Operation Manual71

Preventive Maintenance

Establishing a Maintenance Program

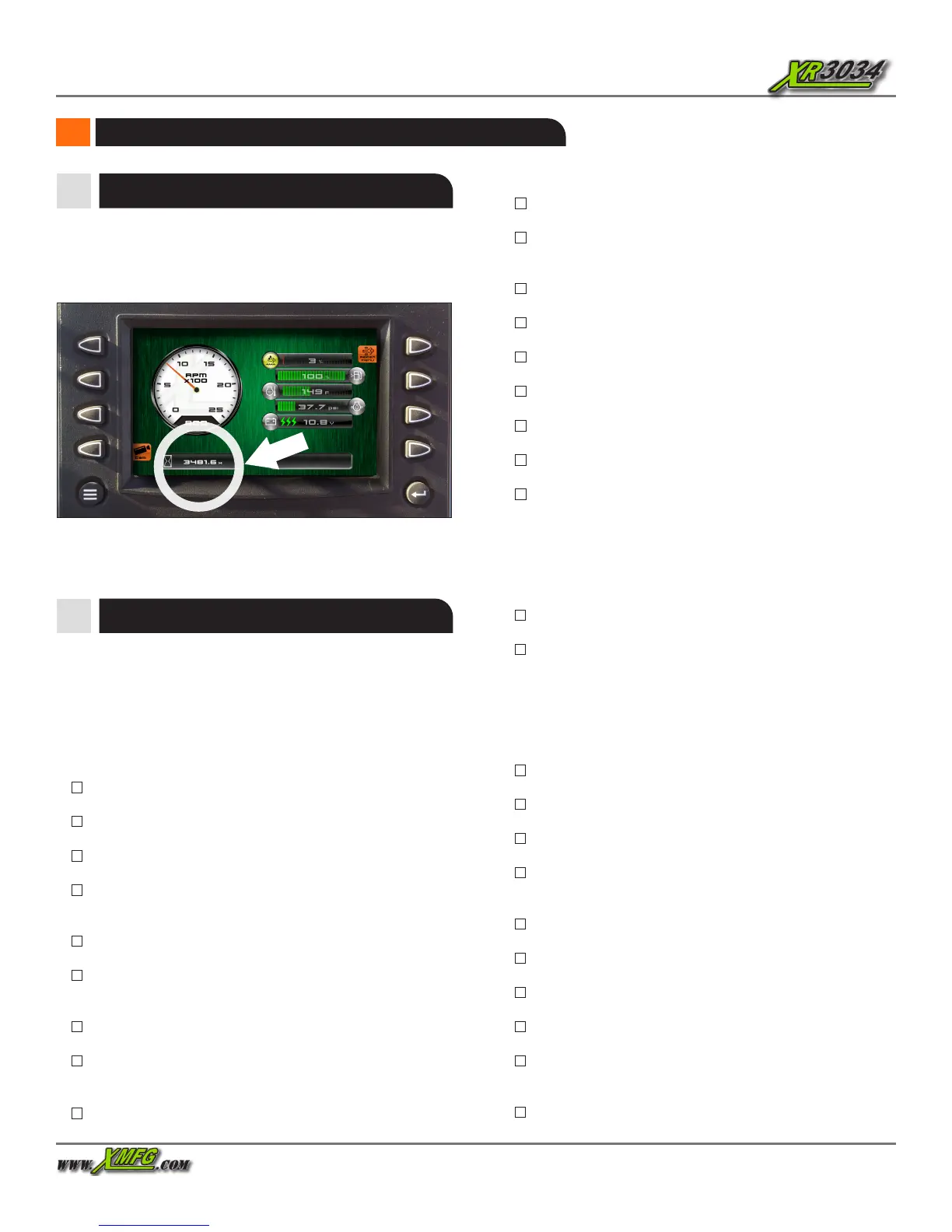

The hourmeter displays elapsed engine operating hours. Use

the hour meter and the schedules contained in this section to

establish a comprehensive preventive maintenance program.

Fig 90. Hourmeter

Maintenance Schedule

Change engine oil and lters

Check air lter (replace if necessary)

Replace fuel lter and prelter

Check engine hoses and connections for leaks,

damage, and tightness

Check radiator hoses for leaks, damage, and tightness

Check electrical cables, leads, and connections for

damage and tightness

Check for oil and coolant leaks

Check condition and tension of drive belts (use

tension meter to check belt tension)

Lubricate front and rear driveshaft grease ttings

Lubricate front and rear axle grease ttings

Lubricate front and rear axle cylinder pivot point

grease ttings

Change dierential oil

Change wheel-end oil

Check wheel lug nuts torqued to 380-420 ft lbs

Lubricate boom pivot point grease ttings

Lubricate boom roller grease ttings

Replace hydraulic return line lters

Replace transmission lter and top o uid, as

required

Every Day or 8 Hours of Operation

See Pre-Operation Inspection Checklist

After First 50 Hours of Operation

Lubricate boom pivot point grease ttings

Lubricate front and rear axle cylinder pivot point

grease ttings

After Every 50 Hours of Operation

Comply with 50-Hour Maintenance Requirements

Change engine oil and lter

Check air lter (replace if necessary)

Check tension and condition of drive belts (use

tension meter to check belt tension)

Lubricate front and rear drive shaft grease ttings

Lubricate front and rear axle grease ttings

Check dierential oil level

Check wheel-end oil level

Inspect boom rollers and slide blocks for condition

and tightness

Lubricate boom roller grease ttings

After Every 250 Hours of Operation

Preventive Maintenance

Loading...

Loading...