8600

9500

7800

Frequency(Hz) (High/Standard/Low)

70/41/15

63/44/15

80/57/15 75/65/15 100/60/15 100/60/15100/60/15

Nominal heating capacity (ID 70/60 OD 47/43F)

Standard Set-up Tested in Lab-Heating capacity (ID 70/60 O D17/15F)

Standard Set-up Tested in Lab-Heating capacity (ID 70/60 O D 5F)

11000

13000

8900

16400

25000

14500

17800

26000

15400

24800 31600

26500 34600

21200 26800

100/60/15

Conne-

ction

Pipe (In)

oo

15FT115F

oo

5FT86F

Outdoor

Unit

(ODU)

Starting Method

o

Recommended Working Ambient Temp Range (F)

Condenser Coil Type

Coil-Copper Pipe Diameter (In)

Rows-FPI

Coil Length (L) x Height (H) x Depth (D) (In)

Fan Motor Speed (rpm) (H/L)

Output of Fan Motor (W)

Fan Motor RLA (A)

Fan Motor Capacitor (uF)

Air Flow Volume of Outdoor Unit CFM

Fan Type-Piece

Fan Diameter (In)

Defrosting Type

Designed for Climate Type

Isolation

Moisture Protection

Sound Pressure Level dB (A) (H/M/L)

Sound Power Level dB (A) (H/M/L)

0.28

2-18.2

Transducer starting

Aluminum fin-copper tube

23.9X20.0X1.7

900/650

900 20

40

0.17

(DC)

1120

Axial-1 Axial-1 Axial-1 Axial-1

15.7

Auto defrost

T1

I

IP24

551

174

53

63

Transducer starting

Aluminum fin-copper tube

29.4X20X1.7

900/680

900 20

40

0.17

1120

15.7

Auto defrost

T1

I

IP24

551

174

55

65

0.35

Transducer starting

oo

15FT115F

oo

5FT86F

Aluminum fin-copper tube

0.28 0.28 13/16 3/8

33.0x26.0x1.5

690/500

60

0.62

3

1890

20.5

Auto defrost

T1

I

IP24

551

174

54

64

Transducer starting

Aluminum fin-copper tube

38.1x29.4x1.5 37.5x29.5x1.5 37.0x30.0x1.7

780/500 830 830

90 90 120

0.90 0.45 0.45

4 5 5

2480

21.7 21.75 21.75

Auto defrost

T1

I I

IP24 IP24

551 560

174 170

56

66

oo

15FT115F

oo

5FT86F

oo

15FT115F

oo

5FT86F

MAX. Operating Pressure for the Discharge Side (PSIG)

MAX. Operating Pressure for the Suction Side (PSIG)

Liquid Pipe (In)

Gas Pipe (In)

ID Above/Blow OD (Ft.)

Length (Ft.)

Outer Diameter

Max Distance

25

1/4

3/8

70

25 25

1/4 1/4 1/4

3/8

75

25

1/2 5/8

100 100

(DC)

Air Flow Volume (CFM) (SH/H/M/L)

300/277/253/218

500/460/383/324

560/471/412/353

Indoor

Unit

(IDU)

WMMS-09E-V2A/B(58) (2)

1300/1060/920/740 1320/1200/1100/960

WMMS-12E-V2A/B(58) (2)

1300/1080/900/740 1300/1160/1040/920

WMMS-18E-V2B(58) (2) WMMS-24E-V2B(58) (2)

1350/1200/1050/900

1420/1250/1150/1050

Dehumidifying Volume (Pints/Hr.)

