29 - Installation requirements -

Shut off valves in the suction line shall be sized generously and without reducers to enable

degassing. Installation of full-bore ball valves are recommended. Straight through valves must

be installed with stem in horizontal position; ball valves should not have a reduced bore on the

pump side connection.

Until now we have not recommend filters in the liquid downleg as these create additional pres-

sure loss. How-ever, positive experience has proven that the use of filters in systems with high

levels of contamination (i.e. due to installation of non-shot blasted pipes and vessels) is better

than contamination of the pump.

Filters with a mesh of 500 µm (e.g. Parker T5F-SS, AWP-SS, RFF FA or Danfoss FIA) should

be installed in systems with a potential for contamination.

Upmost care should be taken to clean the filters as often as possible during

the first weeks of operation, until they remain clean.

Since external filters have a larger filter surface and can be cleaned more easily, we recom-

mend you keep these in place and remove the conical filter in the pump inlet to avoid two filters

causing excessive pressure drop. A regu-lar check (1 – 2 per year) should be included in the

maintenance routine.

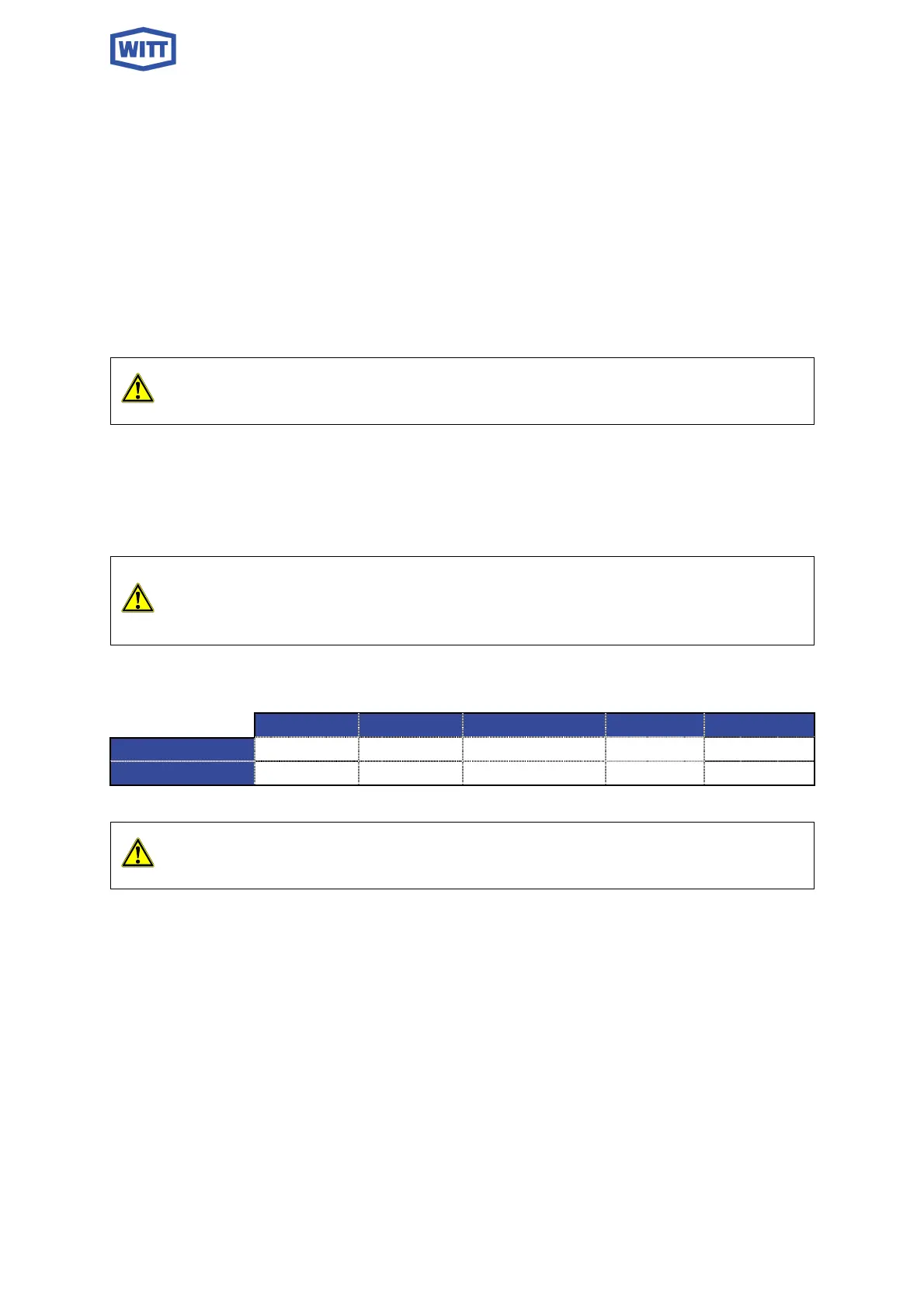

To be sure the pump will operate even at a low-pressure difference resulting

in maximum capacity, the diameter of the downleg to the pump must be

executed as mentioned in the table below as a minimum!

Required diameter of the downleg to the pumps

GP 41 GP 42 GP 51 / GP 51a GP 52 GP 82

50 Hz DN 80 DN 80 DN 100 DN 150 DN 150

60 Hz 3” 3” 4“ 6“ 6“

Under no circumstances should the maximum velocity in the downleg exceed 0.3

m/s (1 ft/s)!

The conical suction filter supplied with the pump must be installed at all times to protect the

pump from foreign material contamination!

Loading...

Loading...