This document is a comprehensive manual for the Woods Mow'n Machine, a line of commercial-grade zero-turn mowers designed for efficient and precise lawn care. The manual covers various models, including the CZ2048K, CZ2252K, CZ2361B, and CZ2461K, with different engine configurations (Kawasaki and Briggs & Stratton) and deck sizes (48", 52", and 61" side discharge).

Function Description

The Woods Mow'n Machine is a zero-turn mower primarily designed for cutting grass. Its zero-turn capability allows for highly maneuverable operation, enabling tight turns and efficient navigation around obstacles, which is particularly beneficial for complex landscapes and large areas. The side discharge feature ensures that cut grass is expelled to the side, preventing clumping and allowing for a clean cut. The machine is built for professional use, emphasizing durability and performance.

Important Technical Specifications

The manual details several engine and deck configurations:

- CZ2048K: 20HP Kawasaki engine with a 48" side discharge deck.

- CZ2252K: 22HP Kawasaki engine with a 52" side discharge deck.

- CZ2361B: 23HP Briggs & Stratton engine with a 61" side discharge deck.

- CZ2461K: 24HP Kawasaki engine with a 61" side discharge deck.

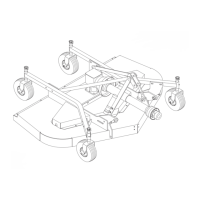

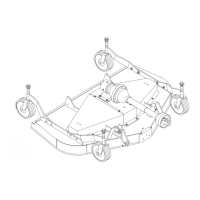

All models feature a robust frame-engine/clutch assembly, a transaxle assembly for power transmission, and a fuel tank/bumper & control panel for operational control and protection. The deck lift assembly allows for easy adjustment of cutting height. Caster wheels provide stability and maneuverability.

Usage Features

The manual provides detailed instructions for safe operation, including:

- Set-Up Instructions: Covers uncrating, tire pressure adjustment (14 lbs/in² or 1.0 kg/cm² for shipping, then adjusted for operation), and traction lever setup.

- Final Preparations: Emphasizes checking engine and hydraulic oil levels, battery connections, and ensuring the operator's manual is located under the seat.

- Controls: Explains the functionality of the key switch (OFF, RUN, START), throttle (T), choke (C), power take-off (PTO) switch (P), hour meter (M), 12-volt power outlet (X), fuel selector valve (U), lift and traction levers (L, S, F, A), and parking brake (R).

- Pre-Operation Checklist: A comprehensive list of checks to perform before each use, including safety decals, shields, guards, hardware, power unit, cooling fins, hydrostatic fluid, and interlock system.

- Operation: Detailed steps for fueling, starting the engine, operating notes, driving instructions (forward and reverse movement, turning), and cutting tips for optimal performance.

- Maneuvering Slopes: Specific warnings and guidelines for operating on slopes to prevent accidents, emphasizing slow movement, avoiding sudden changes in speed or direction, and maintaining stability.

Maintenance Features

The manual outlines a thorough maintenance schedule to ensure the longevity and optimal performance of the Mow'n Machine:

- Maintenance Chart: Provides a schedule for maintenance operations based on hours of use (First 5 hours, Every 25 hours, Every 50 hours, Every 100 hours, Every 200 hours, Yearly).

- Engine: Check/top up oil level, check for leaks, clean air intake screen, clean air cleaner pre-cleaner and element, change oil and filter, check/replace spark plugs.

- Transaxle: Check oil level, check for leaks, change oil and filter.

- Machine: Check interlock operation, check tire pressures, check/top up battery, lubricate all points.

- Maintenance Record: A dedicated section to log maintenance activities, including dates and hours.

- Check Daily: Instructions for daily checks of the operator presence interlock system, hardware, tire pressure, and battery.

- Lubrication: Specifies lubrication points and frequency (every 50 hours for deck lift lever and pivots, every 500 hours or once a year for caster wheel pivots).

- Engine Oil: Instructions for checking and changing engine oil, including the first oil change after 5 hours of operation.

- Spark Plugs: Guidelines for checking and replacing spark plugs.

- Fuel Filter: Instructions for inspecting and replacing the fuel filter.

- Air Cleaner: Steps for cleaning and replacing air cleaner elements.

- Cleaning Machine: Recommendations for cleaning the machine after use, including brushing off clippings and debris.

- Washing Machine: Cautions against using high-pressure washers directly on bearings and other components.

- Engine Cooling: Daily and every 100 hours checks for the air intake screen and cooling fins.

- Specific Torques: A table listing torque specifications for various components like blade bolts, wheel hub nuts, engine crankshaft bolt, transaxle pulley nut, transaxle drain plug, and transaxle filter.

- Purging Transaxles: Instructions for purging the hydrostatic drive system to ensure proper function.

- Transaxles: Detailed steps for transaxle fluid change and purging, including warnings about overfilling.

- Blade Removal and Balance: Instructions for safely removing, sharpening, balancing, and installing blades.

- Deck Leveling: Steps for parking the machine, lowering the deck, measuring cutting height, and adjusting nuts for proper deck leveling.

- Height of Cut: Instructions for adjusting the height of cut using the height of cut pin.

- Deck Rollers: Information on adjusting deck rollers for continuous ground contact.

- Parking Brake Adjustments: Detailed procedures for adjusting the parking brake for 36", 48", 52", and 61" models.

- Hydrostatic Transaxle Adjustments: Steps for adjusting the hydrostatic transaxle for neutral position.

- Arm Rest Height Adjustments: Instructions for adjusting the height of the armrests.

- Seat Adjustment: Steps for adjusting the seat plate.

- Belt Replacement: Procedures for replacing the cutterdeck belt and hydro transaxle drive belt, including tensioning instructions.

The manual also includes important safety information, Proposition 65 warnings, and warranty details, emphasizing the importance of reading and understanding the manual before operation or maintenance.

Loading...

Loading...