1.7

2.5 4.2

5.5 6.3 7.4

1400/1150/1100/850 1400/1150/1100/900

Model of Indoor Unit

Fan Motor Speed (RPM) (SH/H/M/L)

Output of Fan Motor (w)

Input of Heater (w)

Fan Motor Capacitor (uF)

Fan Motor RLA(A)

Fan Type-Piece

Fan Wheel Diameter-Length (In)

Evaporator Coil Type

Coil-Copper Pipe Diameter (In)

Row-FPI

Coil length (L) x Height (H) x depth (D) (In)

Swing Motor Model

Output of Swing Motor (W)

Fuse (A)

Sound Pressure Level dB (A) (SH/H/M/L)

Sound Power Level dB (A) (SH/H/M/L)

Model of Outdoor Unit

Compressor Manufacturer

Compressor Model

Compressor Type

L.R.A. (A)

Compressor RLA(A)

Compressor Power Input(W)

Overload Protector

Throttling Method

20

/

4.0 / 1.0

0.38 / 0.20

Cross flow fan-1

3.6 X 25.4

Aluminum fin-copper tube

0.28

2-18.2

25.4X1X10.5 25.4X1X10.5

MP24AA

2.4

PCB 3.15A

38/34/30/26

48/44/40/36

WMMS-09C-V2A/B(58) (2)

SANYO / MITSUBISHI

C-6RZ110H1A

Twin Rotary DC Twin Rotary DC Twin Rotary DC Twin Rotary DC

33

4.59

800

Electronic Expansion Valve

WMMS-18C-V2B(58) (2) WMMS-24C-V2B(58) (2)WMMS-12C-V2A/B(58) (2)

3.6 X 25.4

20

/

4.0 / 1.0

0.38 / 0.20

Cross flow fan-1

Aluminum fin-copper tube

MP24AA

2.4

PCB 3.15A

40/36/32/26

50/46/42/36

SANYO / MITSUBISHI

C-6RZ110H1A

33

4.59

800

Electronic Expansion Valve

0.28

2-18.2

20

/

1.5

0.25

Cross flow fan-1

3.9 X 28.0

Aluminum fin-copper tube

0.28

28.1X12X1

MP28VB

2.5

PCB 3.15A Transformer 0.2A

46/44/40/35

56/54/50/45

SANYO / MITSUBISHI

SANYO / MITSUBISHI

C-6RZ146H1A

41

8.4

1640

1NT11L-3979

1NT11L-39791NT11L-3979

Electric Expansion Valve

EER (Btu/h.w)

14.0

12.5

12 12

Rated Current (A) (High/ Standard)

SEER / HSPF (Btu/h.w)

