Appendix 3. Tuning Parameter Differences

App.3-12

TI 33K01B10-50E

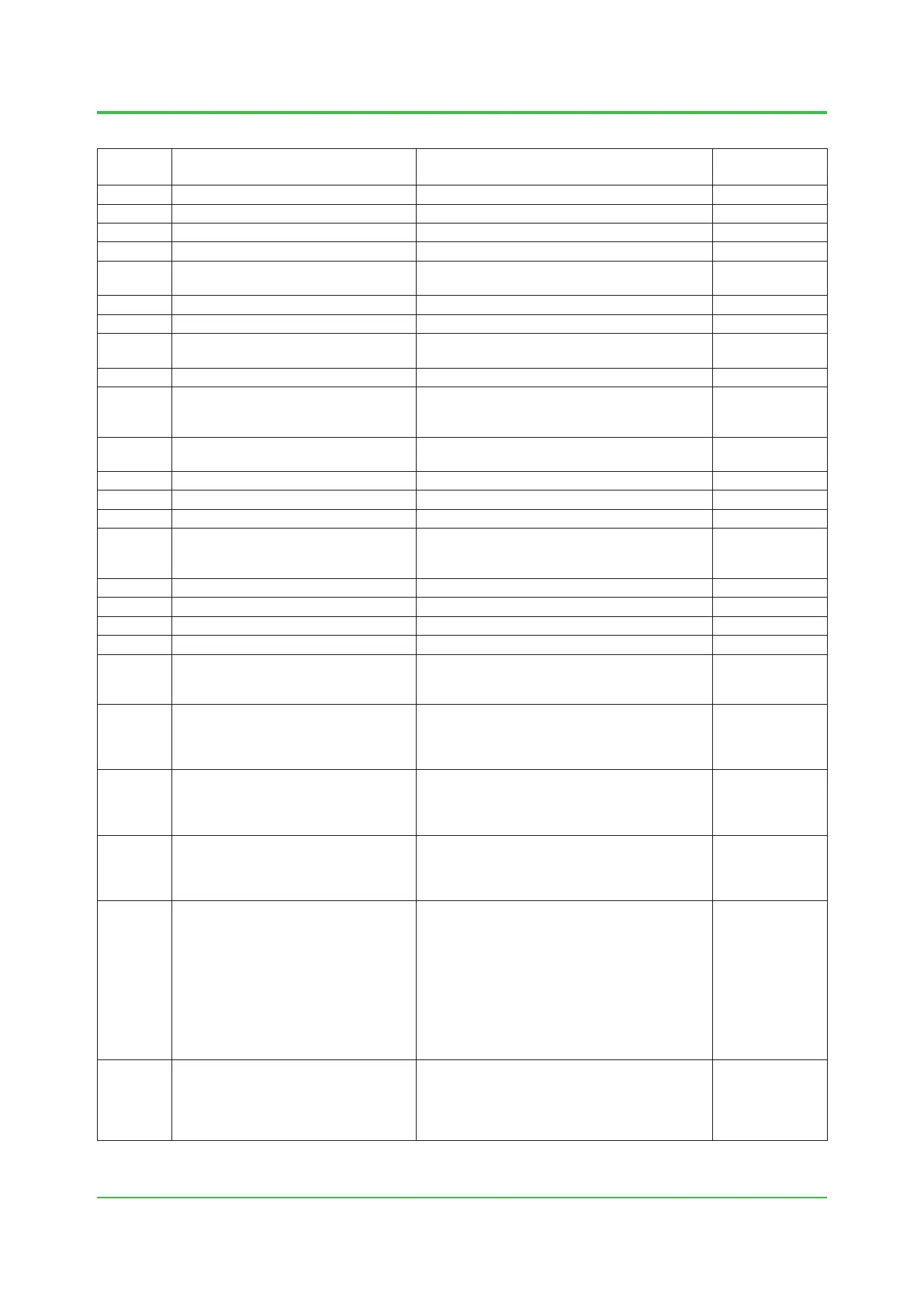

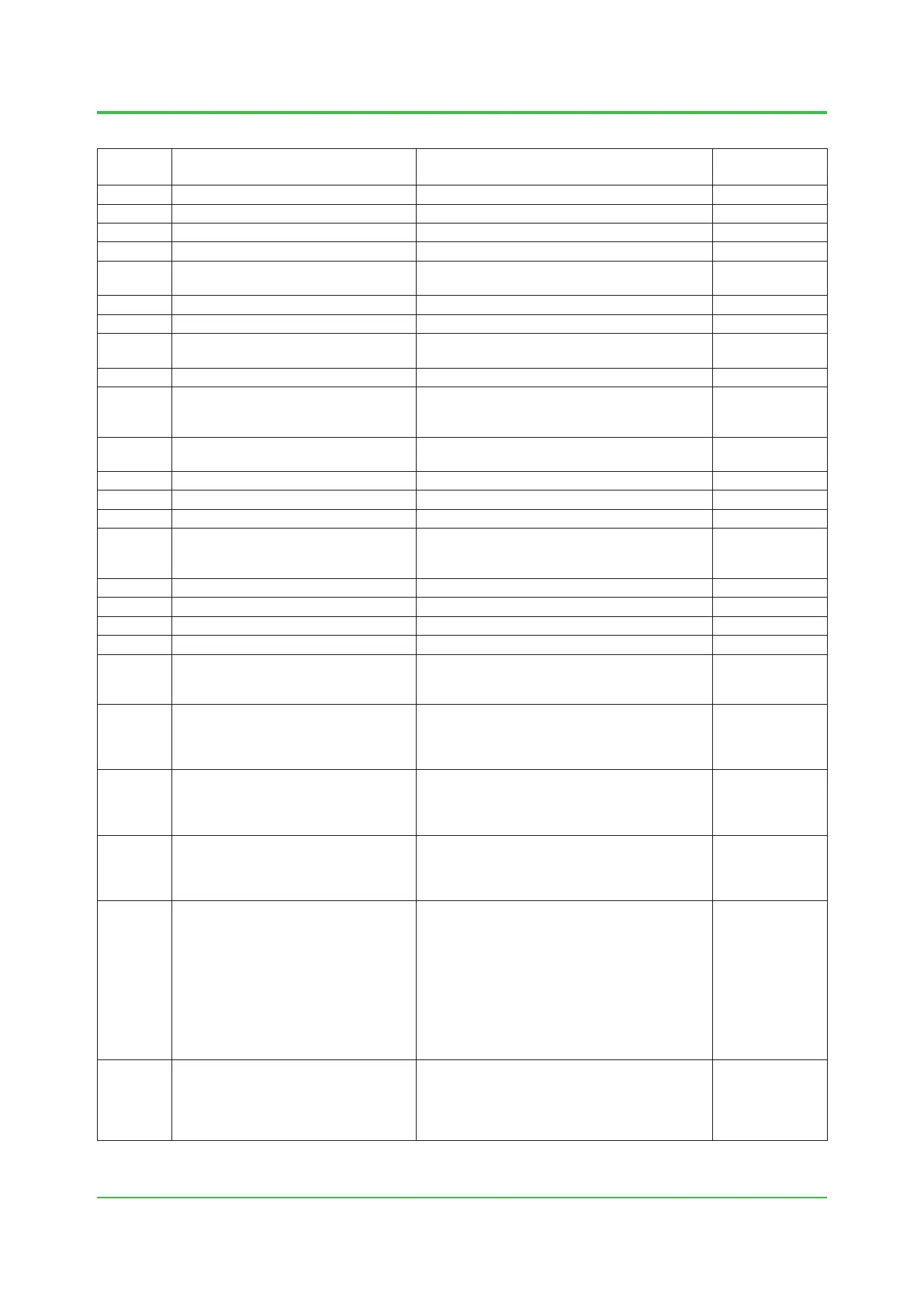

Table Equations for Tuning Parameters Requiring Conversion(1/2)

conversion

equation

Conversion Detail

Conversion Equation

(Y: converted; X: prior to conversion)

Remarks

(*1) Express MV range in engineering unit Y=(MSH-MSL) * X+MSL

(*2) Express DV span in engineering unit Y=(DSH-DSL) * X

(*3) Express PV span in engineering unit Y=(SH-SL) * X

(*4) Express MV span in engineering unit Y=(MSH-MSL) * X

(*5) Reverse 1 and 0

If(X==0)→Y=1

If(X==1)→Y=0

(*6) Express SV range in engineering unit Y=(SSH-SSL) * X+SSL

(*7) Express SV span in engineering unit Y=(SSH-SSL) * X

(*8)

Rate of change set value on UP/

DOWN side

Y=(X-SSL)/(SSH-SSL) * (MSH-MSL)

(*9) Number transfer Y=X-1

(*10) Bias calculation

BIAS=(BS/100+CS) * (MSH-MSL)

-{MSL/(MSH-MSL)}

+{SL/(SH-SL) * KP}

(*11) Switch position

If(X==1or2or3)→Y=X

If(X==4) →Y=3

(*12) Express PV range in engineering unit Y=(SH-SL) * X+SL

(*13)

Reectionoflinksourcerange No conversion No conversion

(*14) Conversion in input source range Y=X * (connecting range)

(*15) Response to 0, 1, and 2

If(X==0.0) →Y==0

If(X==50.0) →Y==1

If(X==100.0)→Y==2

(*16) Ratio gain KR=(SH-SL) * SSH/(MSH-MSL)/4 * KP KP=ratio gain

(*17) Batch set BSET=K8 * K9

(*18) Batch set ILST=PL * K9

(*19) Batch set PLST=DL * K9

(*20) PID parameter

In case of using D parameter, re-tuning of

PID is basically required because the D-term

