26 Assembly

MAN0476 (Rev. 2/10/2006)

ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Assembly of this cutter is the responsibility of the

Woods dealer. It should be delivered to the owner com-

pletely assembled, lubricated, and adjusted for normal

cutting conditions.

The cutter is shipped partially assembled. Assembly will

be easier if aligned and loosely assembled before tight-

ening hardware. Recommended torque values for hard-

ware are located in the Bolt Torque Chart, page 39.

Complete Dealer Check Lists, page 30 when you have

completed the assembly.

Full chain, rubber, or steel band shielding,

designed to reduce the possibility of thrown

objects, must be installed when operating in popu-

lated areas or other areas where thrown objects

could injure people or damage property. If this

machine is not equipped with full chain, rubber, or

steel band shielding, operation must be stopped

when anyone comes within several hundred feet.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Operate tractor PTO at the rpm speed stated in

“Specifications” section.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

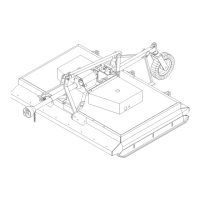

ASSEMBLE CUTTER

Disassemble Shipping Unit

1. Loosen mounting hitch pins.

2. Remove all parts that are wired and strapped to

cutter.

3. Remove tailwheel bracket, lift arms and height

adjustment bracket from cutter. Keep all hardware

for use in assembly.

4. Remove all hardware from manual tube.

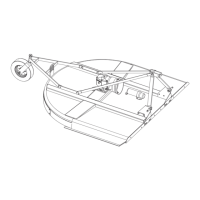

Install A-Frame to Lift Arms

1. Loosen mounting pin (7) and swing A-frame arms

to an upright position.

2. Loosen and remove M20 cap screw (5) and lock

nut (6).

3. Place lift arm (2) on the outside of A-frame arm (1),

slide M20 cap screw (5) through lift arm (2), A-

frame arm (1), sleeve (4), clevis (3), A-frame arm

(1) and lift arm (2). Secure with M20 lock nut (6)

and tighten.

4. Tighten mounting pin (7) Torque to 475 lbs-ft.

5. Tighten hardware at other end of lift arms.

Figure 21. Lift Arms to A-Frame Connection

CD6827

5

6

7

1

1

2

2

3

4

1. A-frame arm

2. Lift arm

3. Clevis

4. Sleeve

5. M20 x 1.5 x 140 Cap screw

6. M20 Lock nut

7. Mounting pin (Cat 1)

Loading...

Loading...