A:13.5/7.0 B:6.5/3.2

22

A:14.5/7.5 B:6.8/3.5

9.8

A:14.5/11 B:7.0/5.2

20

A:15.5/12.5 B:7.5/6.0

9.6

13.2/8.6 17.2/12.4 17.4/12.7 18.2/15.1 18.2/15.512.7/8.2

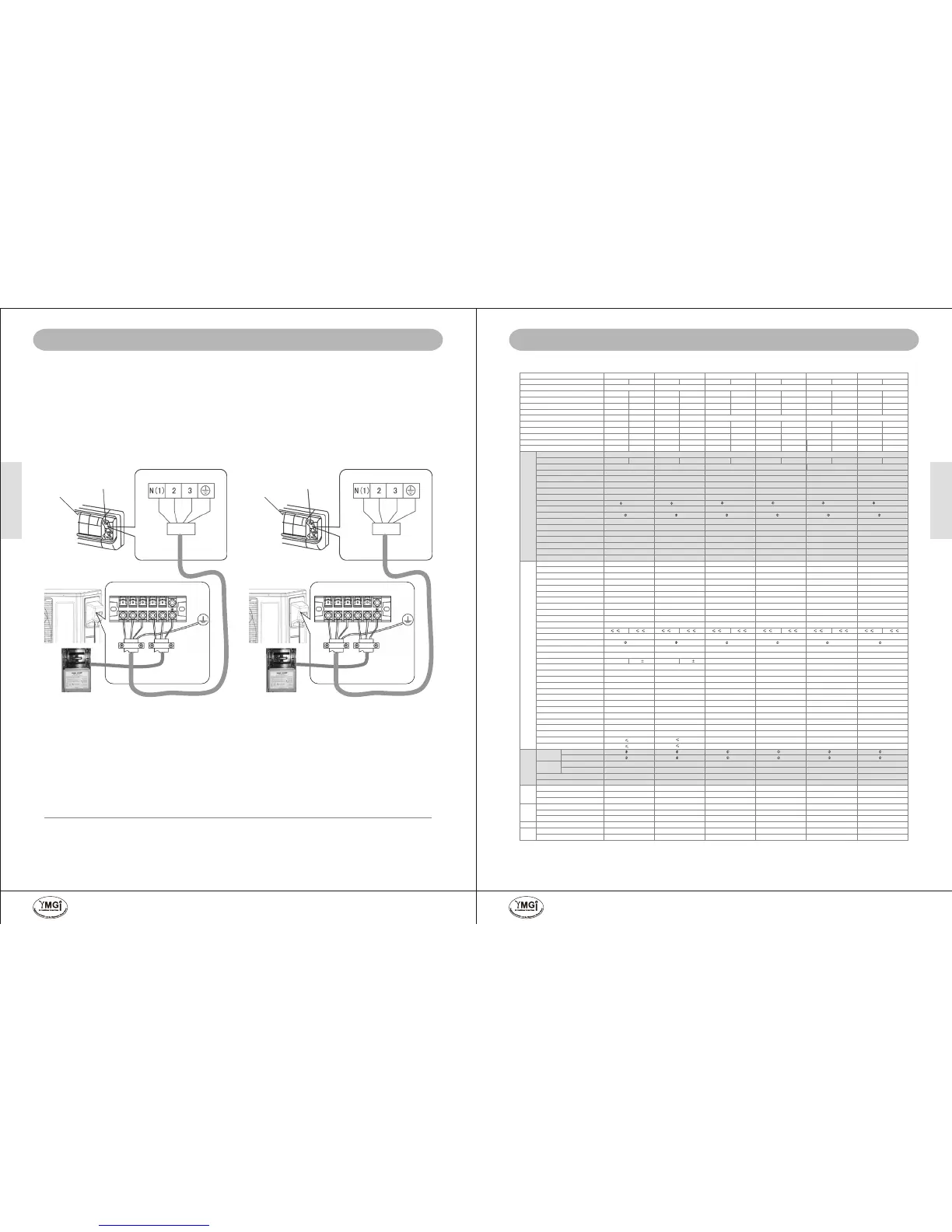

System Model

Functions

Power Soure

COOLING

208~230/1/60

HEATING

WMMS-24K-V2B(58) (2)

COOLING

A:115/1/60 B:208~230/1/60

HEATING

WMMS-09K-V2A/B(58) (2)

COOLING

A:115/1/60 B:208~230/1/60

HEATING

WMMS-12K-V2A/B(58) (2)

COOLING

208~230/1/60

HEATING

WMMS-18K-V2B(58) (2)

12.56/7.712.0/7.5

Power Input (W) (High/ Standard/Low)

1050/660/180 1100/700/220 1450/1000/120 1500/1200/220 2750/1790/500

3450/2780/550 3500/2370/700 3800/3650/610 3700/3560/970

2650/1700/400

2550/1600/3352500/1500/300

18.0

10.2

18.0

35

/

2.5 3.5 3.5

0.45

Cross flow fan-1

3.9 X 30.1 4.25 X 41.0 4.25 X 41.0

Aluminum fin-copper tube

0.28

30.1X13.5X1 42.25X15X1 42.25X15X1

MP35XX MP24BA MP24BA

2.5

PCB 3.15A Transformer 0.2A

48/44/40/35

58/54/50/45

C-6RZ146H1A

TNB220FLHMC

41 45 67

8.4

1640 2200 3010

1NT11L-3979 CS01F272H01 CS01F272H01

Electric Expansion Valve

A:30 B:20 20

30 30 40

Fuse Circuit Breaker of HVAC Type

35/45 35/45

50/60 50/60

2-18.2 2-16.9 2-19 2-19

2-18.2 2-18.2 2-18.2 2-1.4 2-1.4

WMMS-30K-V2B(58) (2) WMMS-36K-V2B(58) (2)

