4

English

ENG

are damaged

►

Many accidents are caused by

poorly maintained airless tools

►

Use airless tools,

accessories and tool tips, etc. according to these

instructions and in the manner provided for the

particular type of airless tool, taking into account

the conditions work and work to develop

►

The use

of the airless tool for applications other than those

intended could result in a dangerous situation

►

Please check your airless tool serviced by a

Werku

®

ocial repair service using only identical

replacement parts

►

This will ensure the safety of

the airless tool is maintained.

CHECK THE GOOD CONDITION OF THE

AIRLESS GUN.

►

Make sure that all the screws in the airless

gun are perfectly tightened

►

Make sure that the

possible installed accessories are perfectly tted in

place.

BEFORE STARTING WORK.

►

Make sure that the suction airless gun is rmly

supported before using

►

Check that no one is

standing beneath you when using the suction

airless gun in high areas.

DURING THE OPERATION.

►

Do not leave the suction airless gun operating

without having it rmly xed

►

Only turn it on when

you are sure you have full control over it

►

Do not

point the suction airless gun at anyone while in

use

►

When operating the suction airless gun will

produce vibrations

►

The screws may gradually

come loose, and possibly cause faults or accidents.

AT FINISH WORKING.

►

Do not touch the possible accessories installed

in the suction airless gun after use

►

It may be

hot and cause burns

►

Some materials worked

with may contain chemicals or toxic components

►

Avoid inhaling these substances or allowing

them to come into contact with your skin

►

Use

PPE designed to prevent and protect against

incidents of this kind.

DESCRIPTION OF THE PRODUCT.

