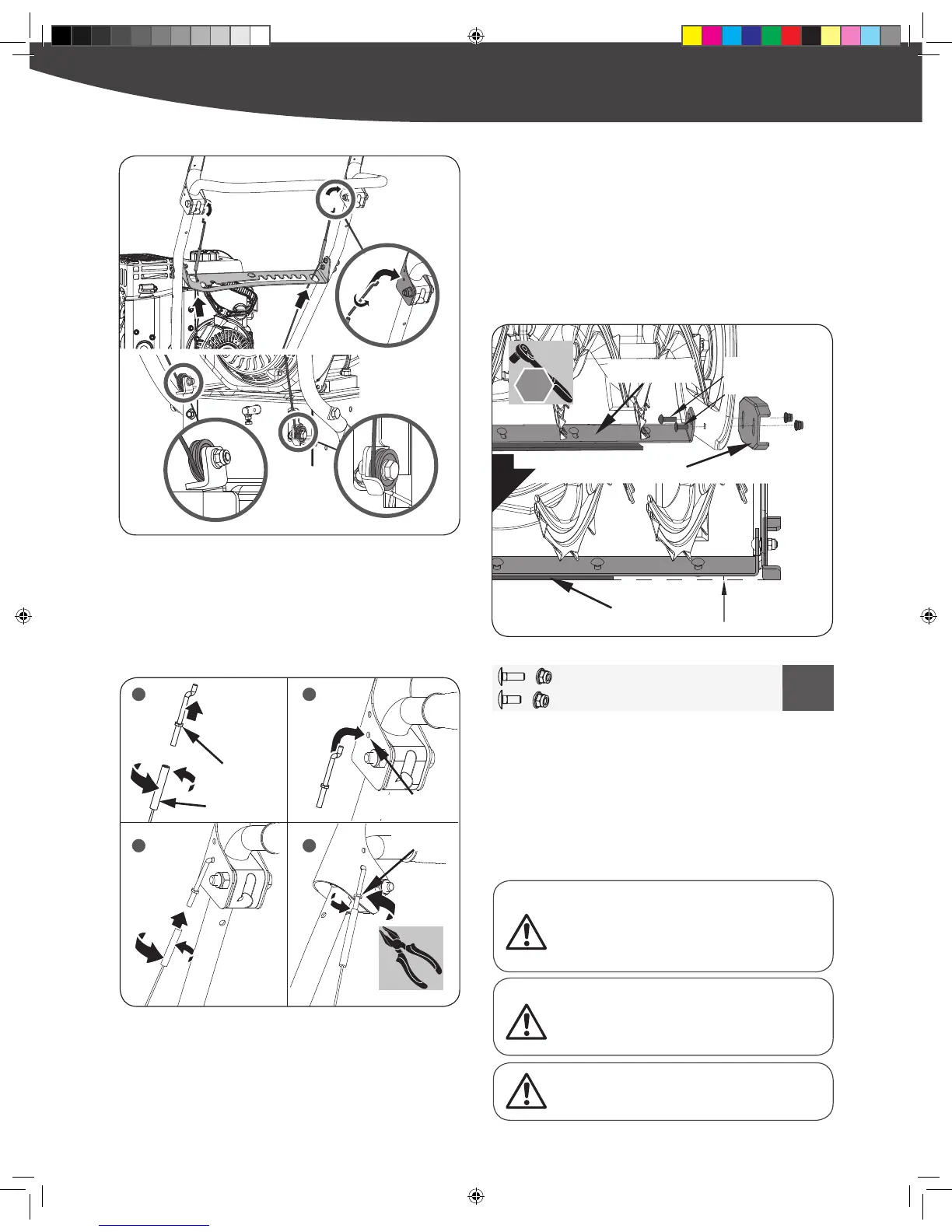

SKID SHOES

3

1.

4.

2.

2.

Lift the machine so that the scrapper blade is 1/8” (3mm)

above the ground, ensuring it is level. A piece of cardboard

half the thickness of the snow blower packaging placed

under the scrapper blade is recommended.

Attach the skid shoes to the sides of auger housing with the

bolts and nuts. The shorter M8X20 bolts should be in the front

holes while the longer M8X25 bolts in the rear holes. Move

the skid shoes down as far as possible. Be sure both skid shoes

are adjusted evenly. Tighten securely. (See

Figure 8

)

Place the machine is on a level and solid surface.

Remove the 1/8” (3mm) spacer you used from under the

scrapper blade.