WMMS-30E-V2B(58) (2) WMMS-36E-V2B(58) (2)

HEATING

COOLING

HEATING

COOLING

208~230/1/60 208~230/1/60

58/-/56

68/-/66

59/-/57

69/-/67

Capillary Capillary

oo

5FT86F

oo

15FT115F

oo

5FT86F

oo

15FT115F

Transducer starting Transducer starting

Aluminum fin-copper tube Aluminum fin-copper tube

Axial-flow Axial-flow

T1 T1

1/4 1/4

5/8 5/8

I

IP24

560

170

Automatic Defrosting Automatic Defrosting

WMMS-30C-V2B(58) (2) WMMS-36C-V2B(58) (2)

MITSUBISHI MITSUBISHI

125 125

25 25

2860 2860

50/60 50/60

/

Cross flow fan-1

Aluminum fin-copper tube

0.28

2 2

PCB 3.15A Transformer 0.2A PCB 3.15A Transformer 0.2A

52/50/48/40 52/50/48/40

62/60/58/50 62/60/58/50

Aluminum fin-copper tube

0.28

Cross flow fan-1

/

16 168.2 8.2

10 9.2

740/670/640/580 740/670/640/580

40

0.4 0.4

40

TNB306FPGM

Rotary DC Rotary DC

9.7 13.5

1400/1300/1200/1000 1400/1300/1200/1000 1400/1300/1200/1000 1400/1300/1200/1000

Total Capacity (Btu/h) (High/ Standard/Low)

10600/9000/4435 11100/9500/3200

14000/12000/4500

14500/13000/3250

26000/25600/1120025000/21500/960025000/19000/4100

22350/18000/6000

30000/28000/7400 33000/28500/10000 36000/33600/9500 36000/34600/15000

10.2

A:30 B:20

Dimensions-Net W x H x D (Inches)

Dimensions-Net W x H x D (Inches)

Dimensions of Carton Box W x H x D (Inches)

Gross / Net Weight (LBs)

Dim. &

Weight-

Indoor

Unit

33.3 x 10.8 x 7.1 33.3 x 10.8 x 7.1

36.0 x 14.0 x 10.0 36.0 x 14.0 x 10.0

31/24

31/24

37.0 X 11.7 X 7.9

39.8 X 15.0 X 11.2

37.5/28.7

39.7 X 12.4 X 8.6

42.2 X 15.6 X 12.3

46.3/35.3

Gross / Net Weight (LBs)

Dim. &

Weight-

Outdoor

Unit

33.4 x 21.3 x 12.6

34.6 x 22.8 x 14.2

90/79

33.4 x 21.3 x 12.6

34.6 x 22.8 x 14.2

97/88

Assumed-One Model/ContainerSets (20'/40'/40'HQ)

Safety Approval (Third Party)

Performance Approval (Third Party)

Container

Loading

Certification

109/232/252

ETL (C & US)

AHRI / Energy Star

109/232/252 60/125/145 47/96/114

ETL (C & US) ETL (C & US) ETL (C & US)

AHRI / Energy Star AHRI / Energy Star AHRI / Energy Star

35.0 X 27.6 X 13.4

40.6 X 28.9 X 18.1

121/110

36.2 X 31.1 X 14.6

41.9 X 33.1 X 19.0

132/119

36/75/92 36/75/92

60/4460/44

170/161163/155

38.5 X 31.3 X 16.8 38.5 X 31.3 X 16.8

42.5 X 33.3 X 19.3 42.5 X 33.3 X 19.3

53.1 X 12.8 X 10.0 53.1 X 12.8 X 10.0

56.6 X 16.5 X 13.5 56.6 X 16.5 X 13.5

ETL (C & US) ETL (C & US)

Dimensions of Carton Box W x H x D (Inches)

