Operation and Maintenance Manual for WP2.1C/WP3.9C Series Marine Diesel

13

The difference in weight between the piston-connecting assemblies for the same

engine should be less than 10 grammes. This requirement can be met through

selection.

The crankshaft is made of ductile nodular cast iron. There are five main journals

and four crankpins on the crankshaft. An oil hole in each journal leading to the

neighboring crankpin is employed to supply lubricating oil to the crankpin bearing.

On the front end of the crankshaft, there are the timing gear and oil pump driving gear,

both driven with a flat key. On the front and rear of the crankshaft, there are oil seals

to prevent oil leakage. When installing the flywheel, tighten the flywheel bolts evenly

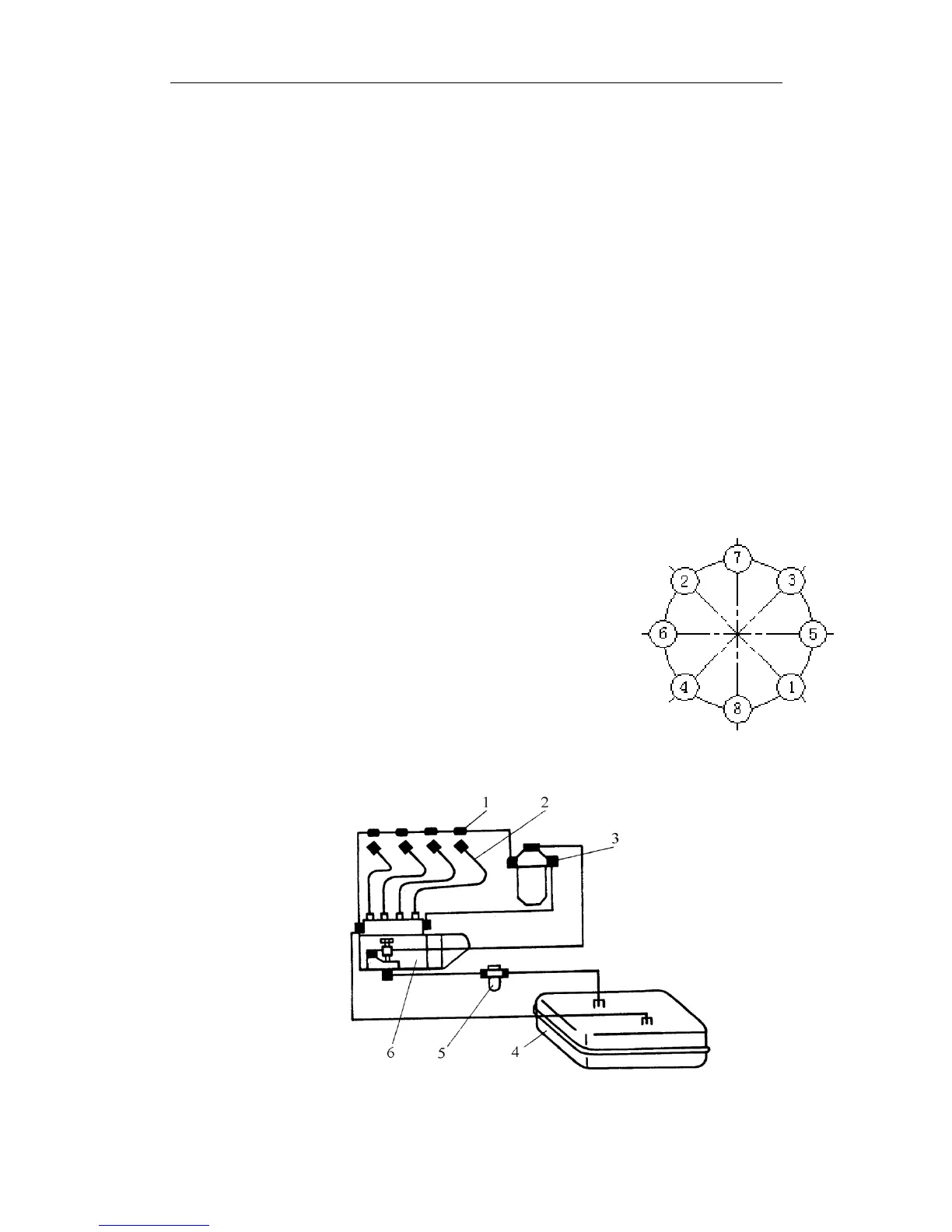

in the order shown in Fig.6 to reach the specified torque in 2~3 steps. The crankshaft

and flywheel are dynamically balanced as an assembly. The same figure is marked

side by side on the crankshaft flange end and the flywheel as an indication of the

pairing relation and mounting position. Be sure to assemble the flywheel with the

crankshaft in the correct position as indicated with the figure mark.

