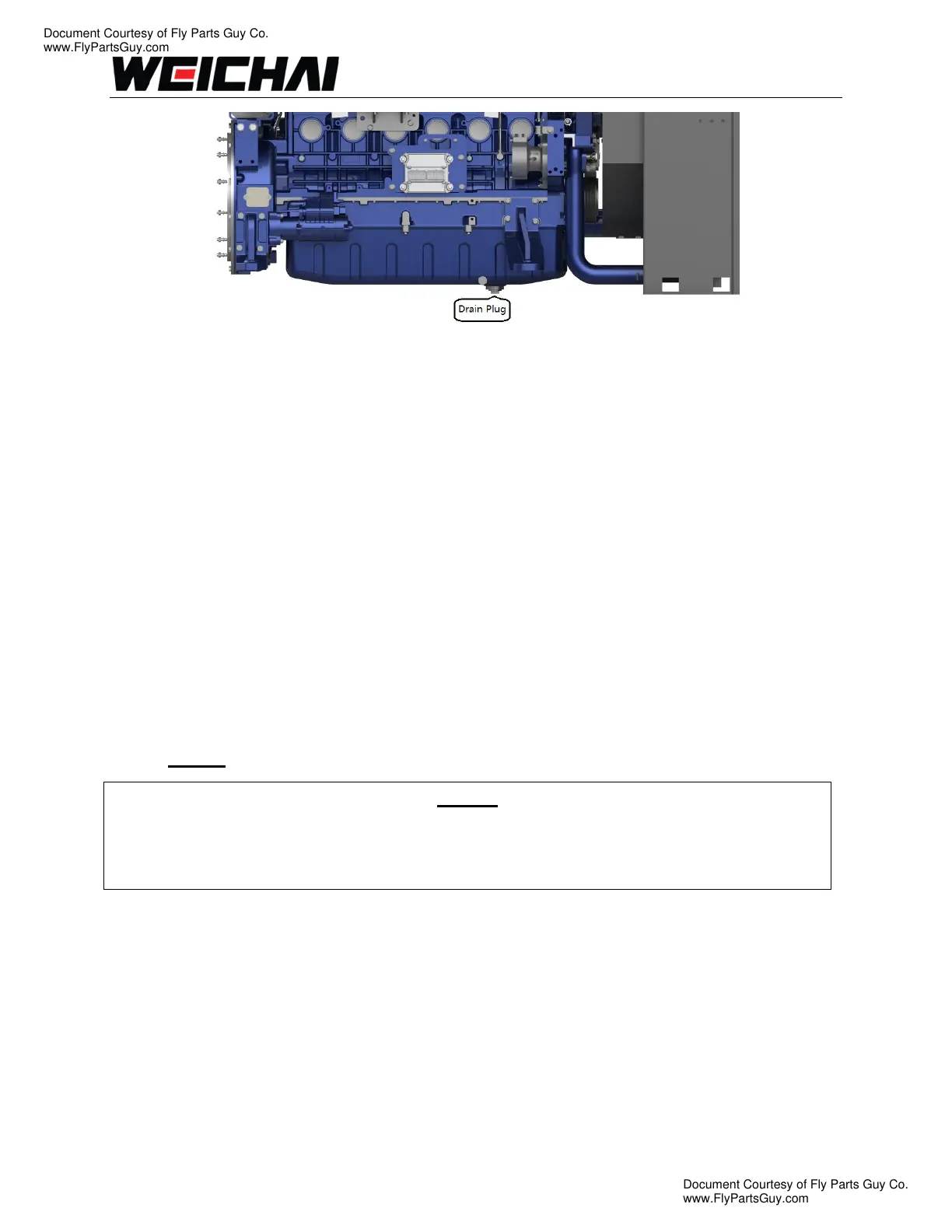

B. Inspect drain plug gasket (replace if necessary) and clean plug seating surface.

C. Inspect magnetic plug for iron and ferrous material. If this exists, consider an oil

analysis to determine source of debris.

D. Reinstall drain plug and tighten securely.

E. Remove the old filters by the filter wrench. Wipe filter base clean. Then apply a

thin coat of motor oil to o- ring on new oil filter(s).

F. Install oil filter. Tighten filter until the rubber gasket contacts base. Tighten

additional 3/4 to 1 turn to seal.

G. Using the recommended grade of oil, fill crankcase with specified quantity.

H. Fill the grease cup of the signal generator with lithium grease (NLGI Gr. 2).

I. Operate engine for five (5) minutes. Check for leaks at filter base and oil pan drain

plug during operation.

J. Shut down engine and wait five (5) minutes. Check engine oil level and adjust to

proper level if necessary.

6. Engine Valve Lash Adjustment

NOTE: Required every 500 hours (1000, 1500, etc.) on non-emergency.

NOTE

Confirm that #1 piston is on the compression stroke by turning both pushrods by hand to verify

that both valves are closed. The valves are closed when the push rods are loose and can be

turned easily.

Engine can be barred over by installing 8mm-1.25 bolts in the six empty holes around the

crankshaft pulley and using a pry bar to turn the crankshaft.

A. Remove all valve covers.

B. Rotate the crankshaft until the number 1 piston is on the compression stroke and the

timing pointer on the front cover is in-line with the “TDC” mark on the crankshaft

damper. Some engines may have a permanent groove mark on the flywheel for

“TDC”.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

Loading...

Loading...