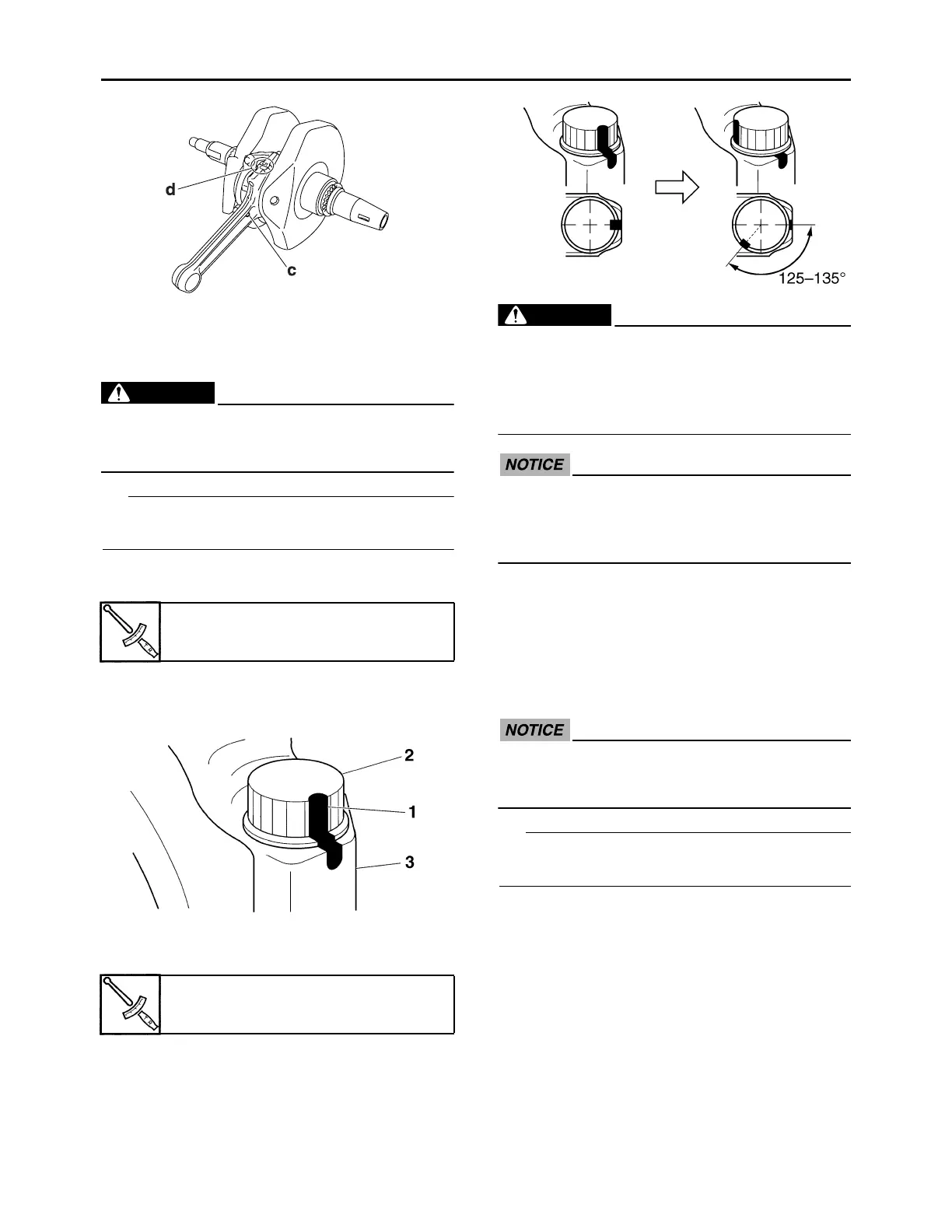

CRANKSHAFT

5-72

4. Tighten:

• Connecting rod bolts

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

WARNING

EWA5S71002

• Replace the connecting rod bolts with

new ones.

• Clean the connecting rod bolts.

TIP

Tighten the connecting rod bolts using the fol-

lowing procedure.

a. Tighten the connecting rod bolts to specifi-

cation with a torque wrench.

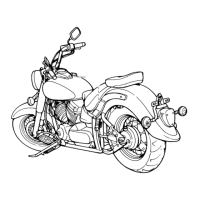

b. Put a mark “1” on the corner of the con-

necting rod bolt “2” and the connecting rod

cap “3”.

c. Tighten the connecting rod bolts further to

reach the specified angle 125–135°.

WARNING

EWA5S71003

When a bolt is tightened more than the

specified angle, do not loosen and then

retighten it.

Replace the bolt with a new one and per-

form the procedure again.

ECA5S71003

• Do not use a torque wrench to tighten the

bolt to the specified angle.

• Tighten the bolt until it is at the specified

angle.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS26210

INSTALLING THE CRANKSHAFT ASSEM-

BLY

1. Install:

• Crankshaft assembly

ECA5S71004

To avoid scratching the crankshaft and to

ease the installation procedure, lubricate

each bearing with engine oil.

TIP

Align the right connecting rod with the rear cyl-

inder sleeve hole.

Connecting rod bolt (1st)

15 Nm (1.5 m·kgf, 11 ft·lbf)

Connecting rod bolt (final)

Specified angle 125–135°

Loading...

Loading...