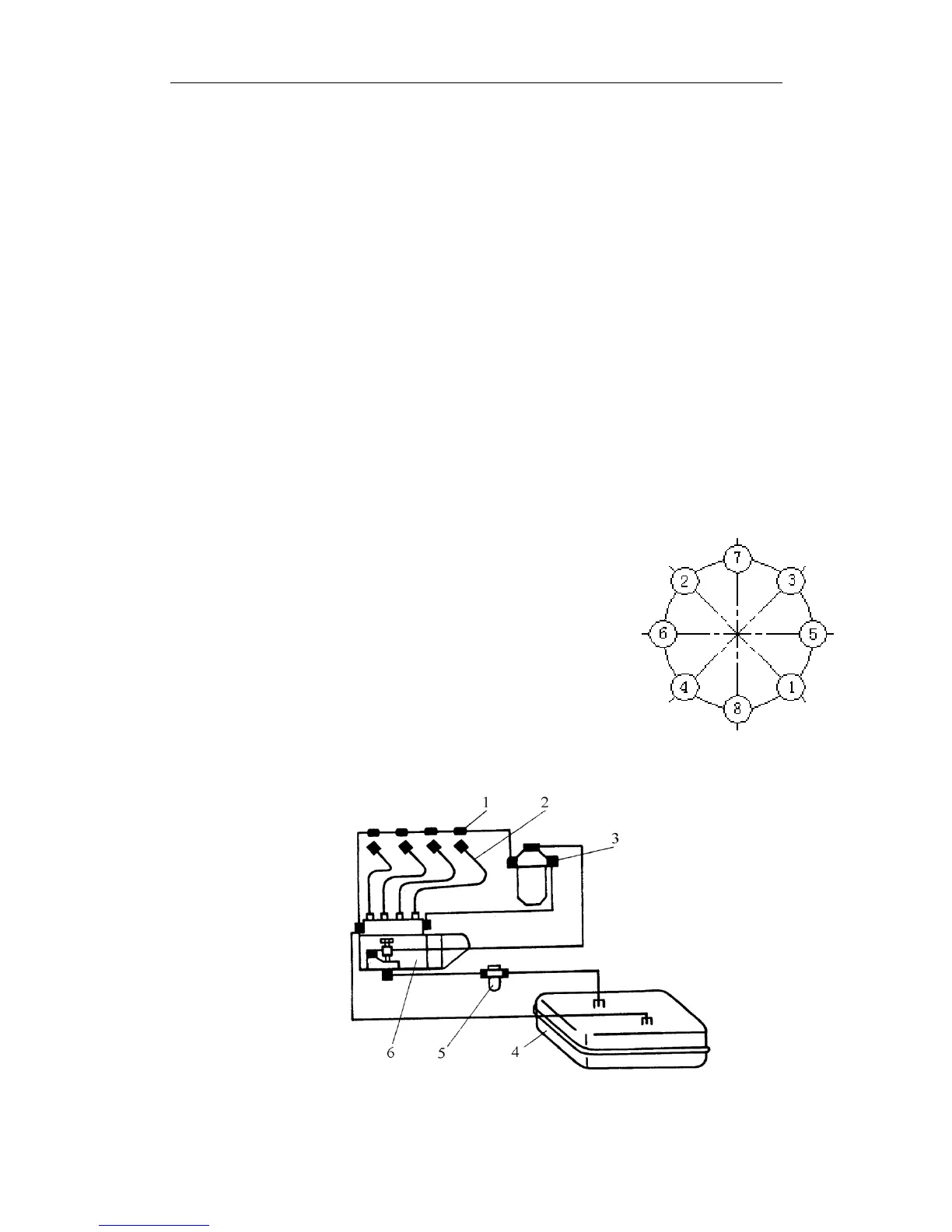

3.5 Fuel Supply System

The fuel supply system consists of the fuel tank, rough

filter, feed pump, fine filter, injection pump, governor, injectors

and fuel pipelines.Fuel from the fuel tank flows through the

strainer into the feed pump and then pass through the fuel filter

to the injection pump. The fuel at high pressure from the

injection pump is delivered to the fuel injector and sprayed into

the combustion chamber. The superfluous fuel from the

injection pump and injectors flows back to the fuel tank.(see

Fig.7)。 Fig. 6

1. Fuel return pipe 2. Fuel injection pipe 3. Fuel fine

4. Fuel tank 5. fuel rough filter 6. Filter

Fig. 7

Loading...

Loading...