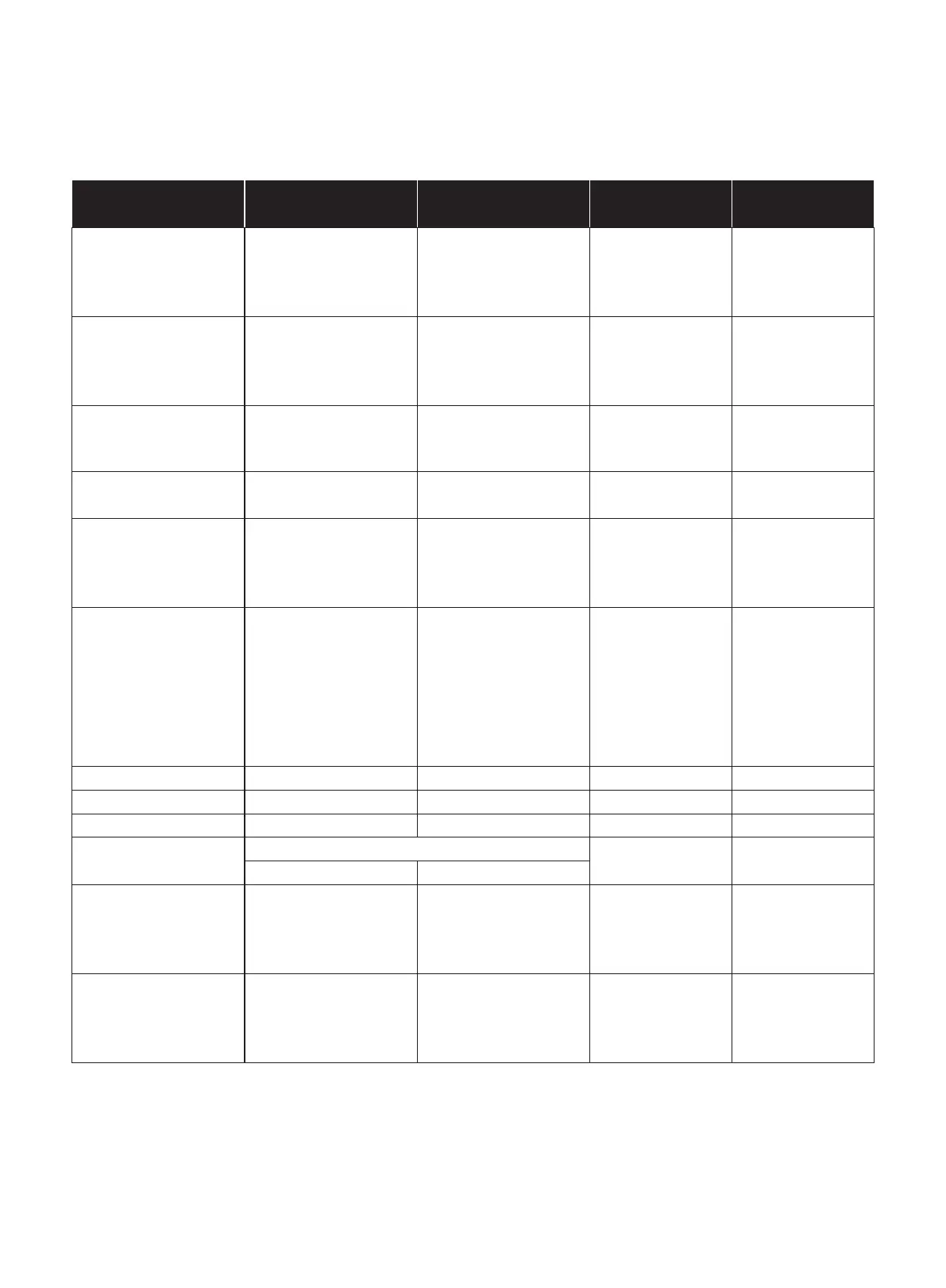

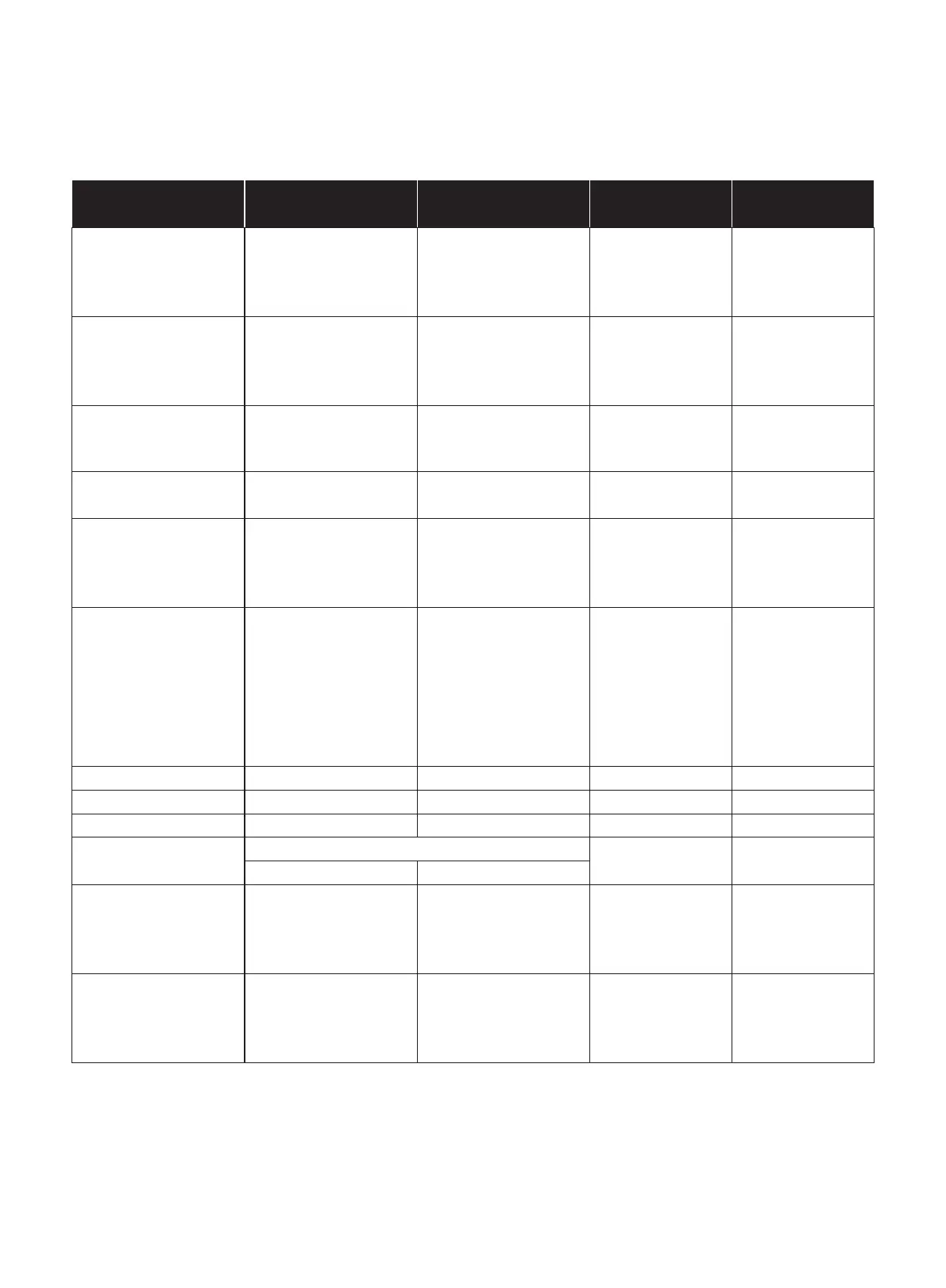

8. Lens Shade Selector Guide

Operation/Process

Electrode Size in. (mm) Arc Current (Amperes)

Minimum Protective

Shade

Suggested* Shade

No. (Comfort)

Shielded metal arc

welding (SMAW)

Less than 3/32 (2.5)

3/32−5/32 (2.5−4)

5/32−1/4 (4−6.4)

More than 1/4 (6.4)

Less than 60

60−160

160−250

250−550

7

8

10

11

—

10

12

14

Gas metal arc welding

(GMAW) and flux cored

arc welding (FCAW)

Less than 60

60−160

160−250

250−550

7

10

10

10

—

11

12

14

Gas tungsten arc welding

(GTAW)

Less than 50

50−150

150−500

8

8

10

10

12

14

Air carbon arc cutting

(CAC−A)

Less than 500

500−1000

10

11

12

14

(Light)

(Heavy)

Plasma arc welding

(PAW)

Less than 20

20−100

100−400

400−800

6

8

10

11

6 to 8

10

12

14

Plasma arc cutting (PAC)

Less than 20

20−40

40−60

60−80

80−300

300−400

400−800

4

5

6

8

8

9

10

4

5

6

8

9

12

14

Torch brazing (TB)

3 or 4

— —

Torch soldering (TS)

2

— —

Carbon arc welding (CAW)

14

— —

Plate thickness

Mmin.

Oxyfuel gas welding (OFW)

Light

Medium

Heavy

Under 1/8

1/8 to 1/2

Over 1/2

Under 3.2

3.2 to 12.7

Over 12.7

4 or 5

5 or 6

6 or 8

Oxygen Cutting (OC)

Light

Medium

Heavy

Under 1

1 to 6

Over 6

Under 25

25 to 150

Over 150

3 or 4

4 or 5

5 or 6

As a rule of thumb, start with a shade that is too dark to see the weld or cut zone. Then go to a lighter shade which gives

sufficient view of the weld or cut zone without going below the minimum. In oxyfuel gas welding, cutting, or brazing where the

torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line in the visible light of

the (spectrum) operation.

Guide adapted from ANSI Z49.1, 2012.

16

Loading...

Loading...