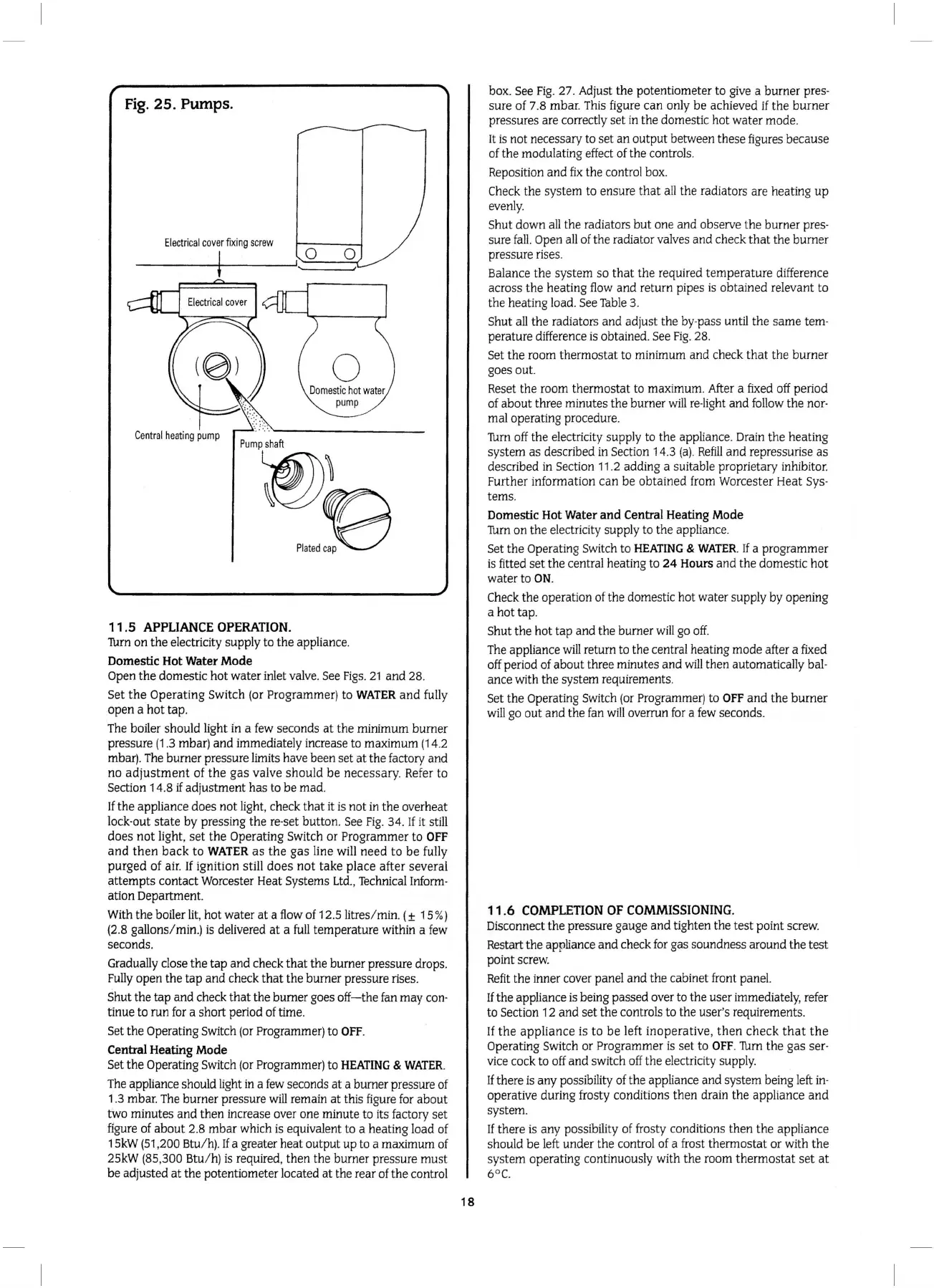

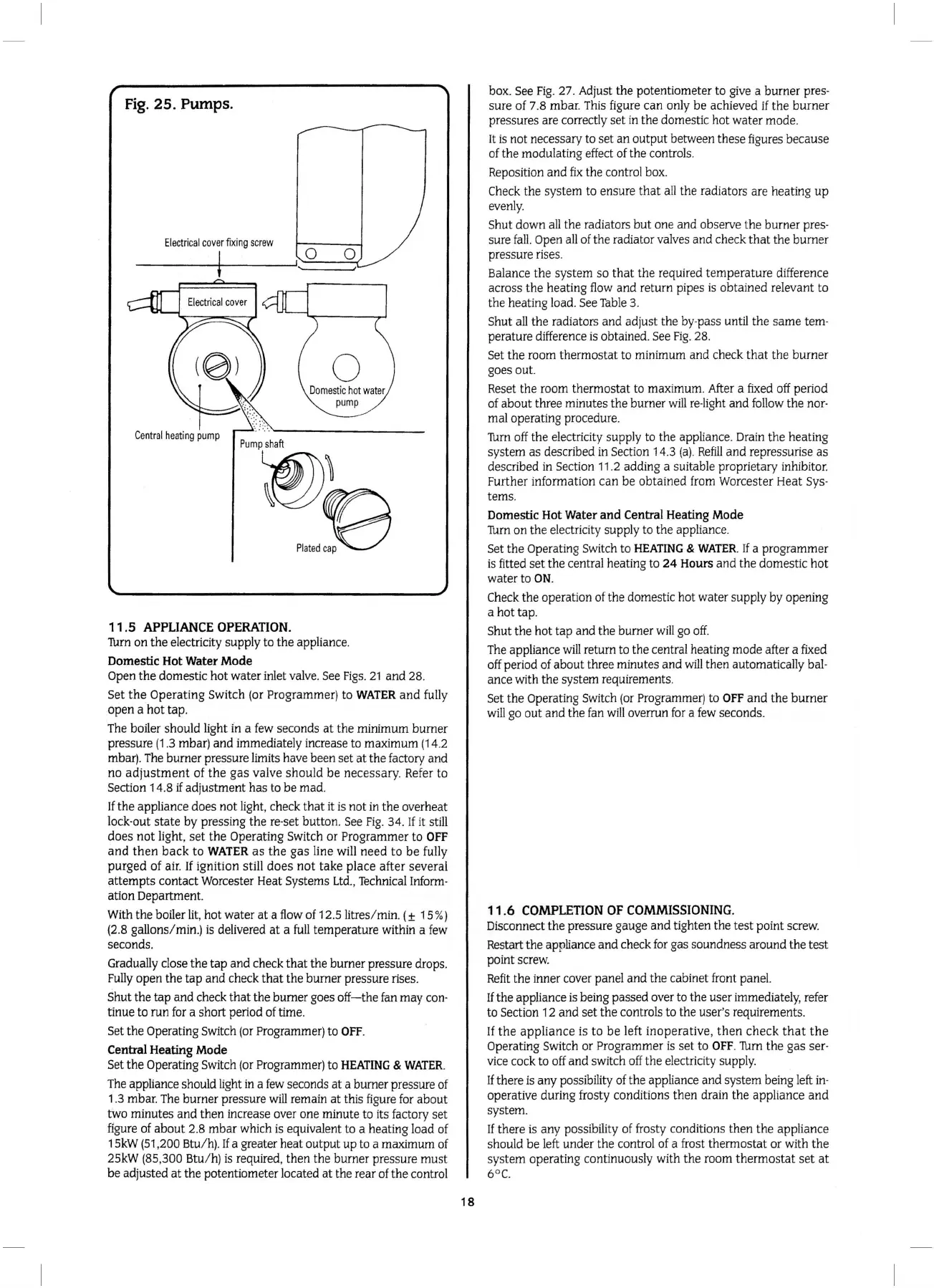

Fig.

25.

Pumps.

Electri

ca

l

cover

fixing

screw

0

0

Central

heat

ing

pump

11.5

APPLIANCE

OPERATION.

'fum

on

the

electricity supply to

the

appliance.

Domestic

Hot

Water

Mode

Open

the

domestic hot water inlet valve. See

Figs.

21

and

28.

Set

the

Operating Switch (or Programmer)

to

WATER

and

fully

open

a hot tap.

The boiler should light in a few seconds

at

the

minimum burner

pressure

(1

.3 mbar)

and

immediately increase to maximum (14.2

mbar).

The

burner pressure limits

ha

ve been set

at

the

factory

and

no

adjustment

of

the

gas

valve should

be

necessa

ry.

Refer to

Section 1 4.8

if

adjustment has to

be

mad

.

If

the

appliance does

not

light, check

that

it is not in

the

overheat

lock-out

state

by

pressing

the

re-set

button

. See

Fig

. 34. If it still

does

not

light,

set

the

Operating Switch

or

Programmer to

OFF

and

then

back

to

WATER

as

the

gas

line will need

to

be

fully

purged

of

air

. If ignition still

does

not

take

place

after

several

attempts

contact Worcester Heat Systems

Ltd.,

Technical Inform-

ation

Department

With

the

boiler lit, hot water

at

a flow of 12.5litres/ min_ ( ± 15%)

(2.8 gallons/ min.)

is

delivered

at

a

full

temperature within a few

seconds.

