9

EN

OPERATING INSTRUCTIONS

NOTE: Before using the tool, read the instruction

book carefully.

INTENDED USE:

The machine is intended for sawing wood, plastic,

metal and building materials while resting firmly on the

workpiece. It is suitable for straight and curved cuts with

bevel angles to 45°. The saw blade recommendations are

to be observed.

1.ON/OFF SWITCH

Depress to start and release to stop your tool. (See Fig. A)

2. SWITCH LOCK-ON BUTTON

Depress on/off switch (2) then lock-on button (3) (See

Fig. B), release on/off switch first then lock-on button

second. Your switch is now locked on for continuous

use. To switch off your tool just depress and release on/

off switch.

3. VARIABLE SPEED CONTROL

Adjust the thumb-wheel to increase or decrease the

speed (See Fig. C) according to the material, material

thickness and blade specification to be used (also

possible during no load operation). See Chart 1 for

general guidance on speed selection.

Avoid prolonged use at very low speed as this may

damage your jigsaw’s motor.

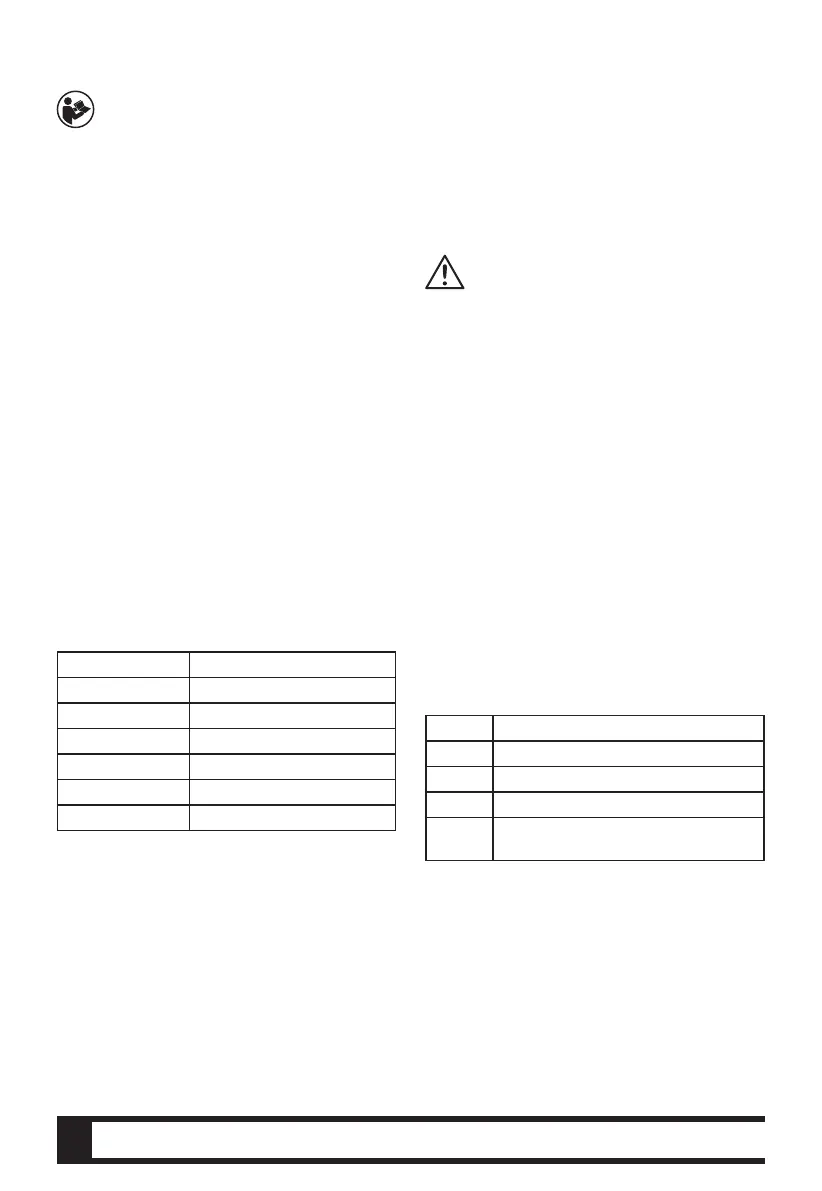

Chart 1

Material Speed setting

Wood 5-6

Metal 3-4

Aluminum 3-5

PVC 3-4

Ceramic 3-5

4. HAND GRIP AREAS

Always ensure you maintain a firm grip whilst operating

your jigsaw.

5. ALLEN KEY STORAGE

The allen key (5) is placed at the power cable sheath (See

Fig. D).

6. BLADE FITTING (See Fig. E)

NOTE: Remove the plug from the socket before

carrying out any adjustment, servicing or

maintenance.

To fit blade firstly use the allen key provided to loosen

the blade set screws on the blade holder. The blade’s

cutting edge should be facing forward. Insert the blade’s

mounting portion into the groove in the blade holder until

it touches the bottom of the holder. Then firmly tighten

the set screw as shown in Fig. E.

