DCC-XP V6

Rack control

with integrated condensation pressure control

Page 4 of 4 Subject to technical changes DCC-XP_V6.5.0_PI_2021-08_EN

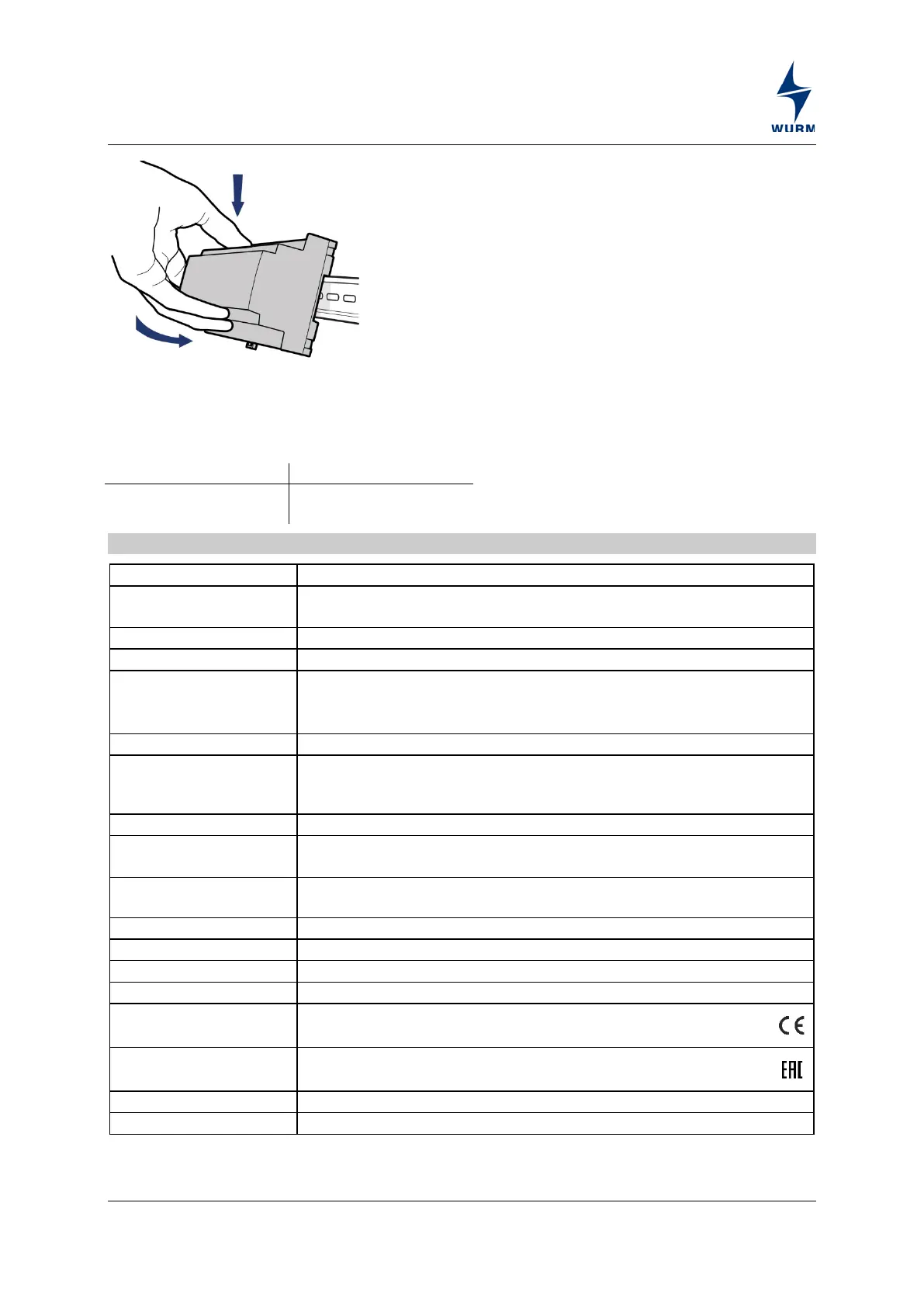

Place the device with the upper guide edge

on the top-hat rail.

Then press the device gently downward until

it engages with the fastening safety catch on

the top-hat rail.

For wiring of the data lines, we recommend the use of standard telephone lines 2x2x0.8ø up

to lengths of 100m. The shielding must be grounded in the control cabinet. For cable lengths

from 100m to 400m, shielded lines with braided sheathing should be used.

We recommend the use of shielded cables for sensor extension.

Technical data

230V~, +10% / -15%, 5VA approx.

0

: -0.5...7bar (corresponds to 4...20mA);

p

c

: 0...25bar (corresponds to 4...20mA)

0...10V= (for output control in voltage control operating mode)

Digital inputs

floating

1 x setpoint increase (∆T

0

), 1 x Fastreturn (FR)

2 x peak load shedding (I and II) of which 1 x multifunctional input (II)

4 x normally open contact, 230V~, 4(2)A, rated voltage 230V~

0...10V=, non-isolated, max. load 10mA, for connection of ADC

(multiple contact switch), speed regulator or frequency converter for

condensation pressure control

Single-chip microcomputer, data memory

Monitoring of connected sensors,

Self-monitoring of data memory and microcomputer

3-wire CAN bus interface with integrated power supply, galvanically

isolated, service socket

(WxHxD) 106 x 90 x 58mm (DIN 43880)

Top-hat rail TH 35-15 or TH 35-7.5 (DIN EN 60715)

Operation: 0...+55°C, storage: -25...+70°C

CE conformity

− 2014/30/EU (EMC Directive)

−

2014/35/EU (Low Voltage Directive)

EAC conformity

−

Loading...

Loading...