►

The airless gun has been designed for the high

pressure atomization of liquid coating materials

►

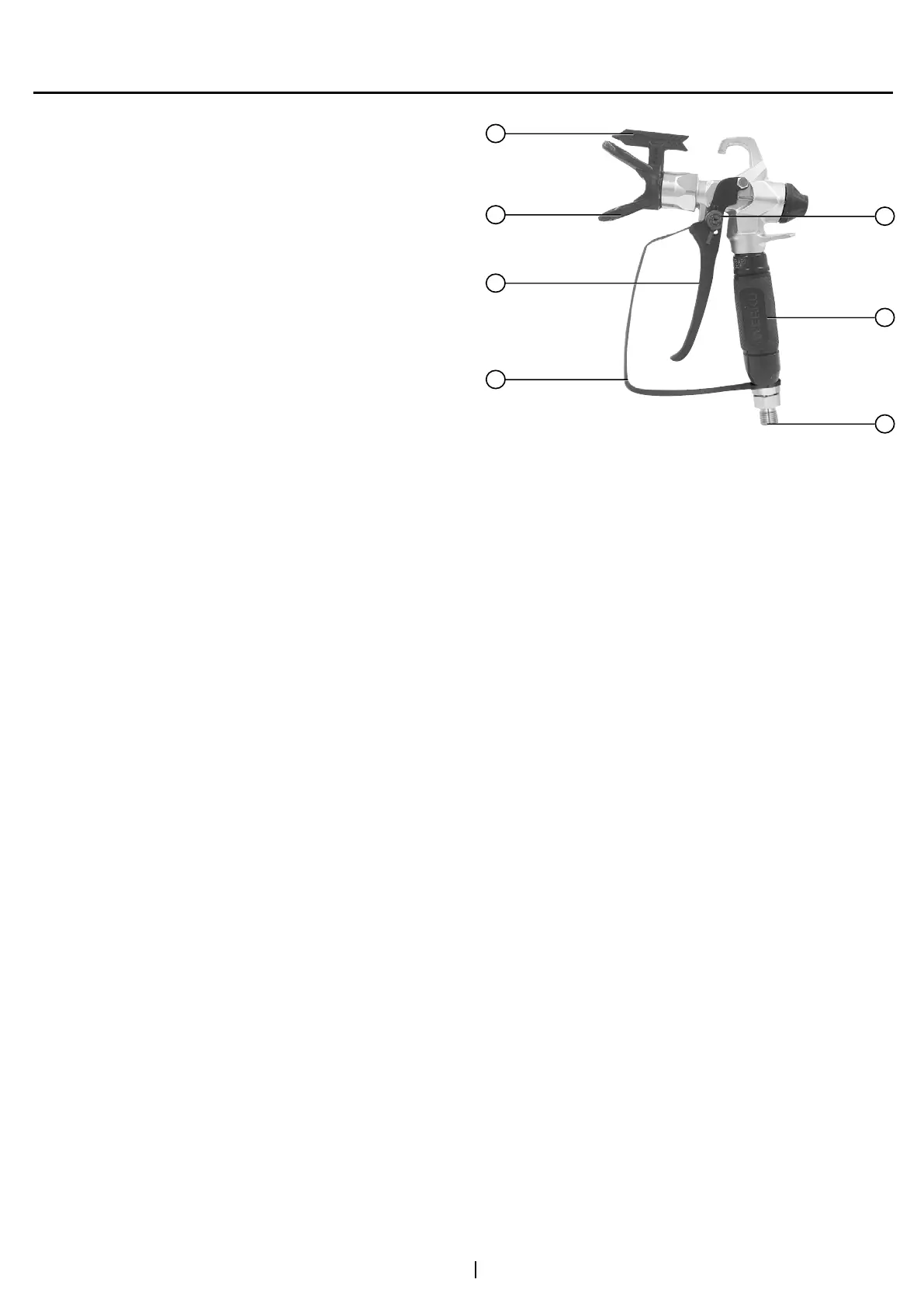

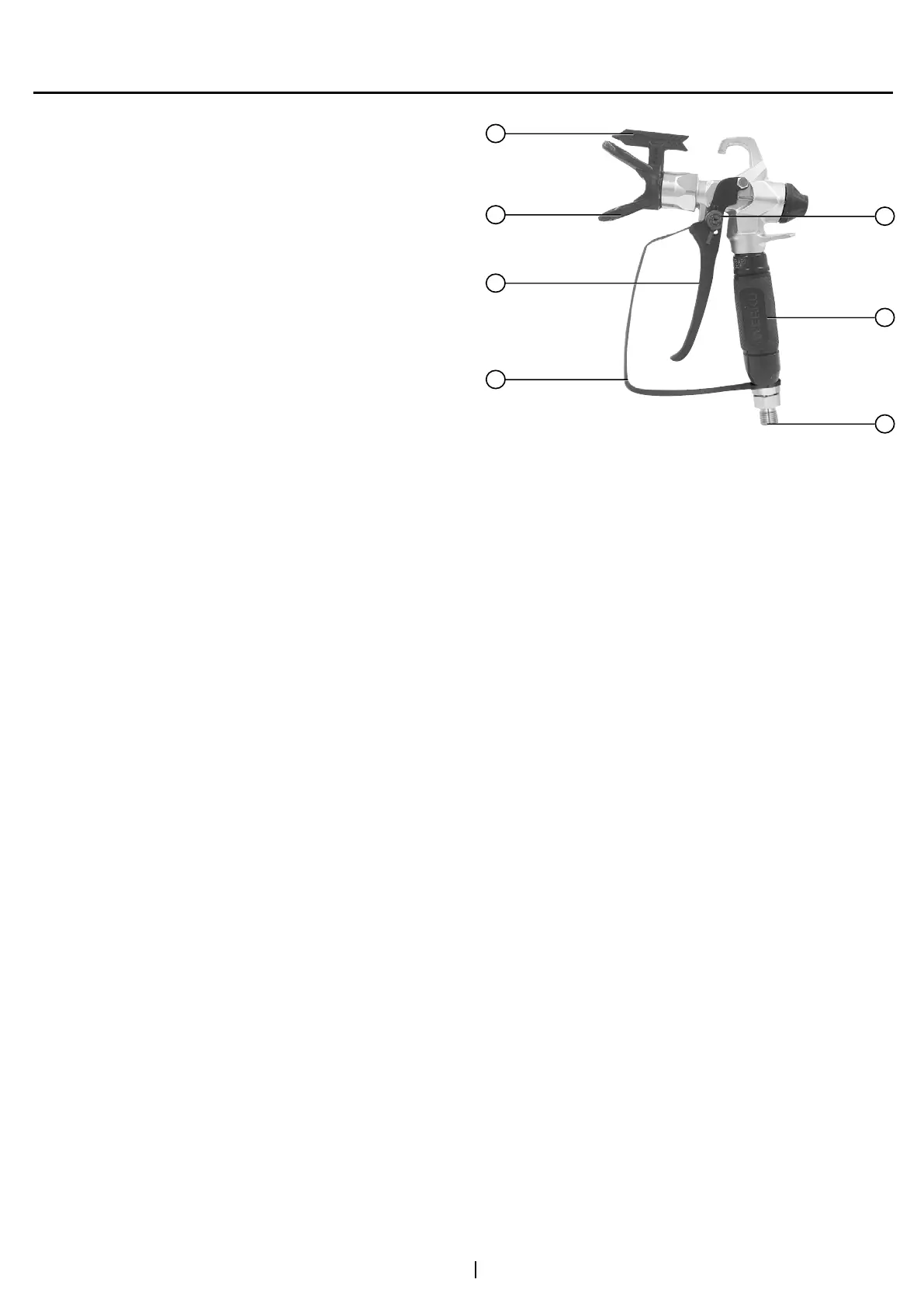

Refer this plan to familiarize yourself with the

airless gun before use.

2

5

6

7

4

1

3

1. Tip.

2. Tip guard.

3. Trigger.

4. Trigger guard.

5. Trigger lock.

6. Handle.

7. Material inlet.

USE INSTRUCTIONS .

►

Before putting the airless gun into operation, it

is advisable to read all the indicated instructions

►

Likewise, accident prevention rules, regulations

and guidelines for work centres and current laws and

restrictions must be taken into account

►

The airless

gun must be used only by personnel who have been

trained adequately in their handling, and only for the

uses for which it has been designed.

USING TRIGGER LOCK.

►

Always engage the trigger lock when the airless

gun is not in use (1)

►

To lock the trigger, rotate

the trigger lock until it stops (2)

►

To unlock the

trigger, rotate the trigger lock back (3).

SETUP.

►

Never attempt to assemble, change, or clean

the airless gun, tip or tip guard without rst

relieving pressure from the spray system

►

Follow

the pressure relief procedure in the sprayer’s

owner’s manual

►

Always use a tip safety guard

for added protection against injection

►

Beware

that the guard alone will not prevent injection

►

Never cut o tip guard

►

Always engage

trigger lock when the airless gun is not in use

►

Before servicing equipment, consult owner’s

Loading...

Loading...