Operation and Maintenance Manual for WP2.1C/WP3.9C Series Marine Diesel

9

fracture of the engine.

Section

Ⅲ

Engine

Assembly

and

Disassembly

3.1 Cylinder Head

The monolithic cylinder head is made of high strength cast iron. The fuel

injectors and valve train parts are mounted on the cylinder head.

The cylinder head assembly is composed mainly of cylinder head, fuel injectors,

valve mechanism, intake and exhaust manifolds, front cover plate, rear cover plate,

thermostat and water temperature sensor.

The inlet and exhaust valve guides are of the same design. The valve guide and

valve seat insert are press-fitted into the cylinder head. The valves are not

interchangeable because they and their seats have been lapped in pairs to form

continuous, regular and bright seating lines. No leakage is allowed in the seat line

of the valve. The normal valve seating line width is 1.0~1.4mm. If it gets too wide to

ensure tight sealing, reshape it by means of a special reamer. Each valve is marked

with a cylinder number, because they are not interchangeable in assembly. The

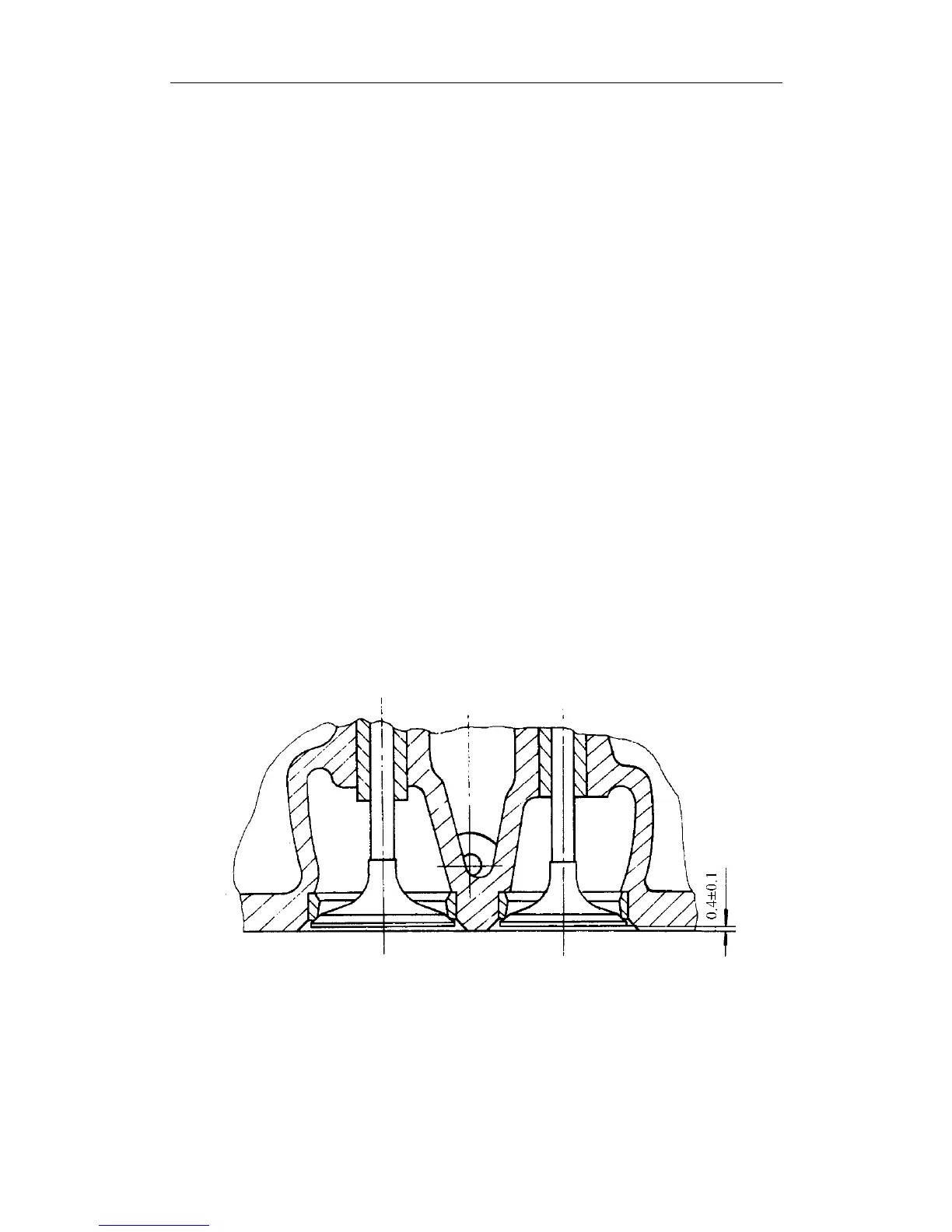

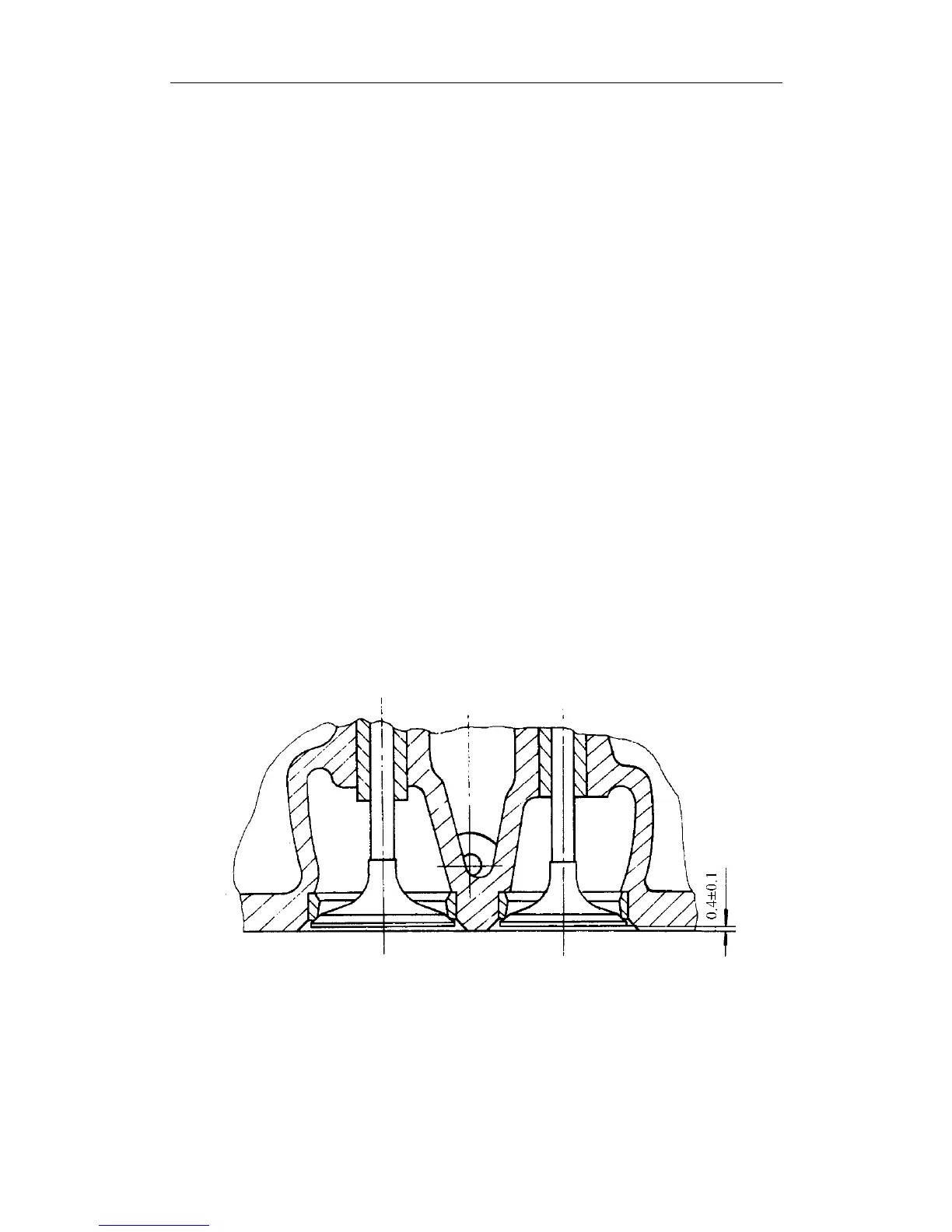

standard valve recession, i.e. the specified distance from the valve head to the cylinder

head surface is 0.4±0.1mm (see Fig.1). If the valve recession is too small, ream the

valve insert to enlarge it; if it is too large, replace the valve and valve seat.

Fig.1

The cylinder head is mounted on the cylinder block with 18 bolts. They should

be evenly tightened in 2~3 steps . The tightening of the bolts in each step should

Loading...

Loading...