Owner Service 17

MAN0476 (Rev. 2/10/2006)

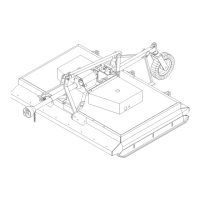

Sharpen Blades

IMPORTANT

■ When sharpening blades, grind the same

amount on each blade to maintain balance.

Replace blades in pairs. Unbalanced blades will

cause excessive vibration, which can damage

gearbox bearings. Vibration may also cause struc-

tural cracks to cutter.

Figure 6. Sharpen Blade

1. Sharpen both blades at the same time to maintain

balance. Follow original sharpening pattern.

2. Do not sharpen blade to a razor edge, leave at

least a 1/16" blunt edge.

3. Do not sharpen back side of blade.

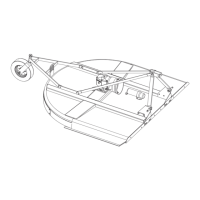

DRIVELINE SLIP CLUTCH ADJUSTMENT

The slip clutch is designed to slip so that the gearbox

and driveline are protected if the cutter strikes an

obstruction.

A new slip clutch or one that has been in storage over

the winter may seize. Before operating the cutter, make

sure it will slip by performing the following operation:

1. Turn off tractor engine and remove key.

2. Remove driveline from tractor PTO.

3. Loosen eight 10 mm cap screws (2) to remove all

tension from clutch pressure plate (3) and clutch

flange yoke (7). See Figure 7.

4. Hold clutch hub (5) solid and turn shaft to make

sure clutch slips.

5.

If clutch does not slip freely, disassemble and clean the

clutch flange yoke (7) and clutch pressure plate (3).

6. Reassemble clutch.

7. Tighten clutch springs (8) until springs are

compressed to 1.10". See Figure 7.

8. If a clutch continues to slip when the springs are

compressed to 1.10", check clutch discs (4) for

excessive wear. Discs are 1/8" when new. Replace

discs after 1/16" wear. Minimum disc thickness is

1/16".

Figure 7. Slip Clutch Assembly

1/16"

Follow Original Pattern

Maintain Corner

CD1257-2

1.10" REF

7

2

3

4

5

4

CD6824

8

2. M10 x 1.5 x 80 Hex head bolt

3. Clutch pressure plate

4. Clutch disk

5. Support hub

7. Clutch flange yoke

8. Clutch spring

Loading...

Loading...