11

12

5. If power outage occurs during the processing, start the software after the system is

powered on again. The system will automatically load the processing file loaded before

the power outage and recover the saved information of the interrupted line. You can click

“START” to resume the interrupted processing after the loading is completed. In the case

of sudden power outage, as long as you don’t press the “stop” button, when you restart

the software and click “START” again, the system will continue the interrupted processing.

3-3 SELECTION AND REPLACEMENT OF MILLING BUR

Bur replacement is very important in the daily processing. It will directly affect the equip-

ment safety and processing quality. Therefore, careful operation is required. When the

bur has been used for a period of time or affects the processing quality, you need to

replace the bur according to the following steps:

1. Execute the “home” function to ensure that system has been homed.

2. If the current bur is not the bur for replacement, you can click the corresponding bur

button under manual mode to remove the target bur. When the bur is removed, click

“SECOND REFERENCE” to move the axes to the reference position.

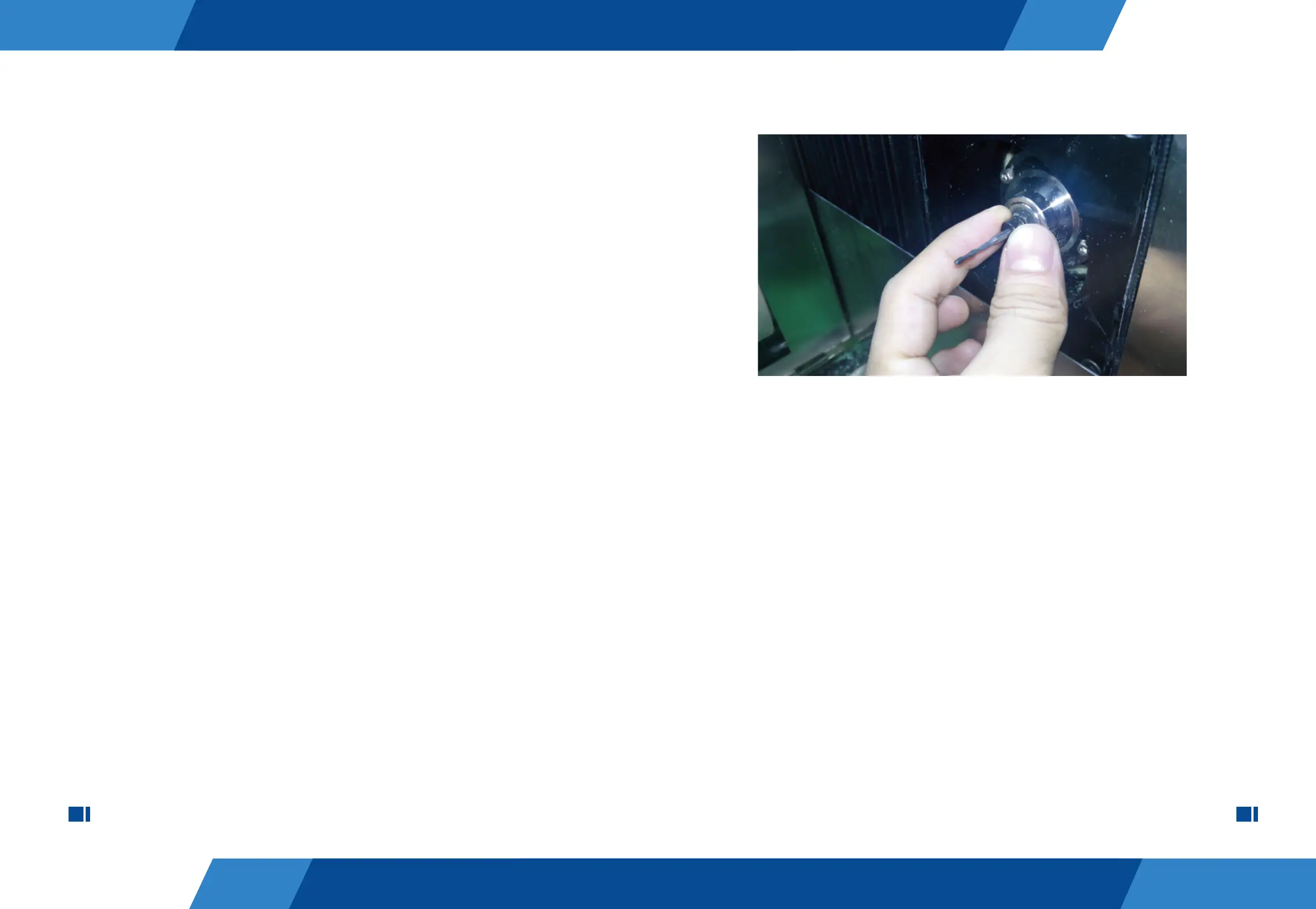

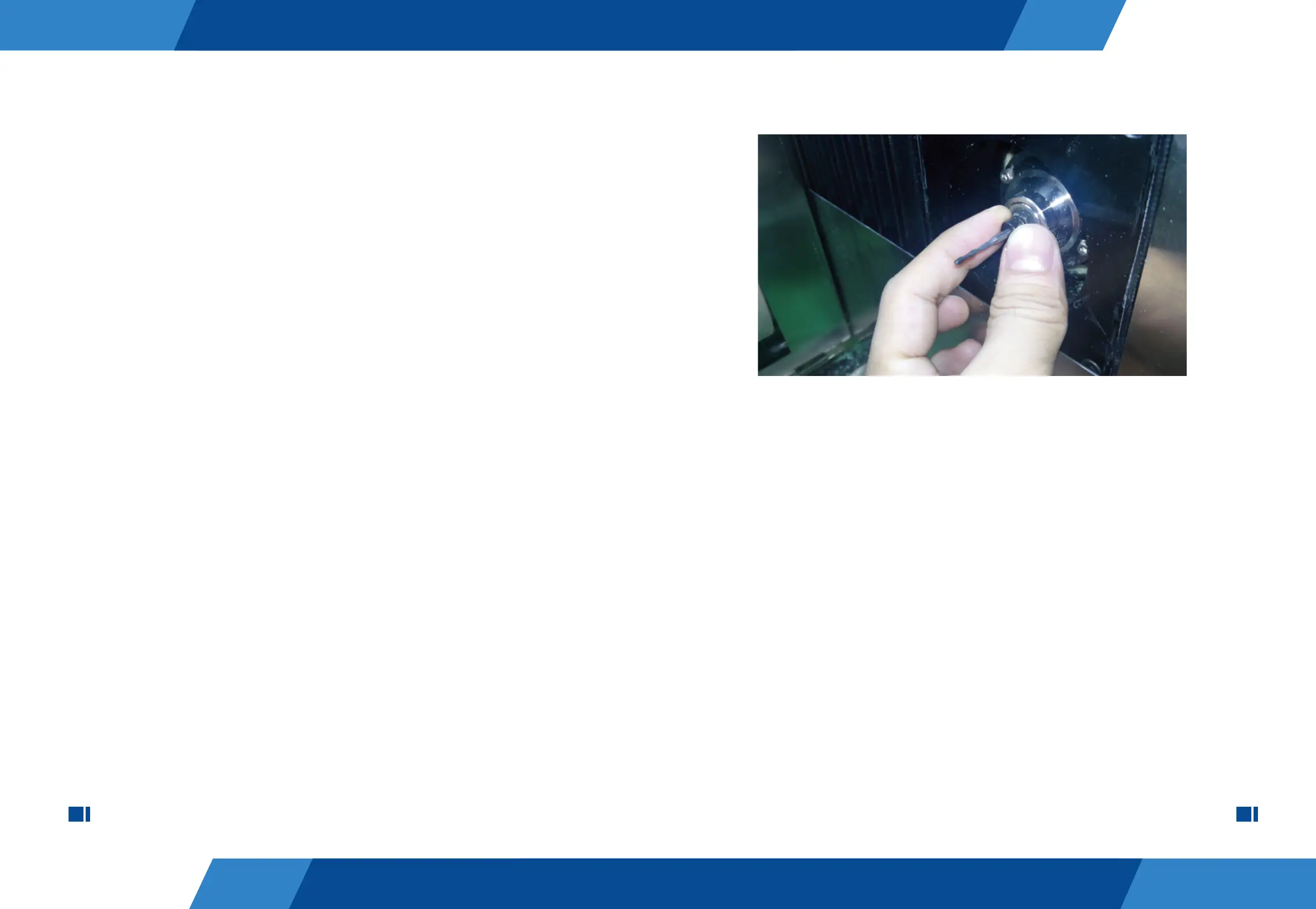

3. Use left hand to hold tight the milling bur before loosen the spindle chuck to avoid

any injury from the ejected bur( same as picture below ) . Please remember, the equip-

ment shall not be operated simultaneously by several persons. Even when it is operated

by a single person, special care shall be taken in each step, in order to avoid any person-

al injury due to the activation of spindle by mistake.

4. The new milling bur is equipped with collar. Insert the bur handle into the spindle

chuck, ensuring that the collar is against the chuck. Tighten the chuck after it is in position.

The collar is designed to ensure that the bur installation depth meets the equipment

processing requirement. Do not put bur without collar into the chuck or magazine. Now

the bur replacement is completed.

If too much part of the bur is exposed, the tool-cashing will be caused when it turns

over, damaging the magazine. Therefore, the installation position of the bur with collar

must be specified. When the bur is replaced, you shall manually turn it over to check if the

position is correct, in order to avoid any exception.

5. Key points for installation: (Mark the position) to ensure that the exposed part is kept

at the same position each time. Check if there is enough space in the magazine for the

bur twice each day. If not, replace it with a new bur with collar.

Loading...

Loading...