AHRI AHRI

330/295/253/218

If Not Marked on Nameplate, Refrigerant

Pre-charged for Copper Line Length

Check Pressure at Trial Running

Add or Deduct Refrigerant

0.28 0.32 0.38

0.32

0.54 0.54

BRIEF UNIT INFO

BRIEF UNIT INFO

P15 OF 38 P16 OF 38

MINI WALL MOUNT SYSTEMS - SPECIFICATION BRIEFS

Unit Specifications and Engineering Submittal

1. Performance rated for matched system at standard conditions-cooling ID 80/67F, OD 95F; heating ID 70/60F, OD 47/43F.

Unit performance varies when weather changes from the standard one.

2. Select equipment capacity sizes per space load calculation schedule and cooling & heating hours. Not to over size or under size equipment.

3. Watch unit operation during extreme weather conditions in summer and winter. baffle helps system cooling & heating performance in

low ambient temperatine ranges.

Wind

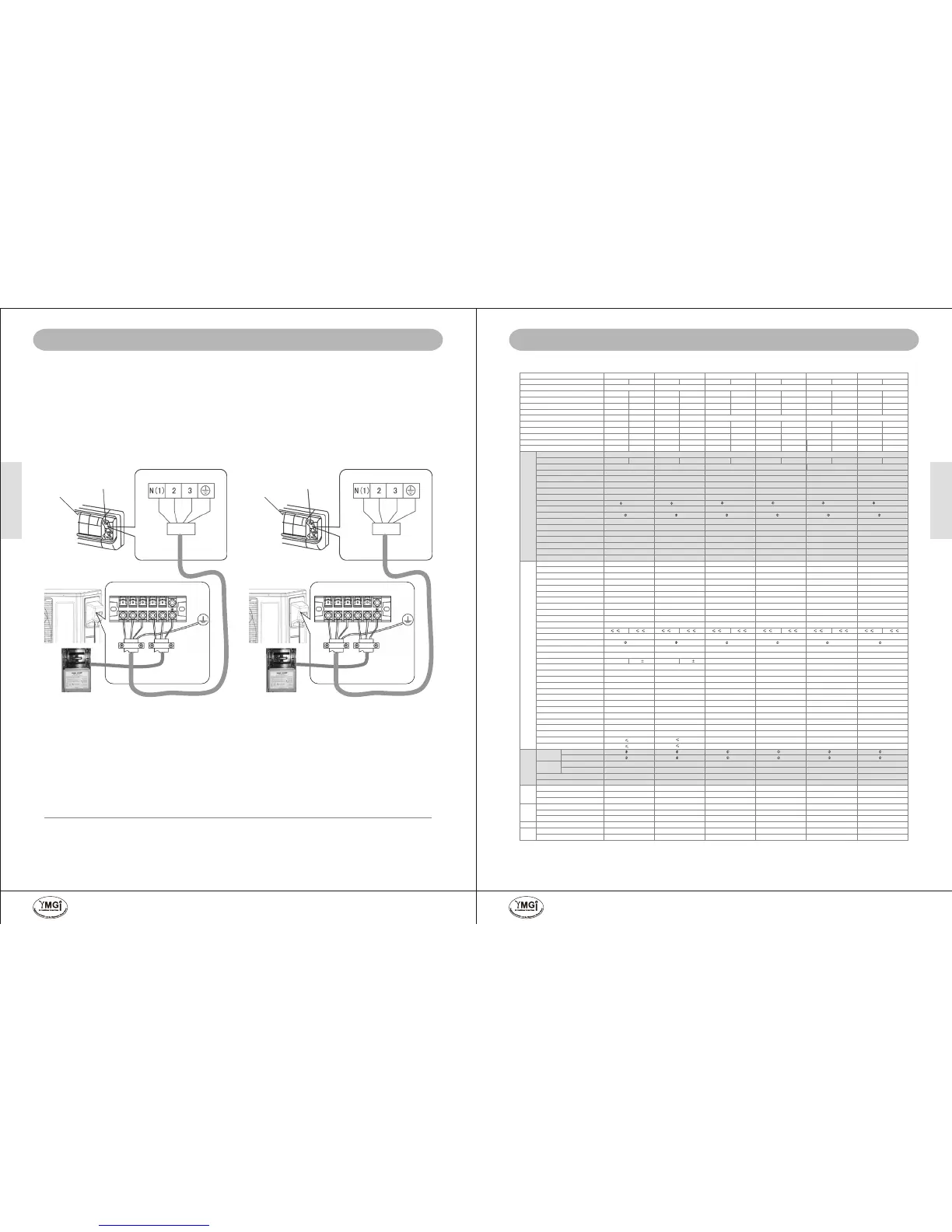

CONNECTION OF WIRES

Front (surface)

Panel

Note:

* The environment conditions must be taken into consideration when the connections of power cable are made

(such as the ambient temperature, direct exposure to heat exposure to sunlight).

* The specifications for the power cable refer to the minimum values of the metal core wires, taking into

consideration the voltage losses, the core wire of power cable must be one size larger than the specifications.

* The grounding wire must be connected to the indoor units and outdoor units.

* The laying of power cables must be done by qualified electricians and comply with the regulations of the local

power supply authorities and with the standards of the electric appliance.

09K/12K Models (115/1/60) 18K/24/30K/36K Models (208~230/1/60)

Wiring Cover

WIRING AT INDOOR UNIT AND OUTDOOR UNITS

* Open the front cover panel.

* Remove screws from electrical box cover and put screws in secured position.

