24 Operation

MAN0988 (11/5/2012)

Cultipacker

The optional cultipacker can be used to firm the seed

bed for small seeds and increase seed to soil contact.

The cultipacker is equipped to operate through an

inclusive angle of 37°. The cast iron cultipacker weight

provides the down pressure needed for an optimized

seedbed. When raising the seeder, the cultipacker will

swing until it reaches its lower stop. When raising the

seeder, use a slow and steady motion to reduce the

impact loading of the cultipacker on the frame stop. A

slot and 1/2" hardware are provided to secure the culti-

packer in a fixed position. To achieve a raised position,

move the cultipacker into a ditch or trailer ramp to

assist in lifting. Stop the engine of the power unit and

then tighten the cultipacker retainer to keep the culti-

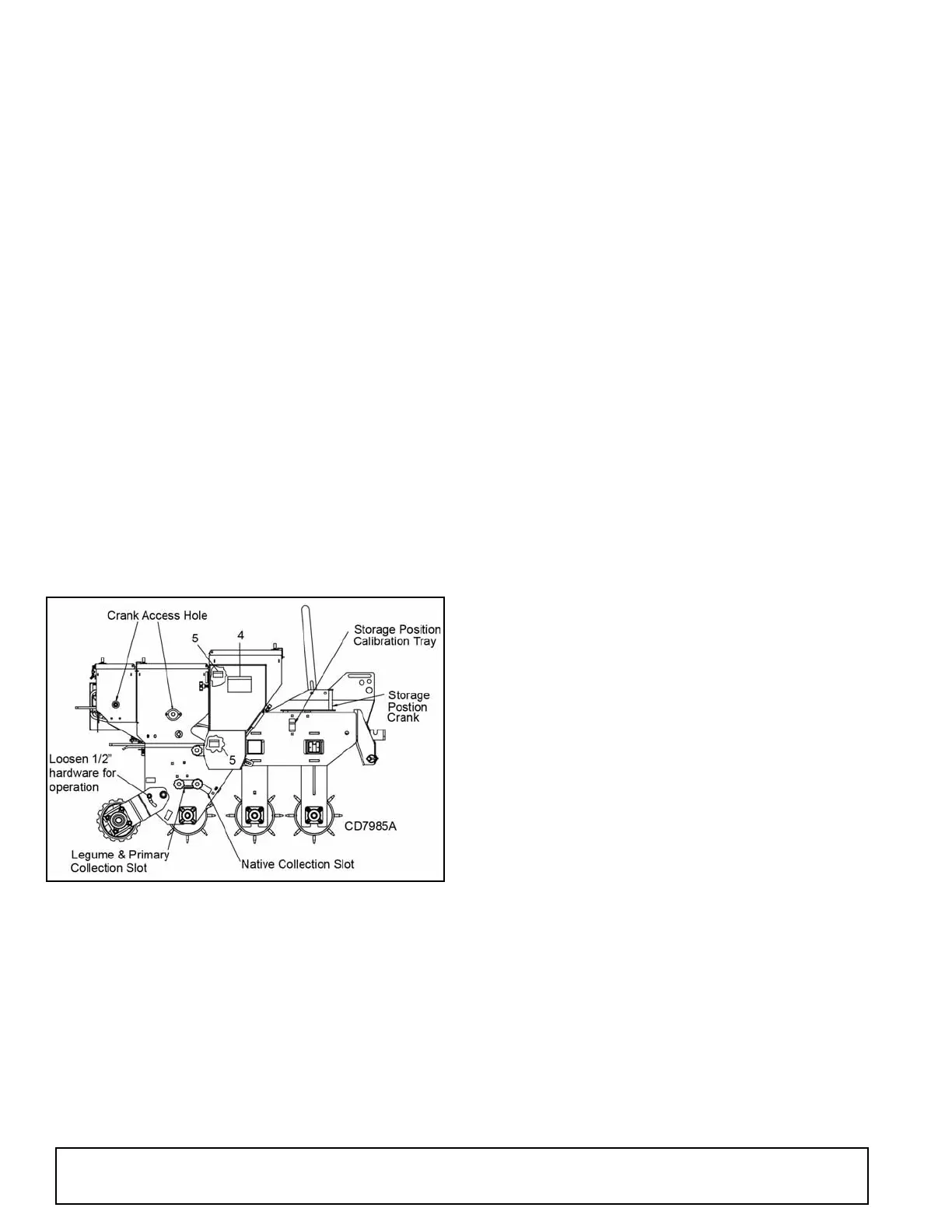

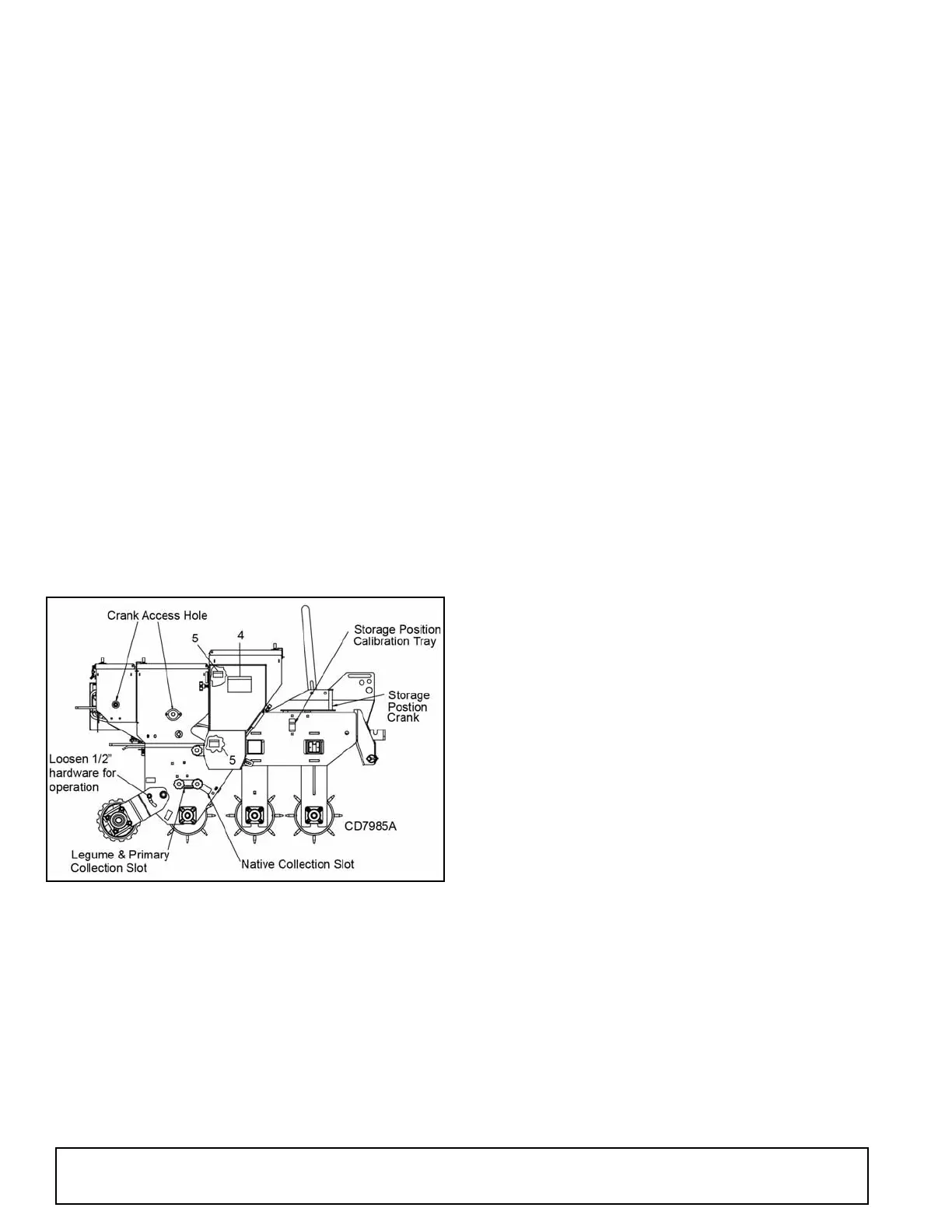

packer "raised". See Figure 31.

Calibration Tray

The Precision Super Seeder comes equipped with a

calibration tray to assist in adjusting the seed cups for

the desired seeding rate. The calibration tray can be

used with the seeder in the stationary position or as it is

pulled over a short distance of the seedbed. See Figure

31.

Figure 31. Calibration Tray

Stationary Calibration Procedure - Legume

and Primary Seed Boxes

Equipment

1. One or two pounds of sample seed.

2. Calibration tray.

3. One scale capable of measuring ounces or

hundreths of a pound.

Procedure

1. Position tractor and seeder on a level surface.

2. Adjust seed meter to closed position if applicable.

3. Stop engine and set parking brake.

4. Disconnect seed box from seeder chain drive by

removing pin from seed box driven sprocket