NOTE: To fit the blade firmly, do not insert the blade over

the line. (See Fig. G)

WARNING: Blade teeth are very sharp. For best

cutting results ensure you use a blade suited to

the material and cut quality you need.

7. ROLLER GUIDE (See Fig. F)

Ensure the blade is located and runs smoothly in the

groove (See Fig. F) otherwise the pendulum function will

not work correctly and the blade will not be supported

during cutting.

8. MOUNTING PARALLEL GUIDE (See Fig. H1, H2)

Slide the parallel guide arm through both parallel guide

fixtures and tighten the locking knob (a) to achieve the

required cutting distance. The parallel guide can be

mounted in two positions as shown in H1 and H2.

9. PENDULUM ACTION CONTROL (See Fig. I)

The pendulum action varies the forward cutting angle of

the blade for increased cutting efficiency. This can also

be adjusted during no load running. Refer to the chart 2

for more details. Do not use excessive blade force when

cutting with the pendulum action. The blade cuts on the

upward stroke only.

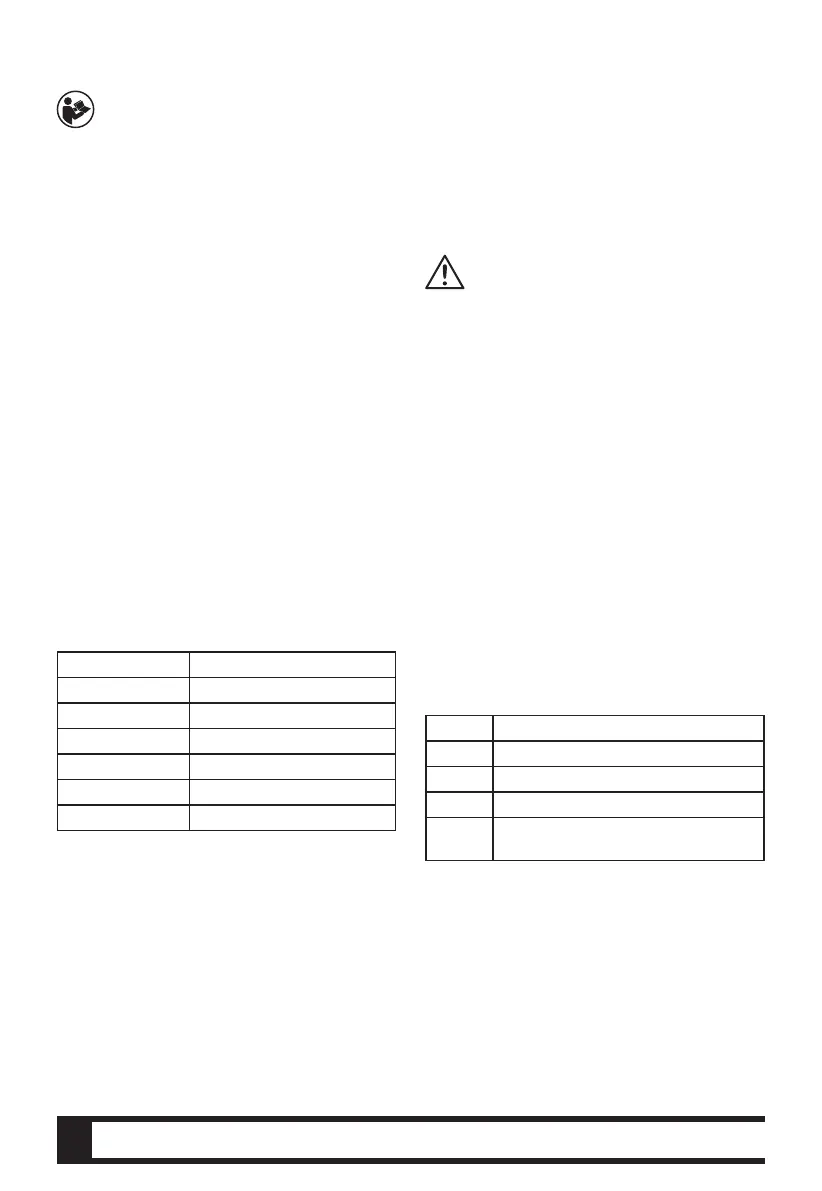

Chart 2

0 Thin materials. Fine cuts. Tight curves.

I Hard materials, (e.g. steel & chipboard)

II Thick materials ( e.g. wood ) & plastic

III

Fast cuts (e.g. softwood). Cutting in the

direction of the wood grain.

10. BASE PLATE

Adjusting the angle of the base plate (7) enables bevel

cutting. The base plate must always be held firmly

against the materials being cut to reduce saw vibration,

blade jumping or blade breakage.

11. BASE PLATE ANGLE ADJUSTMENT

Use an Allen key (5). Loosen the bolts securing the

base plate (See Fig. J). For preset angles, rotate so the

lines of the angle on the base plate and angle plate

Loading...

Loading...