* Remove screws from fastener and put screws in secured position.

* Prepare wires of right size and grade.

* Recommend to use factory-provided wire/cables.

* Connected to the terminals following wiring diagrams (terminal or color matches).

* Clamp power/control wires to the structure to keep the tension form being transmitted to the wire connection.

* Replace screws or fasteners back to where they were.

PIPING AND WIRING SIZES

Model

Liquid/Gas

Line

Min/Max.Length/

+/-Elevation

Power Wire Min.

Disconnect Switch Box to

Outdoor Unit

Power/ Control Wire Min.

Outdoor to Indoor Unit

Recommended HVAC

Circuit Breaker/Fuse

AMP (to Outdoor Unit)

09K

1/4" & 3/8"

15/70 /35/45

L/N/G, 115/1/60, 12AWG

N(1)/2/3/G, 115/1/60, 16AWG

20/30

12K

1/4" & 3/8"

15/75 /35/45

L/N/G, 115/1/60, 12AWG

N(1)/2/3/G, 115/1/60, 16AWG

20/30

18K

1/4" & 1/2"

15/100/50/60

L1/L2/G, 208-230/1/60, 10AWG

N(1)/2/3/G, 208~230/1/60, 16AWG

20

24K

30K

36K

1/4" & 5/8"

1/4" & 5/8"

1/4" & 5/8"

15/100/50/60

15/125/50/60

15/125/50/60

L1/L2/G, 208-230/1/60, 10AWG

L1/L2/G, 208-230/1/60, 8AWG

L1/L2/G, 208-230/1/60, 8AWG

N(1)/2/3/G, 208~230/1/60, 16AWG

N(1)/2/3/G, 208~230/1/60, 16AWG

N(1)/2/3/G, 208~230/1/60, 16AWG

30

30

40

Terminal block of

outdoor unit

(To power supply)

N(1)

2

3

L N

Indoor Unit

Outdoor Unit

Front (surface)

Panel

Wiring Cover

N(1)

2

3

L1 L2

Teminal block

of indoor unit

(To outdoor

unit)

Terminal block of

outdoor unit

(To power supply)

Indoor Unit

Outdoor Unit

Teminal block

of indoor unit

(To outdoor

unit)

Terminal matchTerminal match

YMGI, Engineered Comfort Products for A Sustainable and Efficient Green World !YMGI, Engineered Comfort Products for A Sustainable and Efficient Green World !

Loading...

Loading...