(Primary or Legume). For the native seed box,

leave chain drives connected between primary

seed cup shaft and picker wheels. Disconnect the

ground drive and legume seed box. Drive picker

wheels with primary seed cup shaft.

5. Place seed over two seed meters closest to right

end of seeder.

6. Remove calibration tray (34 cu. in. capacity) from

storage location. Install tray in designated

collection slot and tighten against frame with two

plastic nuts.

7. Open seed cups to desired position (refer to chart

for estimate) and lock into place. (Primary &

Legume Only)

8. Use crank or a 12-pt socket and turn primary seed

cup shaft clockwise or legume seed cup shaft

counter-clockwise. See stationary calibration chart

for number of shaft turns. (12-pt –3/4" or 19 mm

socket fits over Primary seed cup shaft. 12-pt 12

mm socket fits over Legume seed cup shaft)

9. Carefully remove calibration tray to retrieve

collected seed. Weigh seed and use formula to

determine seed rate. See page 20.

10. If seed rate is not correct, adjust seed cup

openings and repeat steps 7 through 9.

11. Return calibration tray and crank to storage

positions when finished.

Mobile Calibration Procedure - All Seed

Boxes

Equipment

1. One or two pounds of sample seed.

2. Calibration tray.

3. One scale capable of measuring ounces or

hundreths of a pound.

Procedure

1. Position tractor and seeder on a level surface.

2. Adjust seed meter to closed position if applicable.

3. Place seed over two seed meters closest to right

end of seeder.

4. Make sure the seed box being calibrated is

connected to chain drive. Disconnect other seed

boxes by removing pin from seed box driven

sprocket.

(Rev. 4/24/2018)

Loading...

Loading...