Gradually close the

tap

and

check

that

the

burner pressure drops.

Fully open

the

tap

and

check

that

the

burner pressure rises.

Shut

the tap

and

check

that

the burner goes

off

-

the

fan may con-

tinue to run for a short period of time.

Set

the

Operating Switch (

or

Programmer) to

OFF.

Central

Heating Mode

Set

the

Operating Switch (or Programmer) to

HEATING

&

WATER.

The appliance should light in a few seconds

at

a burner pressure of

1

.3

mbar. The burner pressure

will

remain

at

this figure for

about

tWo

minutes

and

then increase over one minute to its factory

set

figure of

about

2.8

mbar

which is equivalent to a

heat

ing load of

15kW

(51

,200 Btu/

h)

. If a greater

heat

output

up

to a maximum of

25kW

(85

,300 Btu/

h)

is required, then

the

burner

pr

essure

must

be

adjusted

at

the

potentiometer located

at

the rear of

the

control

18

box

. See

Fig

. 27. Adjust

the

potentiometer to give a burner pres-

sur

e of 7.8 mbar. This figure

can

only

be

achieved if

the

burner

pressures are correctly set

in

the domestic hot

water

mode.

It is not necessary to set

an

outp

ut between these figures because

of the modulating effect of

the

controls.

Reposition

and

fix

the

control box.

Check

the

system to ensure

that

all the radiators are heating

up

evenly.

Shut down all the radiators

but

one

and

observe

the

burner pres-

sure

fall.

Open a

ll

of

the

radiator valves

and

check

that

the burner

pressure rises.

Balance

th

e system

so

that

the

requir

ed

temperature difference

across

the

heating flow

and

return pipes is obt

ained

releva

nt

to

the

heating load. See

Table

3.

Shut

all

the

radiators and adjust the by-pass until

the

sam

e tem-

pera

ture difference

is

obtained. See

Fig.

28.

Set

the

room thermo

stat

to minimum

and

check

that

the

burner

goes o

ut

Res

et

the

room thermostat to

max

i

mum

. After a fixed off period

of about three minutes the burner w

ill

re-light

and

follow t

he

no

r-

mal operating procedure.

'fum

off

the

electricity supply to the appliance. Drain the heating

system

as

described in Section 14.3 (

a)

.

Refill

and

repressurise as

described in

Se

ct

ion

11

.2

adding a suitable proprietary inhibitor.

Further information

can

be

obtained from Worcester Heat Sys-

tems.

Domestic

Hot

Water

and

Central

Heating

Mode

'fum on

the

electricity supply to

the

appliance.

Set

the

Operating Switch to

HEATING

&

WATER.

If

a programmer

is fitted

set

the

central heating to

24

Hours

and

the

domestic hot

water to

ON.

Check

the

operation of the domestic hot water supply by opening

a hot

tap.

Shut

the

hot

ta

p

and

the

burner

will

go off.

The appliance

wi

ll

return to

the

central heating mode after a fixed

off period of

ab

o

ut

three minutes

and

will

then automatically bal-

ance with

the

system requirements.

Set

the

Operating Switch (or Programmer) to

OFF

and

the

burner

will go

out

and

the fan

will

overrun for a few seconds.

11.6

COMPLETION

OF

COMMISSIONING

.

Disconnect

the

pressure gauge

and

tig

hten

the

te

st

po

int screw.

Restart

the

appliance

and

check for gas soundness around the

tes

t

po

int screw.

Refit

the inner cover

pane

l

and

the

cabinet front panel.

If

the

appliance is being passed over to

the

user immediately, refer

to Section 12

and

set

the

controls to the user's requirements.

If

the

applia

nce is

to

be

left inoperative,

then

chec

k

th

at

the

Operating Switch

or

Progra

mme

r

is

set

to

OFF

. 'fum

the

gas

ser-

vice cock to off

and

switch off

the

electricity supply.

If

there is

any

possibility of

the

appliance

and

system being left

in-

ope

rative during frosty conditions

the

n drain t

he

appliance

and

system.

If

there is

any

possibility of frosty conditions

then

the

appliance

should

be

left under

the

control of a frost

thermostat

or wi

th

the

system operating continuously with

the

room

ther

mosta

t

set

at

6 0

(_

Loading...

Loading...