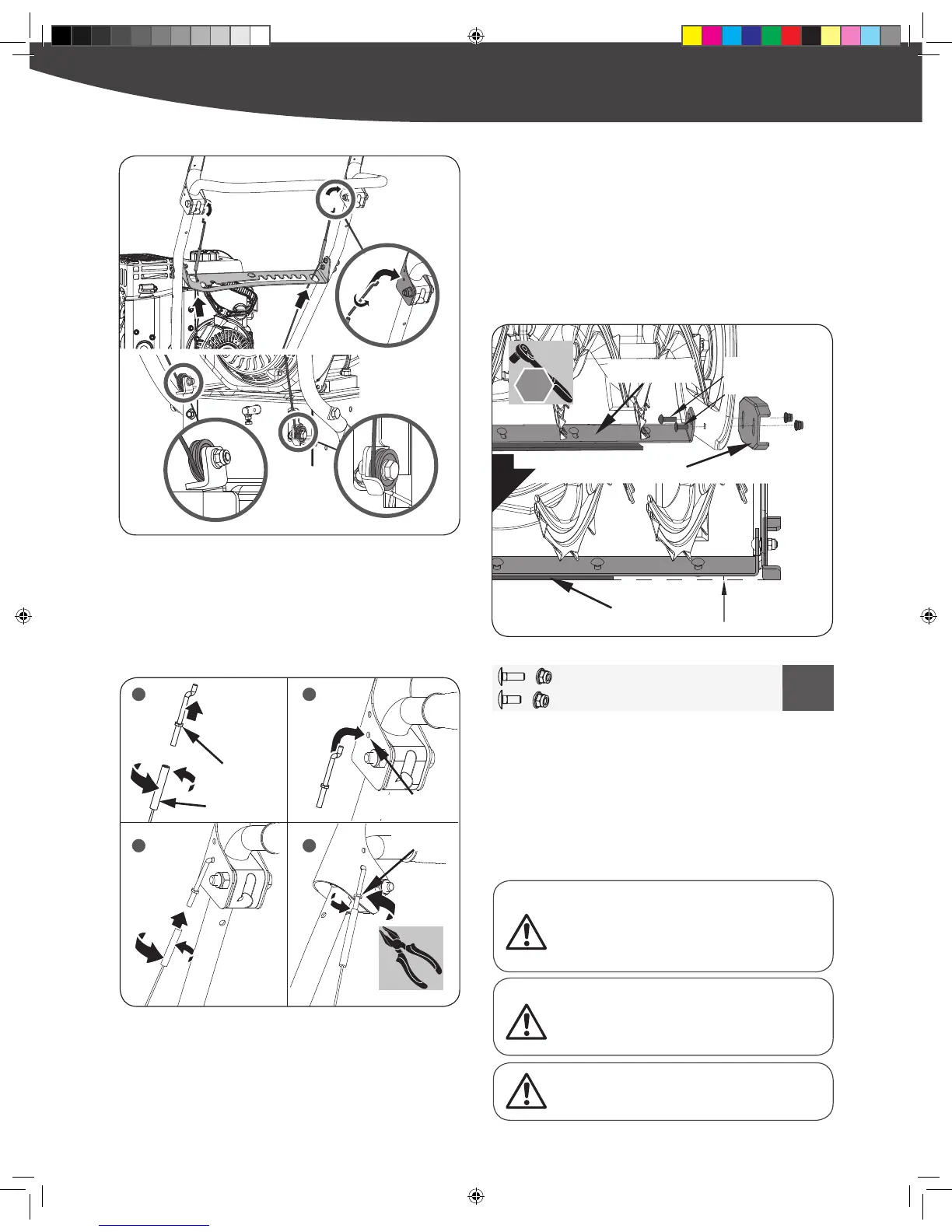

Disconnect the Z-fittings from the turnbuckles and hook

them into the lower holes in the clutch levers. Thread the

turnbuckles without turning the cables onto Z-ttings until

there is no slack in the cables. Do not overtighten the cables.

Hold the ats on the turnbuckles with pliers and tighten the

jam nuts against the turnbuckles. (See

Figure 7b

steps 1 – 4)

Figure 8

M8x25 X 2

6

M8x20 X 2

TIRES

The tires are over-inflated at factory for shipping purposes.

Check the pressure in the tires prior to usage. Reduce or increase

air pressure to ensure equal tire pressure to the manufacturer’s

recommended pressure. The recommended air pressure can be

found on the tire sidewall.

Figure 7a

Figure 7b

Under any circumstance do not exceed manufacturer’s

recommended pressure. Excessive pressure when

seating beads may cause tire/rim assembly to burst

with force sufficient to cause serious injury. Refer to

side wall of tire for recommended pressure.

Equal tire pressure should be maintained at all times. If

the tire pressure is not equal in both tires, the machine

may not travel in a straight path and the scraper blade

may wear unevenly.

Keep tires free of gasoline and oil, which can harm

rubber.

Loading...

Loading...