5

5. Please guarantee there is oil (white oil) in the lubricator of second air

cylinder, but the oil level does not have to surpass 2/3, turn on the water

filter to clean according to the situation.

6. Fill oil in the guide pillar 1 – 2 times each operation, clean once a season

for the air operated parts.

7. Cut off the power once it has fault, and should be repaired by the specialist.

8. Power must connect the ground safely.

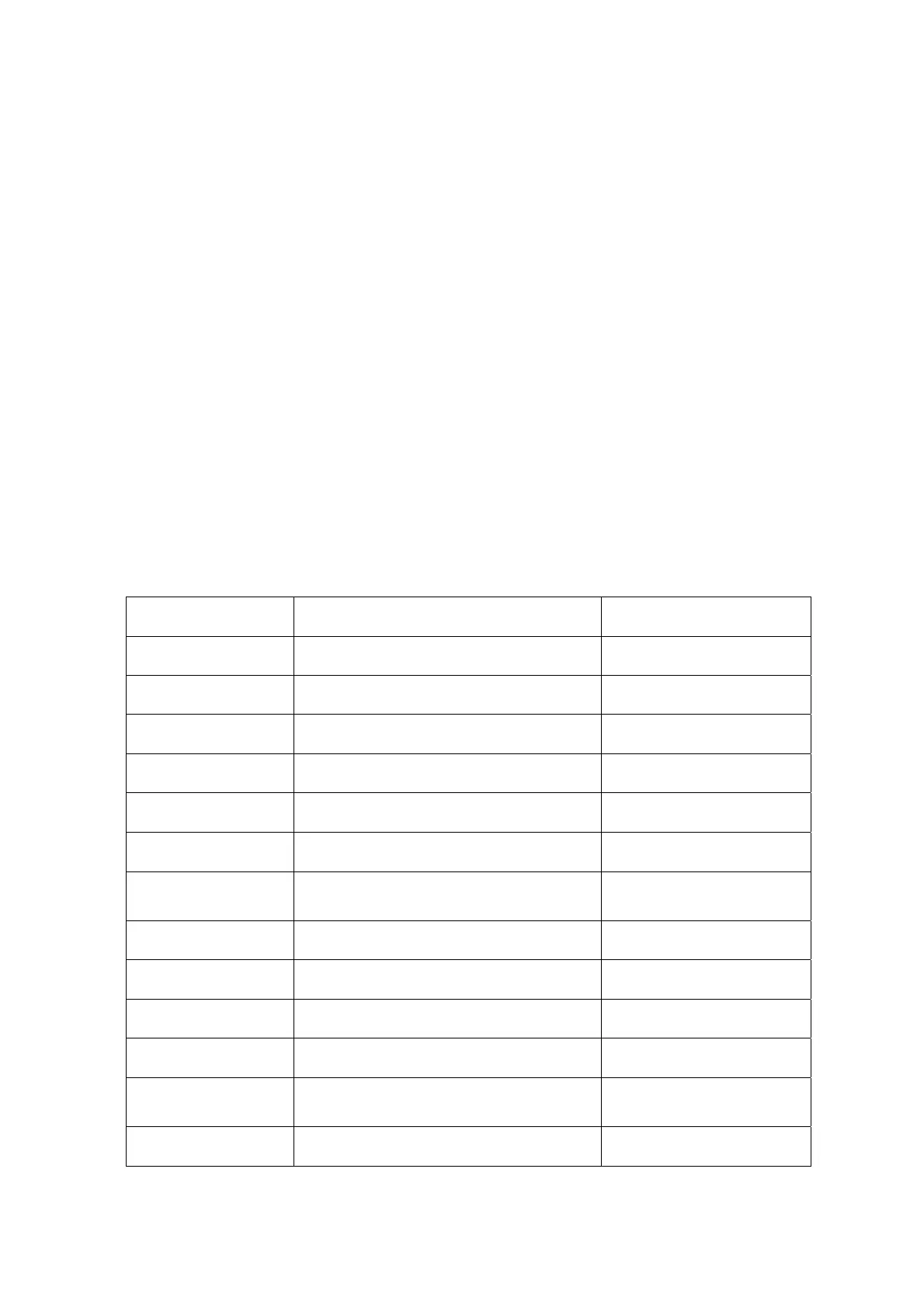

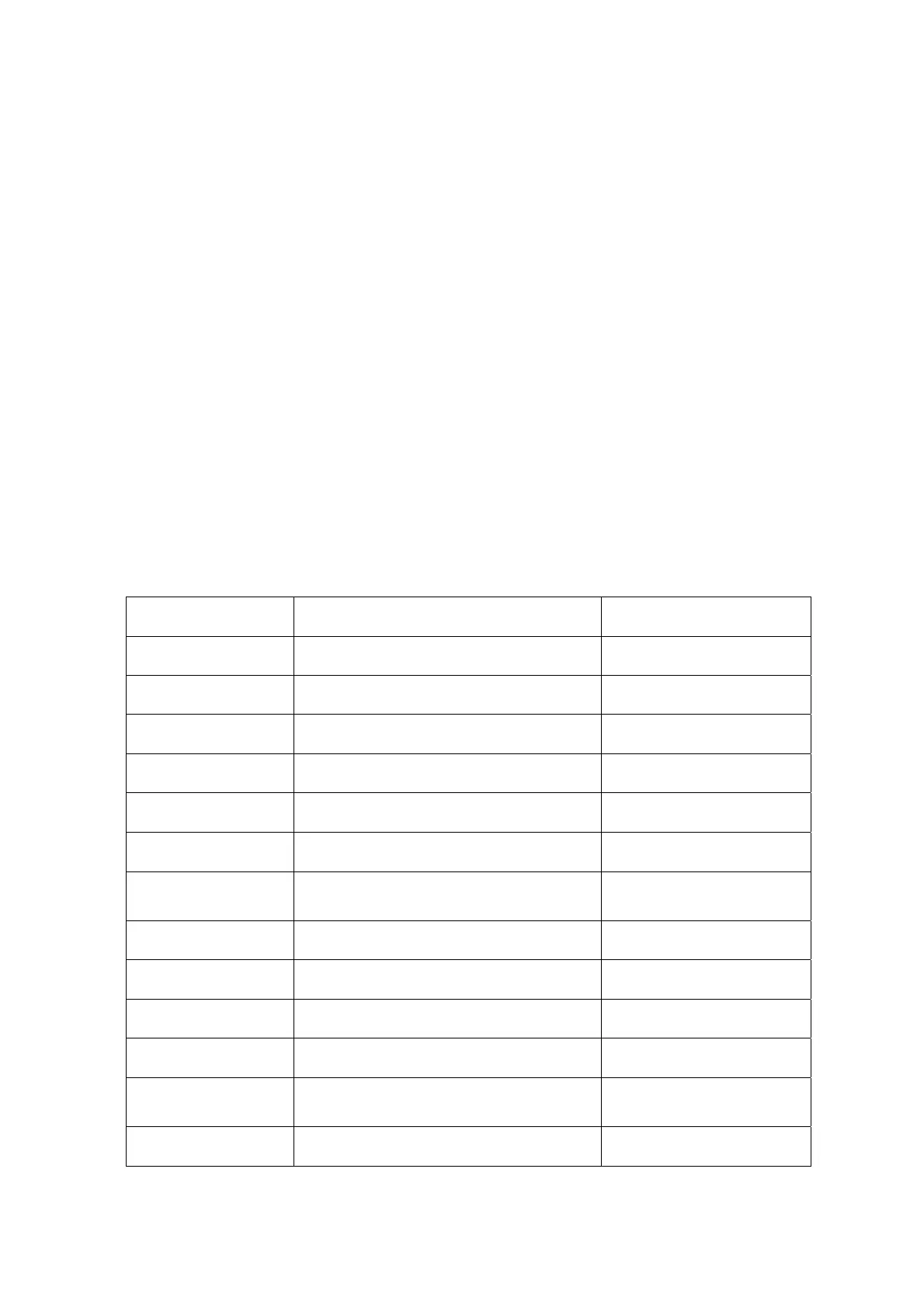

VIII. FAULTS AND PRECESSING MOTHOD

Phenomenon Reason Processing method

Burning Current conversion gear too high Adjust lower

Burning Heating time too long Adjust shorter

Cannot seal up Current conversion gear too low Adjust higher

Cannot seal up Heating time too short Adjust longer

Cannot seal up Card paper have no glue Stick glue on

Cannot seal up The plastic material is not good Change it

Mold hasn’t heat Connection of the electrode under the

turntable is not good

Change it

Mold hasn’t heat Fuse burns out Change it

Mold hasn’t heat AC contactor has malfunction Change it

Mold hasn’t heat The mold wiring is not solid Fix it

Mold hasn’t heat The transformer burns out Change it

Product takes out

difficultly

Cooling time too short Delay longer

Partial wrinkle Delayed time too shorter Delay longer

Loading...

Loading...