calculation algorithm has been changed.

Refer to "4.5.3

Handling tuning

parameters."

(*21)

Sequence table, relational expression,

operational expression

There are difference in function as an

instrument (function block) rather than a

category of tuning parameter. (These are

automatically converted by the tool.)

Refer to "5.1.4

Comparison

of sequence

control function."

(*22) Internal switch

Take care that the switch number in the system

area is different. (This is the target of automatic

conversion by the tool.)

Refer to "5.1.4

Comparison

of sequence

control function."

(*23) Valve output monitoring

This parameter, which has been set in

[OperationCheckTime]ofthevalveoutput

monitoring builder in old FCS, is upgraded to

MTxx of VLVM in CENTUM VP.

(*24) Off-site instrument (BLEND)

BLEND and BLEND-1 instruments of

CENTUM-XL are integrated into the BLEND

block of CENTUM VP.

At this time, the interface from a

supervisory computer is also changed, thus

reimplementation of engineering is required.

Therefore, parameters with this conversion

number only indicates compatibility with XL-

to-VP upgrade, and is not actually the target of

conversion.

(*25) Alarm status

The basic alarm status still remains as ALRM.

CAL that was included in the conventional

alarm status is changed to the data status of a

process variable (such as &PV).

Refer to "5.1.2

Comparison

of function

block's common

function."

Mar. 27, 2015-00

Loading...

Loading...